Method for synthesizing supported ternary platinum alloy catalyst

A synthesis method and catalyst technology, applied in electrical components, battery electrodes, circuits, etc., to achieve the effects of mild conditions, simple operation, and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

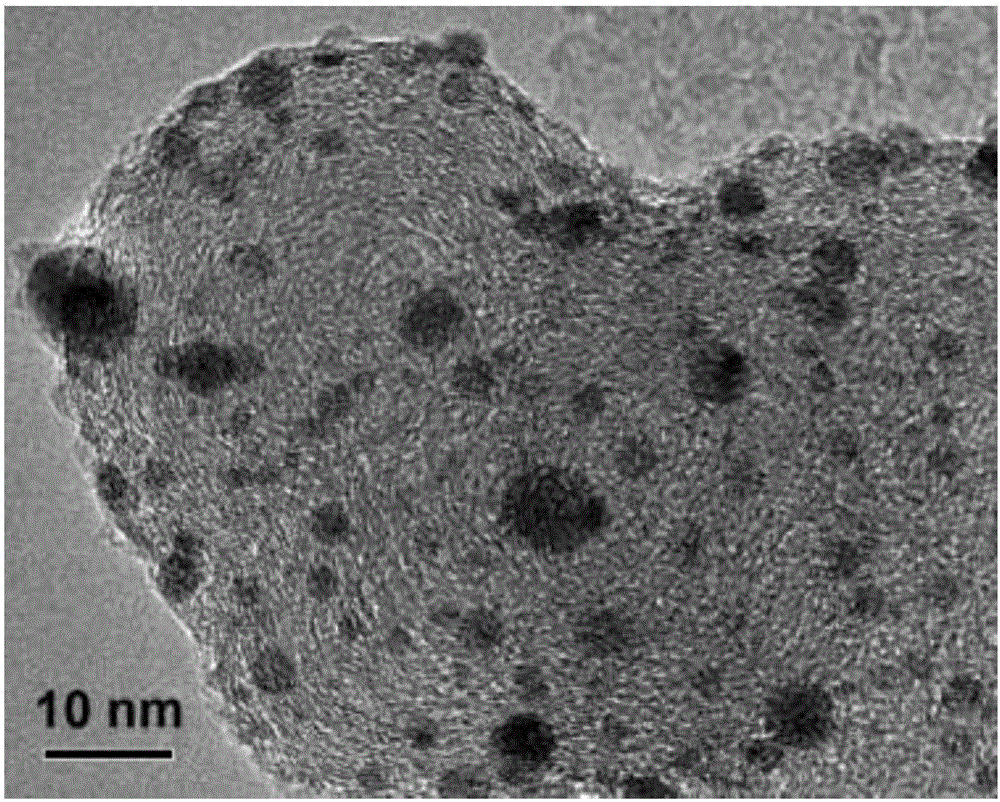

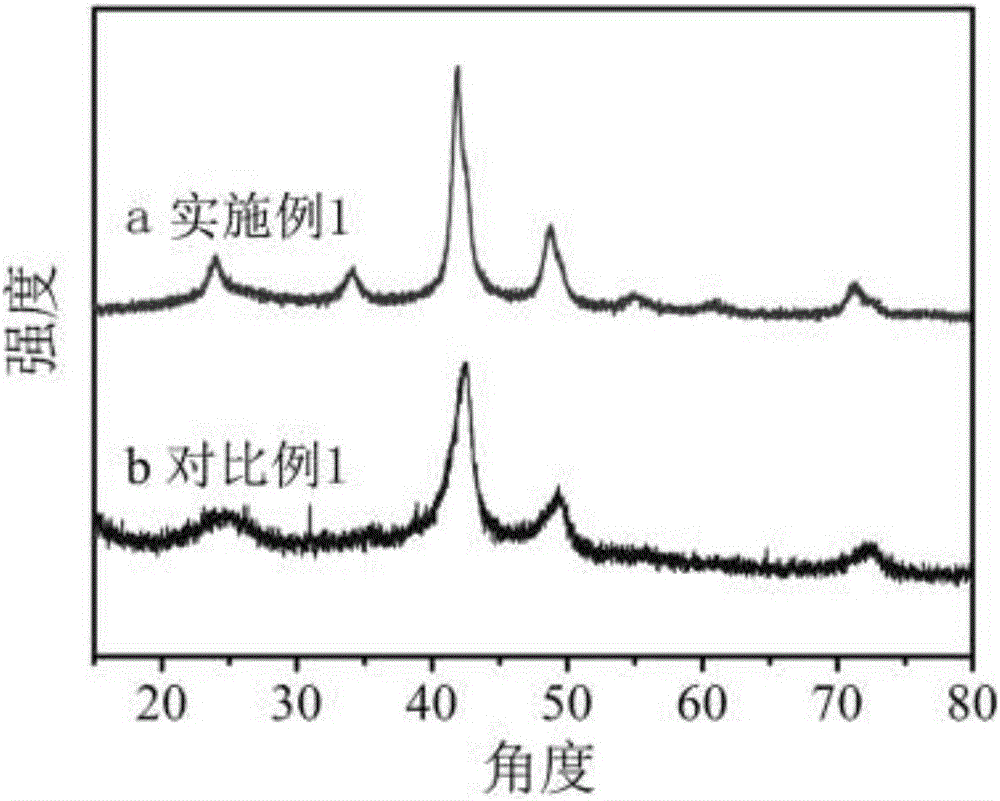

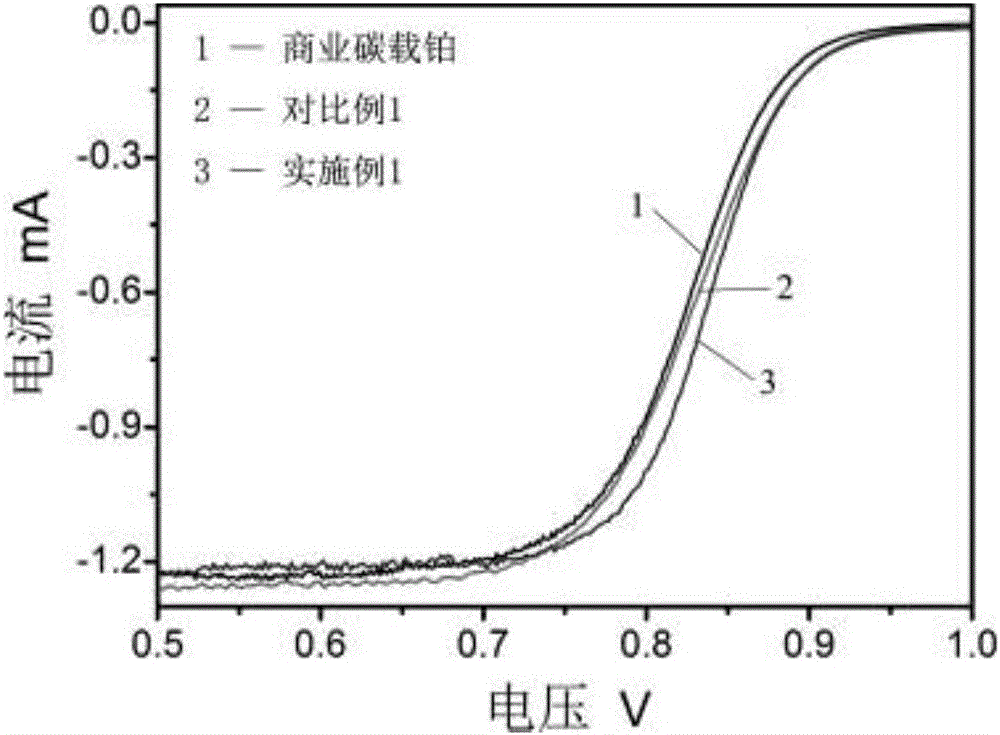

Embodiment 1

[0026] Weigh 100mgCuSO 4 ·5H 2 O, add a few drops of water to dissolve, then add 75mg of VulcanXC-72 carbon spheres and 120mL of ethylene glycol, and ultrasonically disperse for 60min. Then add 300mg NaBH rapidly 4 powder, stirred overnight at room temperature. NaBH 4 After complete decomposition, slowly add 2.4mL19.5mmol / LHAuCl to the above solution at a rate of 0.5mL / min using a peristaltic pump 4 , and continued stirring for 5 h after ultrasonication for 30 min. HAuCl 4 A substitution reaction occurs with Cu, and the generated Au nanoparticles cover the Cu surface, and the Cu 2+ diffuse into the solution. Since the amount of Au is relatively small, it cannot completely cover the surface of Cu nanoparticles, so the surface of Cu has enough space to accommodate other atoms. In order to further obtain the PtAuCu ternary material, we continued to drop 4.8mL19.5mMK in the same way 2 PtCl 4 solution. After the reaction, it was centrifuged, washed, and dried at room tem...

Embodiment 2

[0033] Weigh 100mgCuSO 4 ·5H 2 O, add a few drops of water to dissolve, then add 75mg of VulcanXC-72 carbon spheres and 120mL of ethylene glycol, and ultrasonically disperse for 60min. Then add 300mg NaBH rapidly 4 powder, stirred overnight at room temperature. NaBH 4 After complete decomposition, use a peristaltic pump to slowly add 1mL19.5mmol / LHAuCl to the above solution at a rate of 0.5mL / min 4 , and continued stirring for 5 h after ultrasonication for 30 min. Using the same method to continue to drop 7mL19.5mMK 2 PtCl 4 solution. After the reaction, it was centrifuged, washed, and dried at room temperature. Finally, the above materials were placed in H 2 / Ar atmosphere, calcination at 300°C for 30min to obtain Pt supported on carbon spheres 10 Au 3 Cu 46 Ternary alloy.

Embodiment 3

[0035] Weigh 100mgCuSO 4 ·5H 2 O, add a few drops of water to dissolve, then add 75mg of polypyrrole nanotubes and 120mL of ethylene glycol, and ultrasonically disperse for 60min. Then add 300mg NaBH rapidly 4 powder, stirred overnight at room temperature. NaBH 4 After complete decomposition, slowly add 2.4mL19.5mmol / LHAuCl to the above solution at a rate of 0.5mL / min using a peristaltic pump 4 , and continued stirring for 5 h after ultrasonication for 30 min. Using the same method to continue to drop 4.8mL19.5mMK 2 PtCl 4solution. After the reaction, it was centrifuged, washed, and dried at room temperature. Finally, the above materials were placed in H 2 / Ar atmosphere, calcined at 300°C for 30 min to obtain a PtAuCu ternary alloy supported by carbon spheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com