POSS composite porous gel polymer electrolyte and electrostatic spinning preparation method

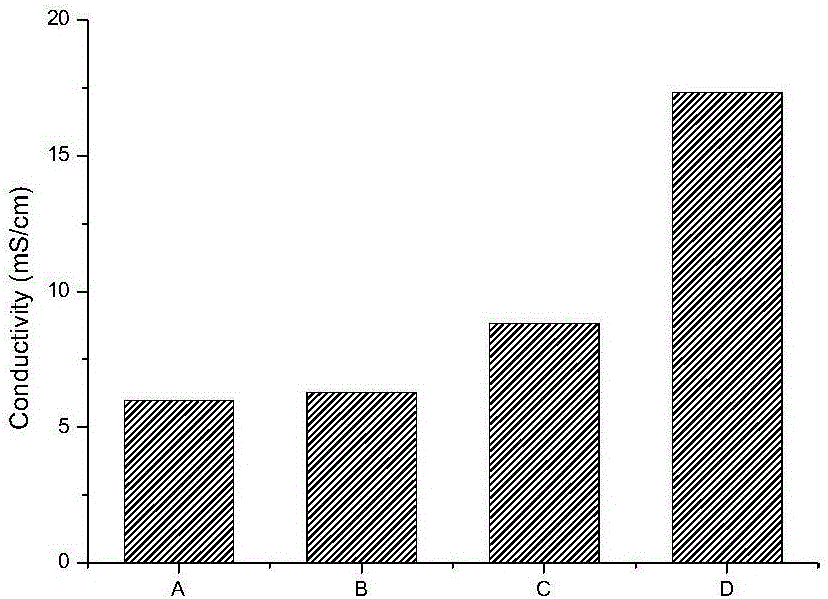

A gel polymer, electrospinning technology, applied in electrospinning, solid electrolyte, non-aqueous electrolyte and other directions, can solve the problems of short cruising distance and cycle life, poor rate charging and discharging performance, etc. Improves conductivity and avoids the effect of poor dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

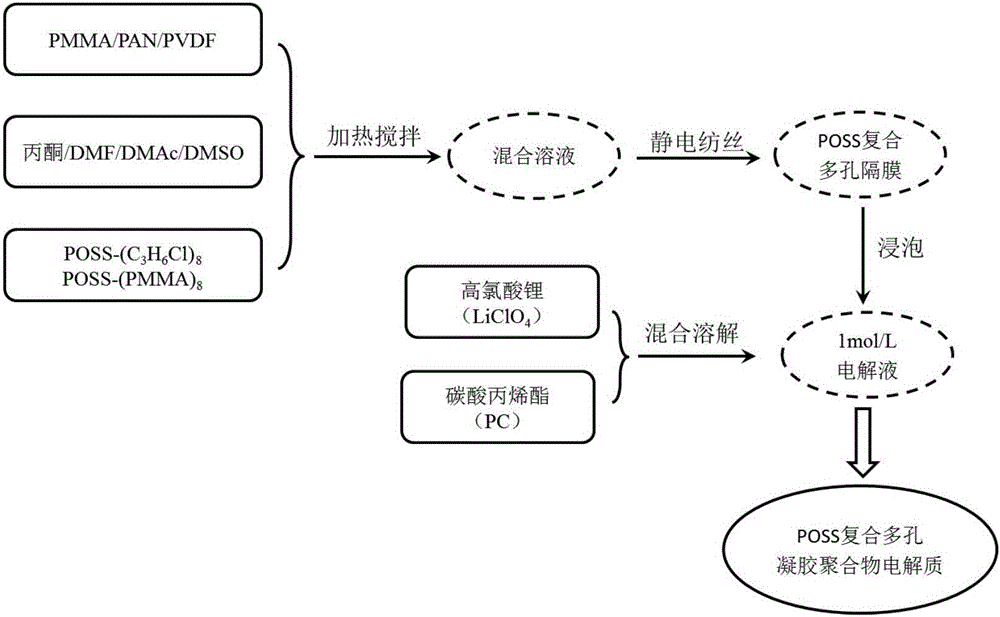

[0023] Implementation example 1: the reaction flow diagram is as figure 1 shown.

[0024] Step 1: PVDF and POSS-(C 3 h 6 Cl) 8 Dry in a vacuum oven at 60°C for 24 hours, and distill the polymer solvent DMF under reduced pressure and add Molecular sieves stand for more than 12h;

[0025] Step 2: Weigh DMF and PVDF according to the mass ratio of 85:15, heat and stir in a water bath at 30°C to form a polymer solution, and then weigh POSS-(C 3 h 6 Cl) 8 And blend with the above polymer solution, heat and stir until it dissolves completely to obtain a spinning solution;

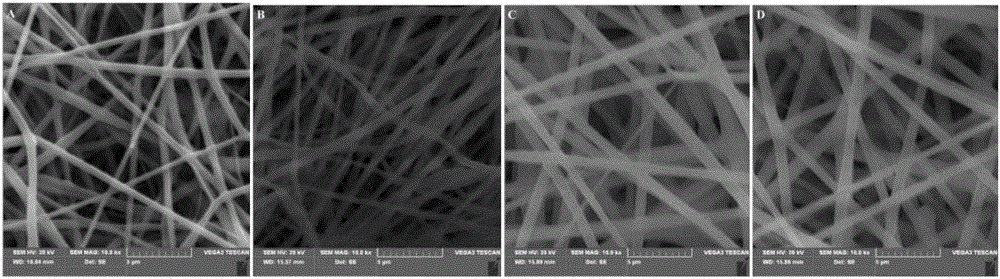

[0026] Step 3: Electrospinning the spinning solution in Step 2 to obtain a spun film, and drying it in a vacuum oven at 40° C. for 24 hours to obtain a POSS composite porous film. The parameters of the electrospinning are: the spinning voltage is 20KV, the injection speed of the spinning solution is 0.2mm / min, the needle of the syringe is 25cm away from the spinning receiving device, and the spinning rece...

Embodiment 2

[0029] Step 1: PVDF, PAN and POSS-(C 3 h 6 Cl) 8 Dry in a vacuum oven at 60°C for 24 hours, and distill the polymer solvent DMF under reduced pressure and add Molecular sieves stand for more than 12h;

[0030] Step 2: Weigh DMF, PVDF and PAN according to the mass ratio of 85:10:5, heat and stir in a water bath at 40°C to form a polymer solution, and then weigh POSS-(C 3 h 6 Cl) 8 And blend with the above polymer solution, heat and stir until it dissolves completely to obtain a spinning solution;

[0031] Step 3: Electrospinning the spinning solution in Step 2 to obtain a spun film, and drying it in a vacuum oven at 40° C. for 24 hours to obtain a POSS composite porous film. The parameters of the electrospinning are: the spinning voltage is 20KV, the injection speed of the spinning solution is 0.2mm / min, the needle of the syringe is 25cm away from the spinning receiving device, and the spinning receiving device is a drum with a rotating speed of 15m / h;

[0032] Step 4: ...

Embodiment 3

[0034] Step 1: PVDF, PAN and POSS-(C 3 h 6 Cl) 8 Dry in a vacuum oven at 60°C for 24 hours, and distill the polymer solvent DMF under reduced pressure and add Molecular sieves stand for more than 12h;

[0035] Step 2: Weigh DMF, PVDF and PAN according to the mass ratio of 85:10:5, heat and stir in a water bath at 40°C to form a polymer solution, and then weigh POSS-(C 3 h 6 Cl) 8 And blend with the above polymer solution, heat and stir until it dissolves completely to obtain a spinning solution;

[0036] Step 3: Electrospinning the spinning solution in Step 2 to obtain a spun film, and drying it in a vacuum oven at 40° C. for 24 hours to obtain a POSS composite porous film. The parameters of the electrospinning are: the spinning voltage is 18KV, the injection speed of the spinning solution is 0.25mm / min, the needle of the syringe is 20cm away from the spinning receiving device, and the spinning receiving device is a drum with a rotating speed of 15m / h;

[0037] Step 4: S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com