Mirabegron sustained release tablet and preparation method thereof

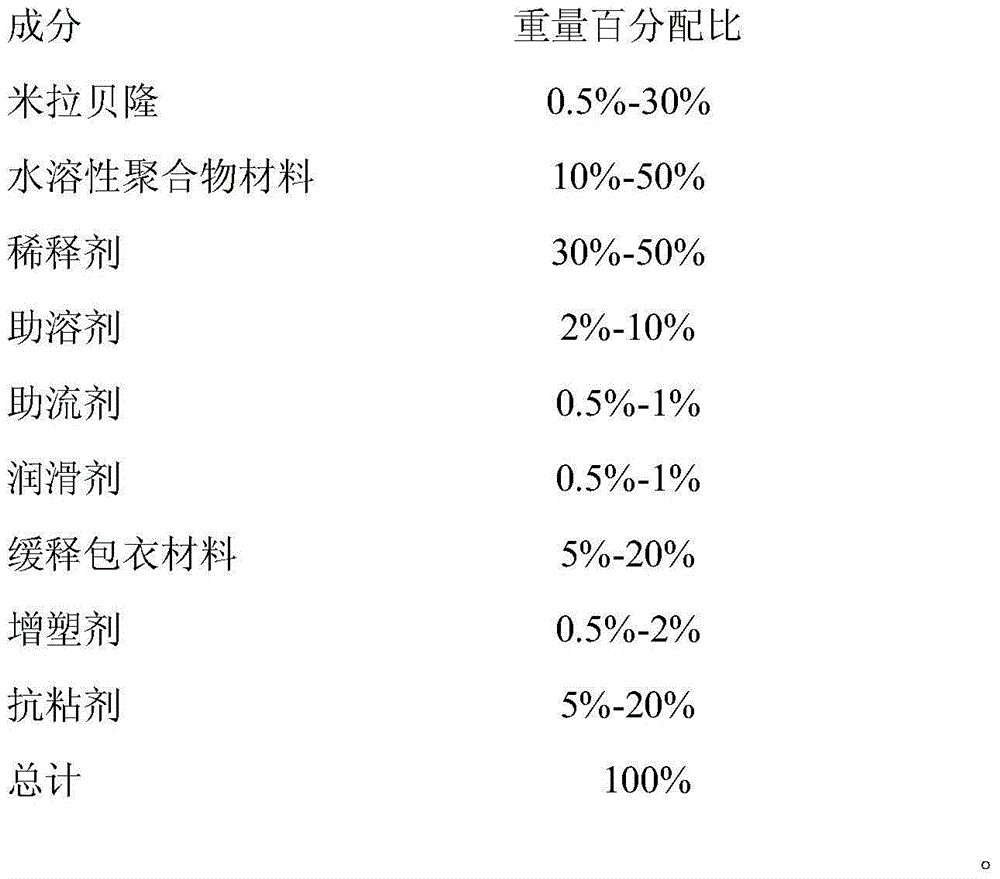

A technology of mirabegron and sustained-release tablets, which is applied in the direction of pharmaceutical formulas, medical preparations containing no active ingredients, and medical preparations containing active ingredients. Incomplete release and other problems, to achieve convenient clinical use, good clinical application prospects, and increase the effect of compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] formula Amount (g) Mirabellon 180

[0038] Hydroxypropyl methylcellulose E6 70 microcrystalline cellulose 210 Sodium dodecyl sulfate 30 silica 6 Magnesium stearate 6 Polyacrylic resin NE30D (30% water dispersion) 110 Triethyl citrate 12 talcum powder 62 total 686

[0039] Preparation steps: take 180 g of Mirabegron, 70 g of hydroxypropyl methylcellulose E6 and 30 g of sodium lauryl sulfate for micronization using an airflow pulverizer, the airflow pressure is 2.0 Mpa, the feed rate is 500 g / h, and the powder is pulverized. After the end, measure the particle size, D90 is 8.9um; add the above-mentioned micronized material into the hot melt granulator KJL-100, heat it to 150°C, stir evenly, add 28g of 80°C hot water for granulation to obtain wet granules, Cool to 28°C while stirring, and the weight loss on drying is determined to be 3.4%; add microcrystalline cellulose, silicon dioxide an...

Embodiment 2

[0046] formula Amount (g) Mirabellon 240

[0047] Hypromellose 200 lactose 250 Vitamin E TPGS 30 silica 6 Magnesium stearate 6 Ethyl cellulose aqueous dispersion (30%) 100 Triethyl citrate 10 talcum powder 58 total 900

[0048] Preparation steps: take 240 g of mirabegron, 200 g of hydroxypropyl cellulose and 30 g of vitamin ETPGS for micronization using an airflow pulverizer, the airflow pressure is 2.0Mpa, the feed rate is 700g / h, and the particle size is measured after the pulverization, D90 is 8.0um; add the above micronized material into a hot melt granulator, heat it to 180°C, stir evenly, add 55g of 80°C hot water to granulate to obtain wet granules, cool to 25°C while stirring, and measure the loss on drying The value is 2.4%; add lactose, silicon dioxide and magnesium stearate, stir for 10 minutes, and mix well to obtain the final mixture before tableting; use the Fette tablet machine to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com