Method for treating methionine production technology waste gas

A treatment method and methionine technology, applied in the field of waste gas treatment, can solve the problems of low efficiency and high cost of methionine waste gas treatment technology, and achieve the effects of small investment, low treatment cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

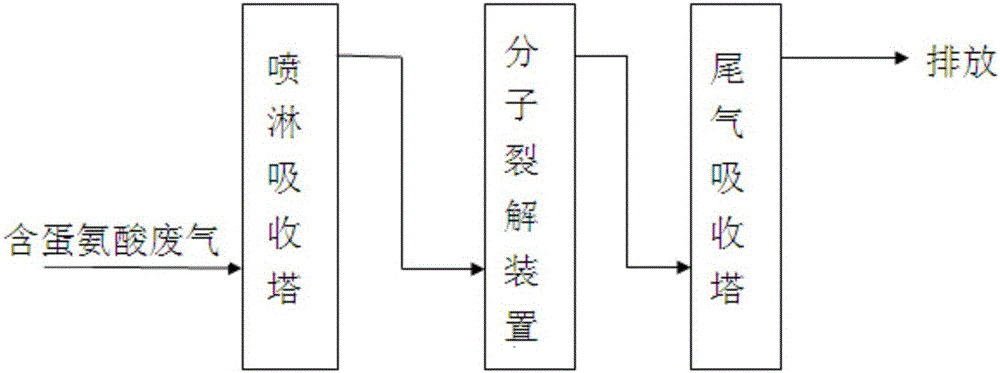

[0024] The waste gas from the methionine production process was treated according to the above method.

[0025] The concentration of methionine in the waste gas of methionine production process is about 45mg / m 3 , the wind volume is 100m 3 / h, the exhaust gas first passes through the pretreatment scrubber, the absorbent is water, and the spray density is 4m 3 / m 2 .h, the treated exhaust gas enters the molecular cracking system with a power of 3kw and a frequency of 500Hz. After the exhaust gas is degraded by the cracking reaction, it enters the exhaust gas absorption tower for advanced treatment. The absorbent is 5%wt NaOH aqueous solution, and the spray density is 8m 3 / m 2 .h, continue the above process, the effect of the device running for 1 hour is stable, and the removal rate of methionine reaches 96.1%.

Embodiment 2

[0027] The waste gas from the methionine production process was treated according to the above method. The main devices used in this embodiment include: a pretreatment absorption tower, a molecular cracking device, and a tail gas absorption tower.

[0028] The concentration of methionine in the waste gas of methionine production process is about 32mg / m 3 , the wind volume is 100m 3 / h, the exhaust gas first passes through the pretreatment scrubber, the absorbent is ethylene glycol, and the spray density is 8m 3 / m 2 .h, the treated exhaust gas enters the molecular cracking system with a power of 5kw and a frequency of 800Hz. After the exhaust gas is degraded by the cracking reaction, it enters the exhaust gas absorption tower for advanced treatment. The absorbent is 5%wt NaOH aqueous solution, and the spray density is 5m 3 / m 2 .h, continue the above process, the effect of the device running for 1 hour is stable, and the removal rate of methionine reaches 97.7%.

Embodiment 3

[0030] The waste gas from the methionine production process was treated according to the above method. The main devices used in this embodiment include: a pretreatment absorption tower, a molecular cracking device, and a tail gas absorption tower.

[0031] The concentration of methionine in the waste gas of methionine production process is about 49mg / m 3 , the wind volume is 100m 3 / h, the exhaust gas first passes through the pretreatment scrubber, the absorbent is water, and the spray density is 10m 3 / m 2 .h, the treated exhaust gas enters the molecular cracking system with a power of 10kw and a frequency of 1000Hz. After the exhaust gas is degraded by the cracking reaction, it enters the exhaust gas absorption tower for advanced treatment. The absorbent is 5%wt NaOH aqueous solution, and the spray density is 6m 3 / m 2 .h, continue the above process, the effect of the device operation is stable for 1 hour, and the removal rate of methionine reaches 98.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com