Preparation method of supported metal oxide catalyst for reinforcing ozonolysis and ozone catalytic ozonation catalyst prepared through preparation method

An ozone decomposition and oxide technology, applied in metal/metal oxide/metal hydroxide catalysts, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the secondary pollution of the environment, no research, Resource waste and other problems, to achieve the effect of low cost, speed up the reaction rate, and reduce operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

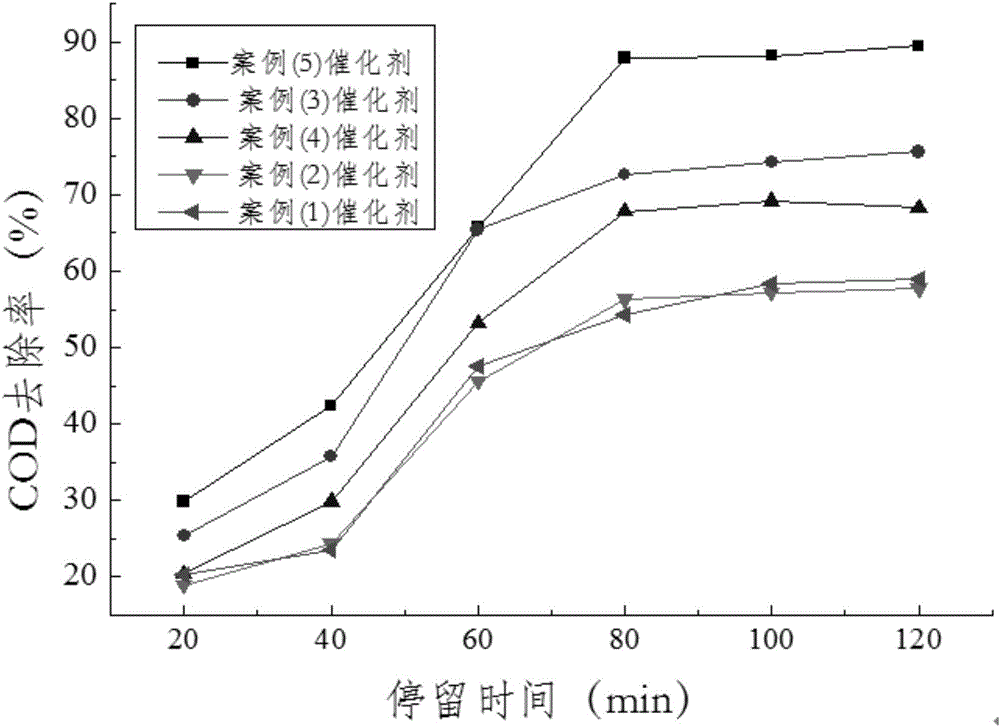

Examples

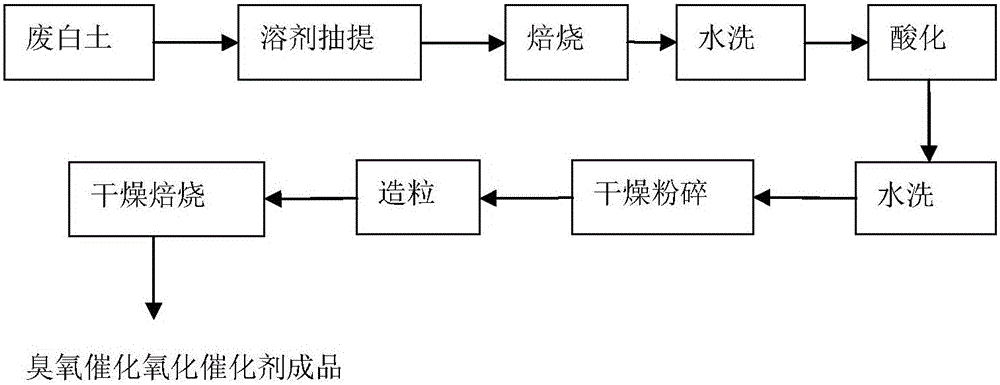

Embodiment 1

[0084] (1) Solvent extraction. Take 500 g of waste clay produced in an oil refinery, add gasoline and benzene in a mixed solvent with a volume ratio of 2:1, heat up to 40° C. while stirring, and have a reaction time of 20 minutes. After filtering, oil-free waste clay is obtained;

[0085] (2) Roasting. Put the oil-removed waste clay in a tube furnace at 400°C for 1 hour and roast it with air at a flow rate of 300mL / min;

[0086] (3) Wash with water. Take out the waste clay in step (2) and cool to room temperature and immerse in deionized water for 45 minutes;

[0087] (4) pickling. Dry the waste clay in step (3) at room temperature for 1 hour, put it into a sulfuric acid solution with a concentration of 2% according to the liquid-solid ratio of 1.1:1 (v / w), stir for 20 minutes, and heat up to 40°C, acidify Filter after 1 hour to obtain waste white clay after acidification.

[0088] (5) Wash with water. Wash the acidified waste clay with deionized water until the pH value...

Embodiment 2

[0093] The difference between this case and Case 1 during implementation is that the proportioning of each component in step (7) is as follows: the active component 10% (wherein mixed rare earth oxide 2%, Fe 2 o 3 4%, MnO 2 4%), recycled clay 37.9%, carbon black powder 2%, lime 0.1%, alumina powder 50%. Stir the above components evenly and put them into the granulator, and take them out when they roll to 3-4mm. The other steps are the same to obtain an ozone catalytic oxidation catalyst.

Embodiment 3

[0095] (1) Solvent extraction. Take 500 g of waste clay produced in an oil refinery, add gasoline and benzene in a mixed solvent with a volume ratio of 3:1, heat up to 80° C. while stirring, and have a reaction time of 60 minutes. After filtering, oil-free waste clay is obtained;

[0096] (2) Roasting. The oil-removed waste clay was roasted in a tube furnace at 800°C for 4 hours, and the air flow rate was 500mL / min;

[0097] (3) Wash with water. Take out the waste clay in step (2) and cool to room temperature and immerse in deionized water for 60 minutes;

[0098] (4) pickling. Dry the waste clay in step (3) at room temperature for 4 hours, put it into a sulfuric acid solution with a concentration of 10% according to the liquid-solid ratio of 3:1 (v / w), stir for 20 minutes, and heat up to 120°C, acidify After 5 hours, filter to obtain acidified waste white clay.

[0099] (5) Wash with water. Wash the acidified waste clay with deionized water until the pH value does not c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com