Fire-resistant, cold-resistant and sound-absorbing lightweight material for high-speed trains and preparation method

A technology for high-speed trains and lightweight materials, applied to chemical instruments and methods, vehicle parts, transportation and packaging, etc., to achieve low manufacturing costs, good noise reduction effects, and the effects of curbing heat convection conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1:10 and 90; Embodiment 2:15 and 85; Embodiment 3:20 and 80; Embodiment 4:12 and 88; Embodiment 5

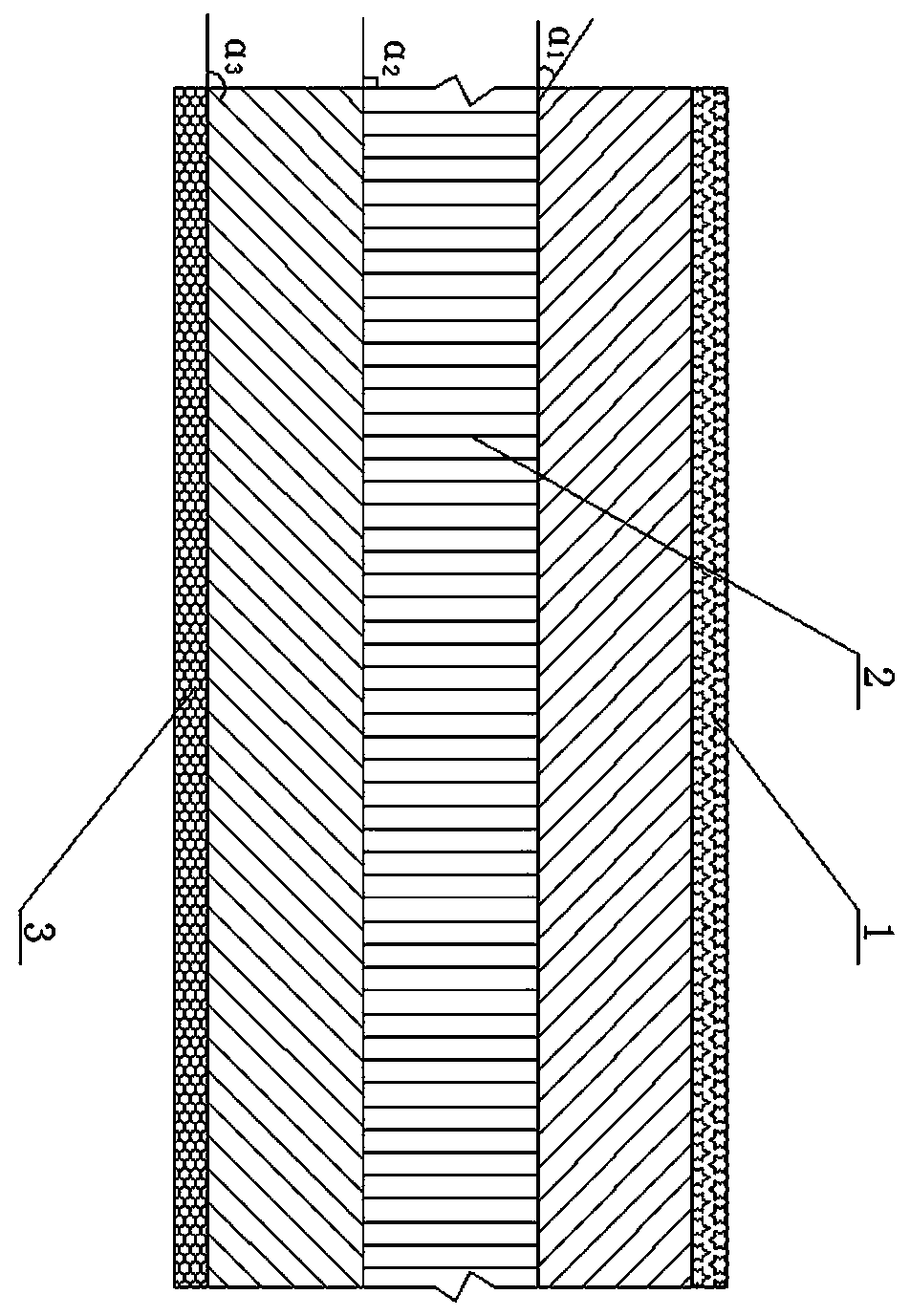

[0017] Composite fiber layer 2 is made up of the weight part raw material of following embodiment: Embodiment 1: 10 parts of polyester fiber and 90 parts of polyacrylonitrile preoxidized fiber; Embodiment 2: 15 parts of polyester fiber and polyacrylonitrile preoxidized fiber 85 parts; Embodiment 3: 20 parts of polyester fiber and 80 parts of polyacrylonitrile preoxidized fiber; Embodiment 4: 12 parts of polyester fiber and 88 parts of polyacrylonitrile preoxidized fiber; Embodiment 5: 17 parts of polyester fiber And 83 parts of polyacrylonitrile preoxidized fiber.

[0018] The preparation method of the fire-resistant, cold-resistant and sound-absorbing lightweight material for high-speed trains comprises the following steps: ① Mix 10-20 parts of polyester fiber and 80-90 parts of polyacrylonitrile pre-oxidized fiber, and comb to form a composite fiber net after mixing; ② Lay the composite fiber web obtained in step ① through a folding web-laying machine. The number of layers o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com