Membrane bioreactor and operating method thereof for enhanced membrane fouling control

A technology of membrane bioreactor and pollution control, applied in the direction of chemical instruments and methods, water treatment parameter control, sustainable biological treatment, etc., can solve problems such as complex operation, secondary pollution, difficult online cleaning, etc. The effect of increasing the amount, increasing the service life, and reducing the transmembrane pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

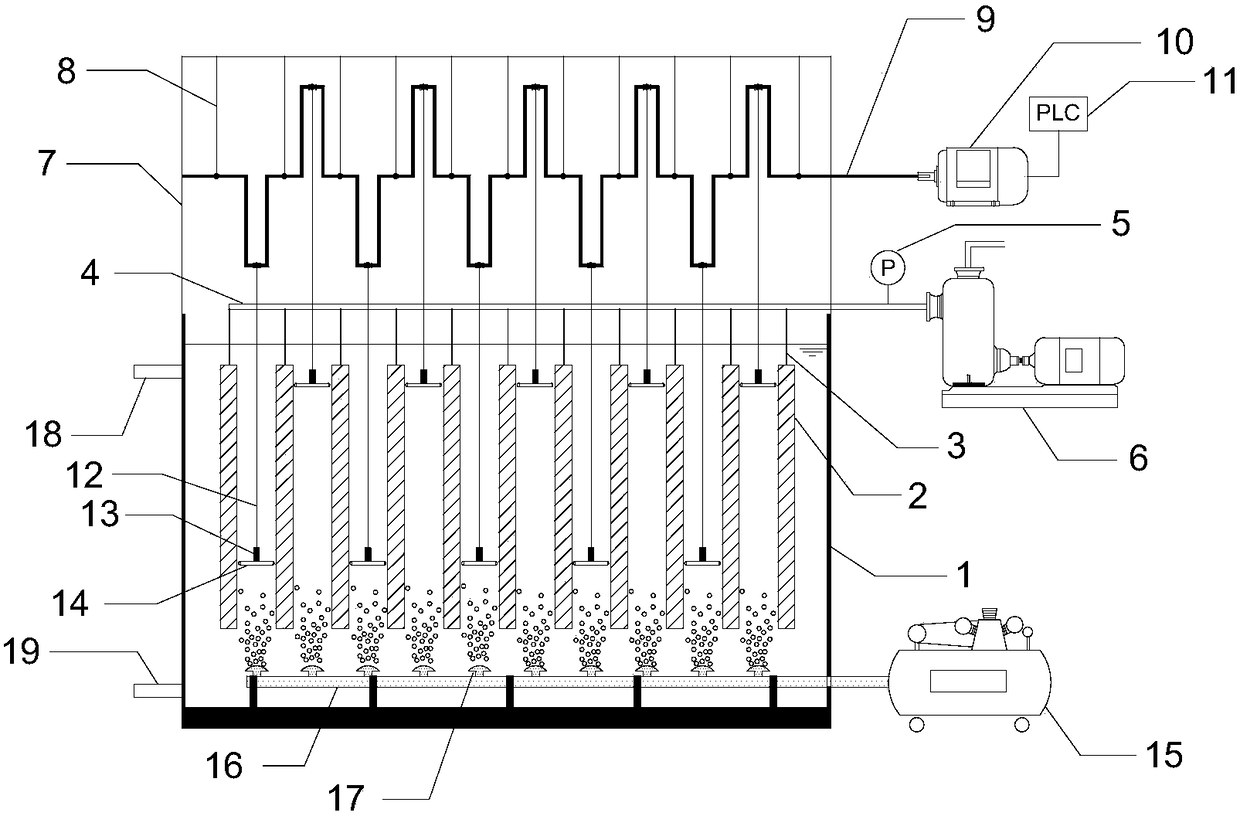

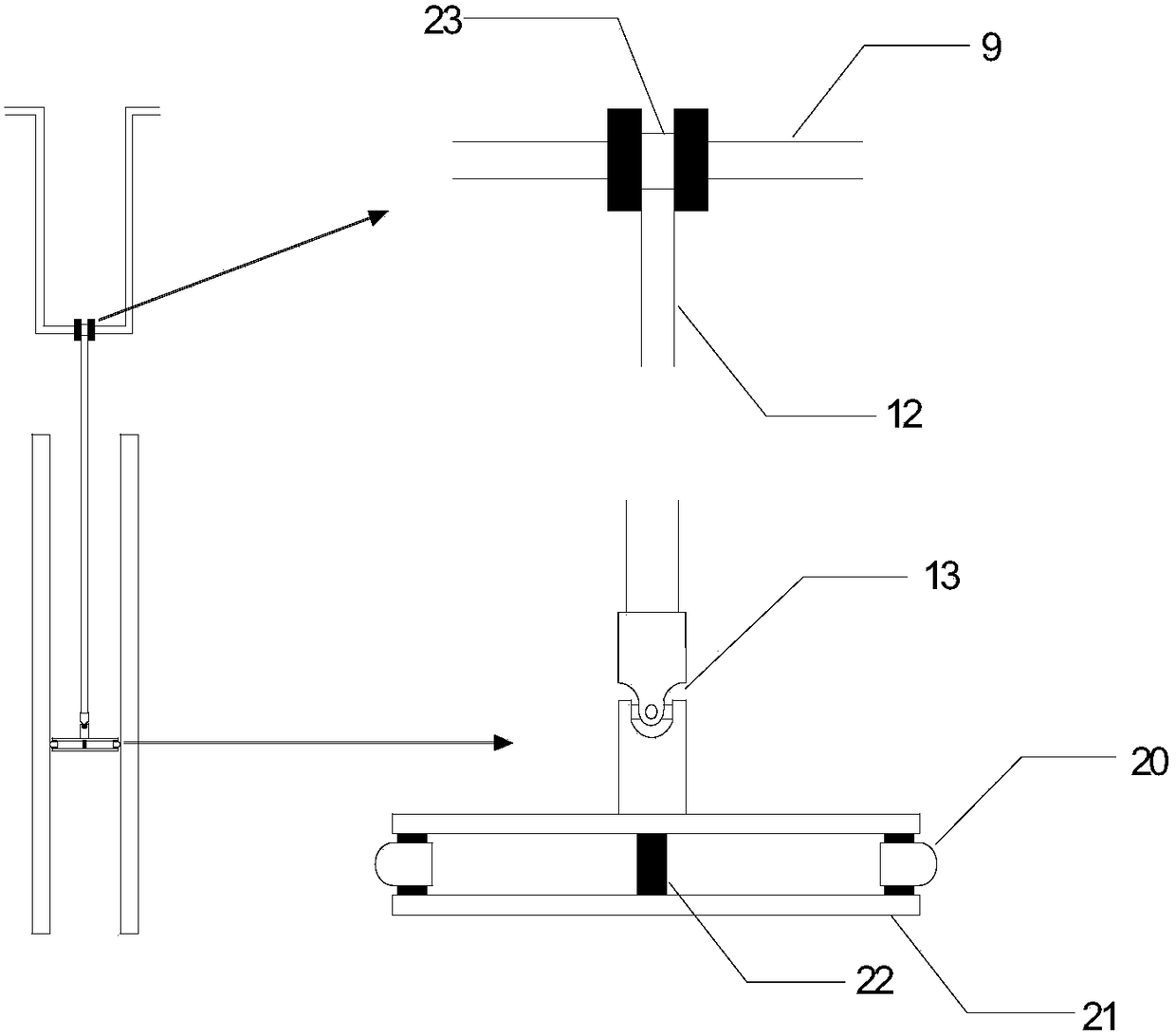

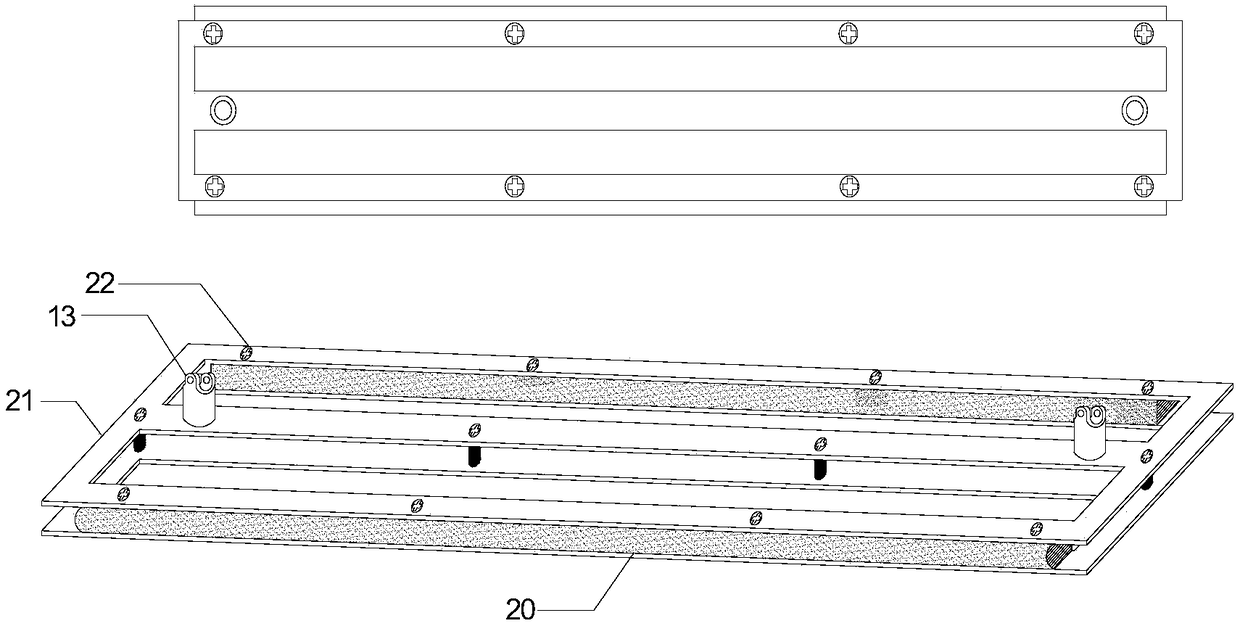

[0026] Such as figure 1 As shown, a membrane bioreactor for strengthening membrane pollution control includes reactor wall 1, membrane element 2, collecting pipe 3, water collecting pipe 4, vacuum gauge 5, suction pump 6, cleaning assembly, air compressor 15, Aeration pipe 16, aeration head 17, water inlet pipe 18 and mud discharge pipe 19; the cleaning assembly includes stainless steel frame 7, stainless steel boom 8, transmission shaft 9, motor 10, programmable logic controller 11, stainless steel connecting pipe 12. Universal joint 13, cleaning member 14, and air compressor 15, wherein the bottom of the stainless steel frame 7 is connected to the upper part of the reactor wall 1; the upper end of the stainless steel boom 8 is fixed on the top of the stainless steel frame 7, and the lower end of the stainless steel boom 8 It is connected with the transmission shaft 9 in the form of a suspension ring; one end of the transmission shaft 9 is connected to the motor 10, and the o...

Embodiment 2

[0034] The structure of the membrane bioreactor for strengthening membrane pollution control is the same as that of Example 1, except that the cleaning head 20 is made of PU collodion.

Embodiment 3

[0036] The structure of the membrane bioreactor for strengthening the control of membrane pollution is the same as that of Example 1, except that the cleaning head 20 is made of water-absorbing fiber gauze.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com