Method for preparing magnetic induction assembled colloidal photonic crystal with mini-emulsion polymerization method

A mini-emulsion polymerization and photonic crystal technology, which is applied in the field of functional photonic crystal materials to achieve the effects of mild reaction conditions, widened preparation routes and simple operation procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

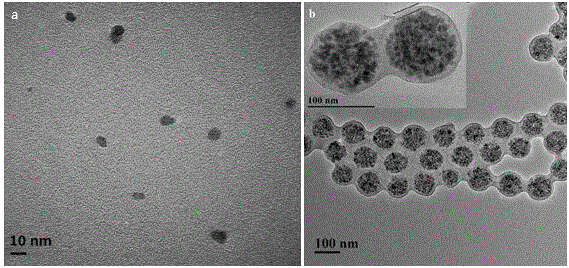

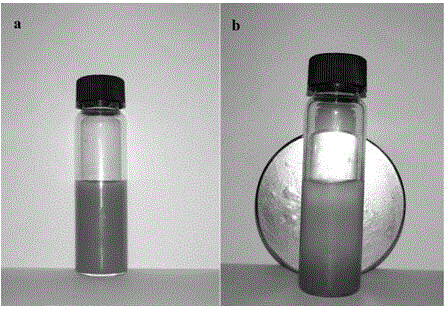

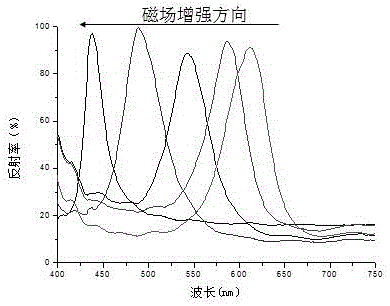

[0026] (1) Co-precipitation method to prepare oleic acid-modified ferric oxide magnetic nanoparticles: add 0.01mol ferric chloride and 0.01mol ferrous chloride to 150mL ultrapure water that has been treated with nitrogen gas to remove oxygen, and ultrasonically dissolve at 50-60KHz , to obtain a mixed solution. The resulting mixed solution was transferred to a 250 mL three-necked flask, and placed in a 60°C oil bath. Add 20 mL of ammonia water and 0.5 g of oleic acid in sequence, pass nitrogen to remove oxygen throughout the reaction, and react for 0.5 h. After the reaction, a magnet was placed at the bottom of the flask to absorb the particles. The collected particles were washed to neutral with deionized water, and dried in a vacuum oven at 40° C. to obtain oleic acid-modified ferroferric oxide magnetic nanoparticles.

[0027] (2) Preparation and assembly of polymer-coated magnetic nanoparticles:

[0028] a. Preparation of miniemulsion A: Weigh 0.5 g of oleic acid-modifie...

Embodiment 2

[0035] (1) Co-precipitation method to prepare oleic acid-modified iron ferric oxide magnetic nanoparticles: add 0.01mol ferric chloride and 0.01mol ferrous sulfate to 120mL ultrapure water that has been treated with nitrogen to remove oxygen, and ultrasonically dissolve at 50-60KHz. A mixed solution was obtained. The resulting mixed solution was transferred to a 250 mL three-necked flask, and placed in an oil bath at 100°C. Add 30 mL of ammonia water and 1 g of oleic acid in sequence, pass nitrogen to remove oxygen throughout the reaction, and react for 2 hours. After the reaction, a magnet was placed at the bottom of the flask to absorb the particles. The collected particles were washed with deionized water until neutral, and dried in a vacuum oven at 50° C. to obtain oleic acid-modified ferroferric oxide magnetic nanoparticles.

[0036] (2) Preparation and assembly of polymer-coated magnetic nanoparticles:

[0037] a. Preparation of miniemulsion A: Weigh 1 g of oleic acid...

Embodiment 3

[0042] (1) Co-precipitation method to prepare oleic acid-modified iron ferric oxide magnetic nanoparticles: add 0.01mol ferric chloride and 0.01mol ferrous sulfate to 90mL ultrapure water that has been treated with nitrogen to remove oxygen, and ultrasonically dissolve at 50-60KHz. A mixed solution was obtained. The resulting mixed solution was transferred to a 250 mL three-necked flask, and placed in an 80°C oil bath. Add 10 mL of ammonia water and 0.1 g of oleic acid in sequence, pass nitrogen to remove oxygen during the whole reaction, and react for 1 h. After the reaction, a magnet was placed at the bottom of the flask to absorb the particles. The collected particles were washed with deionized water until neutral, and dried in a vacuum oven at 45° C. to obtain oleic acid-modified ferroferric oxide magnetic nanoparticles.

[0043] (2) Preparation and assembly of polymer-coated magnetic nanoparticles:

[0044] a. Preparation of miniemulsion A: Weigh 0.1 g of oleic acid-mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com