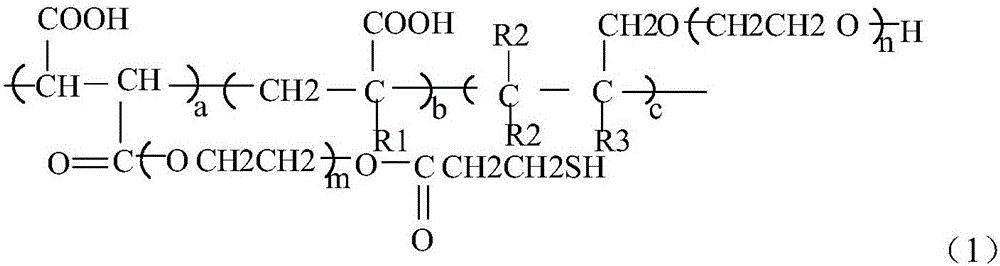

Water-reduction and plasticity-maintaining polycarboxylate-type water reducing agent and preparing method thereof

A polycarboxylic acid-based, water-reducing agent technology, applied in the field of cement dispersants, can solve the problems of plastic retention and concrete state and poor cohesion, divergence, easy segregation and bleeding, etc., and achieves excellent working performance, simplified technological process, Widely adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

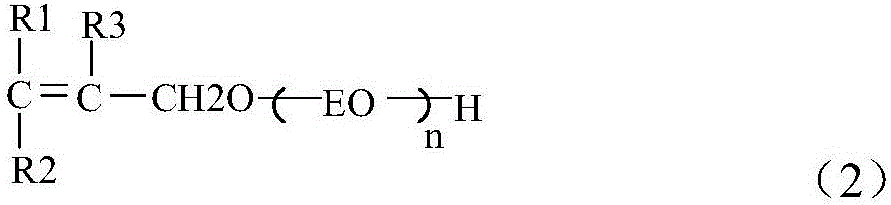

Method used

Image

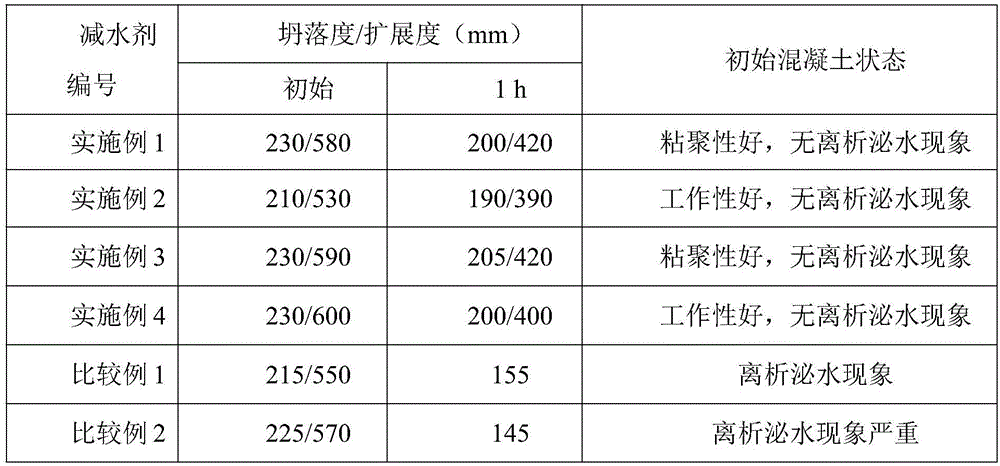

Examples

Synthetic example 1

[0038] Add 200g of PEG400 (0.5mol), SA53g (0.5mol), 0.6g of polymerization inhibitor hydroquinone, 6.0g of catalyst concentrated sulfuric acid and 27g of water-containing silica gel to a four-necked glass flask with thermometer, condenser and stirring device. , The temperature is slowly raised to 80°C. After the temperature rose to 80°C for 3.0 hours of reaction, 49g (0.5mol) of maleic anhydride was added to the reaction kettle, and the reaction was continued for 3.0 hours at this temperature. After the reaction is completed, the silica gel is filtered out to obtain about 270 g of sulfur group-containing modified monomer SA-PEG400-MAL.

Synthetic example 2

[0040] Add 300g of PEG600 (0.5mol), SA53g (0.5mol), 0.8g of polymerization inhibitor hydroquinone, 8.0g of catalyst concentrated sulfuric acid and 36g of water-containing silica gel to a four-necked glass flask equipped with a thermometer, condenser and stirring device. , The temperature is slowly raised to 90°C. After the temperature rose to 90°C for 4.0 hours, 49g (0.5mol) maleic anhydride was added to the reaction kettle, and the reaction was continued at this temperature for 2.0 hours. After the reaction is completed, the silica gel is filtered out to obtain about 370 g of sulfur-containing modified monomer SA-PEG600-MAL.

Embodiment 1

[0042] 100g of deionized water was added to a four-necked glass flask equipped with a thermometer, a condenser and a stirring device, the stirring was turned on, and 107g of HPEG23 (0.1 mol) was added to it, and the temperature was started. When the temperature rises to 60°C, add 0.25g FAS to the flask and stir for 15 minutes, and then start to feed A and B with a metering pump. Material A is 21.6gAA (0.3mol), 5.68g SA-PEG400-MAL (0.01mol) and 6.82g deionized water to form an 80% aqueous solution; material B is 0.52g initiator (NH 4 ) 2 S 2 O 8 Add 9.88g of deionized water to the solution to make a 5% mass fraction of aqueous solution. Material A was dropped in 2.5 hours, and material B was added in 3.0 hours. After the addition of material A, keep it at this temperature for 1.0h, reduce to about 40℃, neutralize with 30% NaOH to pH=6-8, and add quantitative water to obtain a mass fraction of 40% polycarboxylic acid reduction Liquid product 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com