Cable for high-voltage line

A high-voltage line and cable technology, applied in the direction of insulated cables, cables, power cables with shielding layers/conducting layers, etc., can solve problems such as affecting the transmission efficiency of cables, burning cables, easily causing leakage current, etc., and achieving excellent mechanical and physical properties. , Excellent flame retardant performance, no environmental pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

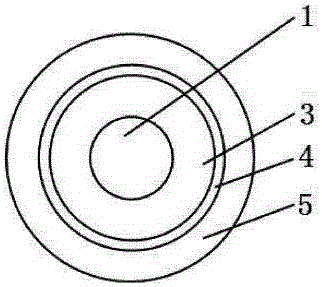

[0044] please see figure 1 , a cable for high-voltage lines, which includes a conductor 1, an insulating layer 3 coated outside the conductor by extrusion molding, a shielding layer 4 coated outside the insulating layer, and a sheath layer coated outside the shielding layer by extrusion 5, characterized in that the sheath layer is composed of the following raw materials in parts by weight: commercially available medium-density polyethylene or high-density polyethylene for wire and cable: 85 to 100 parts;

[0045] Ethylene-vinyl acetate copolymer: 10-20 parts;

[0046] Titanium dioxide with fineness less than 400 mesh: 5-8 parts;

[0047] Carbon black with a fineness of less than 400 mesh: 2 to 4 parts;

[0048] Aluminum hydroxide: 5-10 parts;

[0049] Titanium trioxide: 2 to 6 parts;

[0050] Antioxidant for cable sheathing material of commercially available model 1010 or 1076: 1 to 3 parts;

[0051] Polyethylene wax: 2 to 4 parts;

[0052] Fineness less than 400 mesh mi...

Embodiment 2

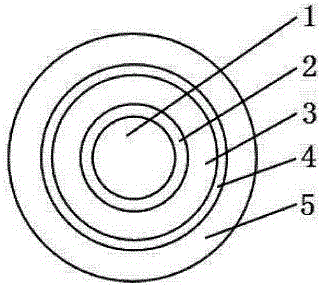

[0054] please see figure 2 , a cable for high-voltage lines, which includes a conductor 1, an inner shielding layer 2 coated outside the conductor, an insulating layer 3 coated outside the inner shielding layer by extrusion molding, a shielding layer 4 wrapped outside the insulating layer, and The sheath layer 5 is formed by extrusion coating outside the shielding layer, and it is characterized in that the sheath layer is composed of the following raw materials in parts by weight: commercially available medium-density polyethylene or high-density polyethylene for wire and cable: 85 ~100 copies;

[0055] Ethylene-vinyl acetate copolymer: 10-20 parts;

[0056] Titanium dioxide with fineness less than 400 mesh: 5-8 parts;

[0057] Carbon black with a fineness of less than 400 mesh: 2 to 4 parts;

[0058] Aluminum hydroxide: 5~10 parts;

[0059] Titanium trioxide: 2 to 6 parts;

[0060] Antioxidant for cable sheathing material of commercially available model 1010 or 1076: 1 ...

Embodiment 3

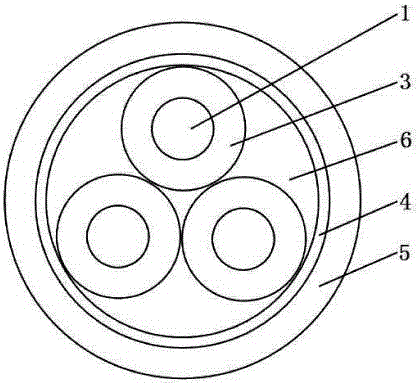

[0065] please see image 3 , a cable for high-voltage lines, including a cable core formed by placing three insulated conductors in a triangular cross section, a shielding layer 4 coated outside the cable core, and a sheath layer 5 coated outside the shielding layer by extrusion , the gap between the cable cores is filled with a filler 6 that prevents the movement of three insulated conductors, each insulated conductor includes a conductor 1 and an insulating layer 3 coated outside the conductor; it is characterized in that the sheath layer is calculated by weight, Consists of the following raw materials:

[0066] Commercially available medium-density polyethylene or high-density polyethylene for wire and cable: 85 to 100 parts;

[0067] Ethylene-vinyl acetate copolymer: 10-20 parts;

[0068] Titanium dioxide with fineness less than 400 mesh: 5-8 parts;

[0069] Carbon black with a fineness of less than 400 mesh: 2 to 4 parts;

[0070] Aluminum hydroxide: 5~10 parts;

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com