High-dielectric tunability ceramic/high polymer functional composite and preparation method

A functional composite material and tunable technology, applied in the field of information functional materials science, can solve problems such as dielectric tunability that is not involved, and achieve the effects of serialized dielectric constant, excellent dielectric properties, and good dielectric properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

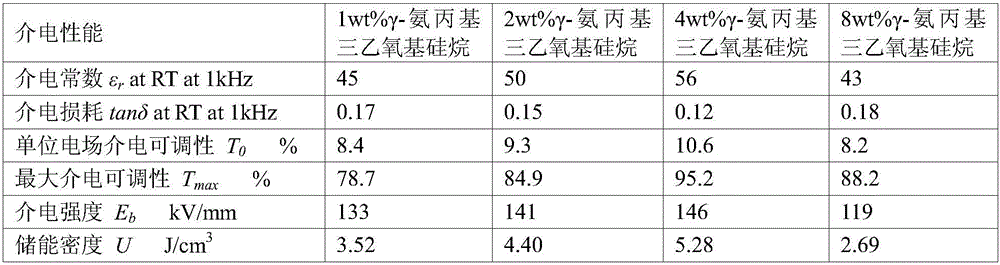

Embodiment 1

[0030] This embodiment is a dielectric functional composite material. The dielectric functional composite material is respectively using analytically pure barium carbonate, strontium carbonate, titanium dioxide, polyvinylidene fluoride and γ-aminopropyltriethoxysilane as starting materials, according to 40vol% barium strontium titanate +60vol% PVDF dosing. The atomic composition of the barium strontium titanate is Ba 0.6 Sr 0.4 TiO 3 , and the surface of the ceramic particle is modified by 1wt% of the weight of γ-aminopropyltriethoxysilane.

[0031] The specific process of preparing the dielectric functional composite material in this embodiment is:

[0032] In step 1, the analytically pure barium carbonate, strontium carbonate, and titanium dioxide powders are dosed according to the molar ratio of strontium-barium titanate, which is often used in the preparation of solid solution ceramics in the industry. The atomic composition of the barium strontium titanate is Ba 0.6...

Embodiment 2

[0040] This embodiment is a dielectric functional composite material. The dielectric functional composite material is respectively using analytically pure barium carbonate, strontium titanate, titanium dioxide, polyvinylidene fluoride and γ-aminopropyltriethoxysilane as starting materials, and is prepared by 40vol% strontium titanate The volume ratio batching of barium+60vol% polyvinylidene fluoride. The atomic composition of the barium strontium titanate is Ba 0.6 Sr 0.4 TiO 3 , and the surface of the ceramic particle is modified by 1wt% of the weight of γ-aminopropyltriethoxysilane.

[0041] The specific process of preparing the dielectric functional composite material in this embodiment is:

[0042] In step 1, the analytically pure barium carbonate, strontium titanate and titanium dioxide powders are mixed according to the molar ratio of strontium to barium titanate. The atomic composition of the barium strontium titanate is Ba 0.6 Sr 0.4 TiO 3 , and its preparation...

Embodiment 3

[0050] This embodiment is a dielectric functional composite material. The dielectric functional composite material is respectively using analytically pure barium carbonate, strontium titanate, titanium dioxide, polyvinylidene fluoride and γ-aminopropyltriethoxysilane as starting materials, and is prepared by 40vol% strontium titanate The volume ratio batching of barium+60vol% polyvinylidene fluoride. The atomic composition of the barium strontium titanate is Ba 0.6 Sr 0.4 TiO 3 , and the surface of the ceramic particle is modified by 1wt% of the weight of γ-aminopropyltriethoxysilane.

[0051] The specific process of preparing the dielectric functional composite material in this embodiment is:

[0052] In step 1, the analytically pure barium carbonate, strontium titanate and titanium dioxide powders are mixed according to the molar ratio of strontium to barium titanate. The atomic composition of the barium strontium titanate is Ba 0.6 Sr 0.4 TiO 3 , and its preparation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dielectric strength | aaaaa | aaaaa |

| Energy storage density | aaaaa | aaaaa |

| Dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com