External wall waterproof putty paste and preparation method thereof

A technology of putty paste and exterior wall, which is applied in the direction of filling slurry, etc., can solve the problems of poor practical application effect, peeling, mildew, and affecting the appearance, and achieve the effects of convenient construction, good water resistance, and scientific preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

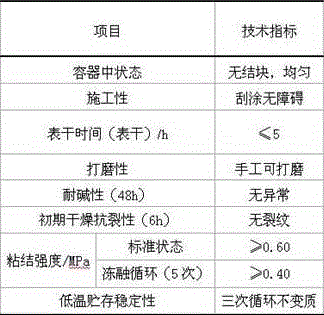

Image

Examples

Embodiment 1

[0022] Example 1 The exterior wall waterproof putty paste is mainly prepared from the following raw materials (5 kg each): 12 parts of polyvinyl acetate, 13 parts of soluble starch, 10 parts of sodium polyacrylate, 96 parts of heavy calcium carbonate, carboxymethyl 17 parts of sodium cellulose, 34 parts of talc, 9 parts of polypropylene fiber, 18 parts of attapulgite, 30 parts of deionized water, 1 part of preservative, and 0.5 part of dispersant. The preparation method of above-mentioned exterior wall waterproof putty paste is:

[0023] (1) Take heavy calcium carbonate and attapulgite and place them in a high-temperature environment to dry for 1 hour, take them out and grind them for 30 minutes to make a mixture powder, and the fineness of the mixture is controlled below 45 μm;

[0024] (2) Add deionized water to the mixer, add talc powder and dispersant, stir at high speed for 20 minutes, the stirring speed is 800 rpm, then add polyvinyl acetate, sodium polyacrylate, carboxy...

Embodiment 2

[0026] Example 2 The exterior wall waterproof putty paste is mainly prepared from the following raw materials (5 kg each): 16 parts of polyvinyl acetate, 18 parts of soluble starch, 15 parts of sodium polyacrylate, 104 parts of heavy calcium carbonate, carboxymethyl 23 parts of sodium cellulose, 42 parts of talc, 14 parts of polypropylene fiber, 22 parts of attapulgite, 50 parts of deionized water, 2 parts of preservative, and 1.5 parts of dispersant. The preparation method of above-mentioned exterior wall waterproof putty paste is:

[0027] (1) Take heavy calcium carbonate and attapulgite and place them in a high-temperature environment to dry for 3 hours, take them out and grind them for 46 minutes to make a mixture powder, and the fineness of the mixture is controlled below 45 μm;

[0028] (2) Add deionized water to the mixer, add talc powder and dispersant, stir at high speed for 40 minutes, the stirring speed is 1200 rpm, then add polyvinyl acetate, sodium polyacrylate, c...

Embodiment 3

[0030] Example 3 The exterior wall waterproof putty paste is mainly prepared from the following raw materials (5 kg each): 13 parts of polyvinyl acetate, 14 parts of soluble starch, 11 parts of sodium polyacrylate, 98 parts of heavy calcium carbonate, carboxymethyl 19 parts of sodium cellulose, 36 parts of talc, 10 parts of polypropylene fiber, 19 parts of attapulgite, 35 parts of deionized water, 1.2 parts of preservative, and 0.8 part of dispersant. The preparation method of above-mentioned exterior wall waterproof putty paste is:

[0031] (1) Take heavy calcium carbonate and attapulgite and place them in a high-temperature environment to dry for 1.5 hours, take them out and grind them for 34 minutes to make a mixture powder, and the fineness of the mixture is controlled below 45 μm;

[0032] (2) Add deionized water to the mixer, add talc powder and dispersant, stir at high speed for 25 minutes at a stirring speed of 900 rpm, then add polyvinyl acetate, sodium polyacrylate, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com