A method and system for recovering heavy hydrocarbons in liquefied natural gas production

A technology of liquefied natural gas and natural gas, which is applied in the direction of liquid hydrocarbon mixture recovery, hydrocarbon oil, gas fuel, etc., can solve the problems of increased process complexity, incomplete separation, and complicated process flow, so as to improve resource utilization efficiency and increase process efficiency. Effect of adding value and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

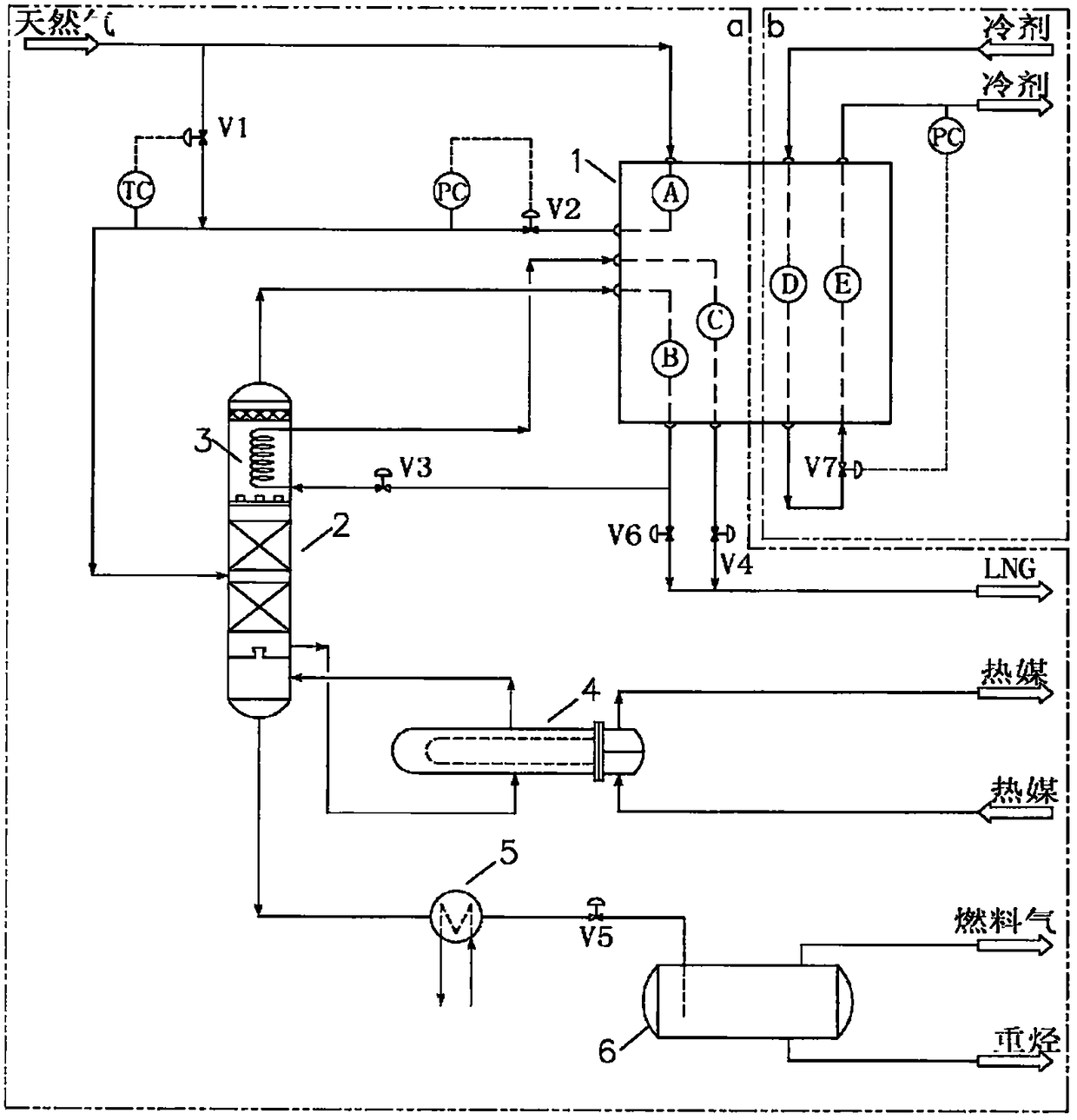

[0035] For the specific process flow of this embodiment, please refer to figure 1 .

[0036] A system for recovering heavy hydrocarbons in the production of liquefied natural gas, comprising: a first flow path A, a second flow path B, a third flow path C of a cold box 1, a heavy hydrocarbon removal tower 2, a tower top condenser 3, a bottom re- Boiler 4, heavy hydrocarbon cooler 5, heavy hydrocarbon storage tank 6, first valve V1 to sixth valve V6 and corresponding connecting pipelines, wherein, the inlet of the first flow channel A of the cold box 1 is connected with the raw gas pipeline, and the outlet passes through The second valve V2 is connected to the feed port of the heavy hydrocarbon removal tower 2; the inlet of the second channel B of the cold box 1 is connected to the shell-side gas phase outlet of the tower top condenser 3, and the outlet is connected to the LNG product pipeline through the sixth valve V6 ; The inlet of the third channel C of the cold box 1 is co...

Embodiment 2

[0039] For the specific process flow of this embodiment, please refer to figure 1 .

[0040] The raw natural gas I from the outside is passed into the inlet of the first channel A of the cold box 1. The raw natural gas is natural gas that has been deacidified, dehydrated, demercurized, and rich in heavy hydrocarbons, with a flow rate of 1500kg / h and a pressure of 6.5MPa , the temperature is 38°C, the total content of heavy hydrocarbons is 40ppmv, of which the content of neopentane is 10ppmv, the content of benzene is 10ppmv, and the content of C6 and above hydrocarbons is 20ppmv. After being cooled by the first channel A of the cold box 1, the temperature drops to -80 ℃ to obtain natural gas II in a gas-liquid two-phase state. The natural gas II is decompressed to 6.0 MPa through the second valve V2 and then enters the middle feed port of the heavy hydrocarbon removal tower 2. ℃, with a flow rate of 60.2kg / h of heavy hydrocarbons I, the gas phase outlet of the shell side of t...

Embodiment 3

[0042] For the specific process flow of this embodiment, please refer to figure 1 .

[0043] The raw natural gas I from the outside is passed into the inlet of the first channel A of the cold box 1. The raw natural gas is natural gas that has been deacidified, dehydrated, demercurized, and rich in heavy hydrocarbons, with a flow rate of 15000kg / h and a pressure of 3.5MPa , the temperature is 45°C, the total content of heavy hydrocarbons is 10000ppmv, of which the content of neopentane is 400ppmv, the content of benzene is 600ppmv, and the content of C6 and above hydrocarbons is 9000ppmv. After being cooled by the first channel A of the cold box 1, the temperature drops to -40 ℃ to obtain natural gas II in a gas-liquid two-phase state. The natural gas II is decompressed to 3.0 MPa through the second valve V2 and then enters the middle feed port of the heavy hydrocarbon removal tower 2, and is purified by rectification of the heavy hydrocarbon removal. ℃, with a flow rate of 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com