Method for preparing bean germination functional peptide

A technology of functional peptides and germination, which is applied in the field of preparation of germination functional peptides, can solve the problems that the technology of functional peptides has not yet appeared, and achieve the effects of low price, strong industrial implementation, and increased added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

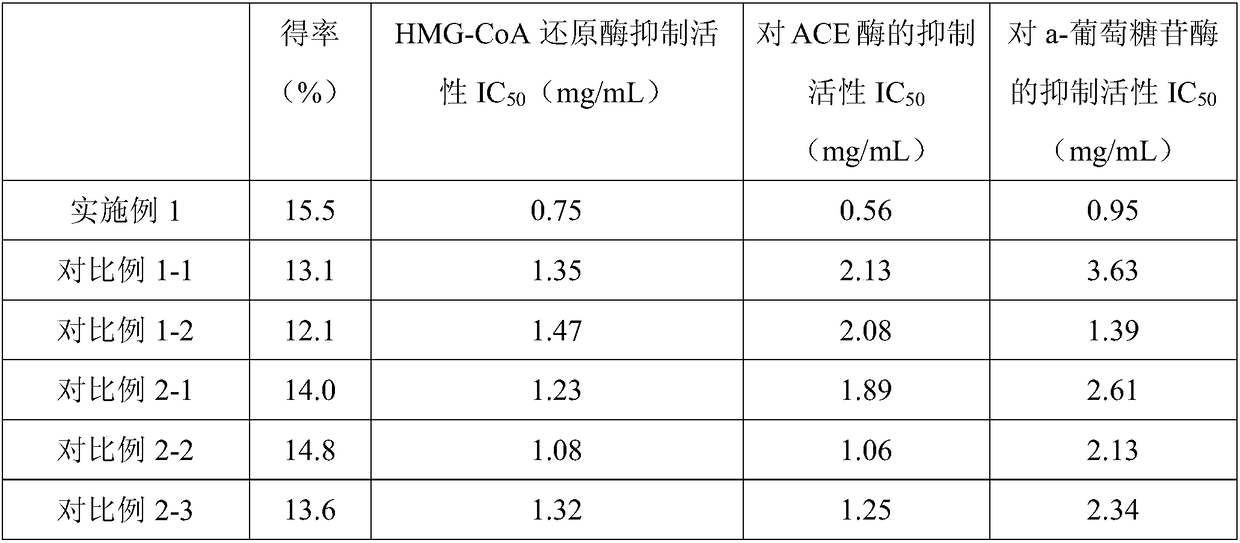

Examples

Embodiment 1

[0033] Embodiment 1, a kind of method for preparing soybean germination functional peptide, carries out following steps successively:

[0034] Germinate soybeans in a conventional manner, weigh 100 kg of germinated beans with a germination length of about 0.5 cm, add 100 kg of water to pulverize and make a slurry, stir evenly, adjust the pH value of the obtained slurry to 7.0, and then add neutral protease (500,000 u / g) 1kg, papain (3.5 million u / g) 1kg and compound flavor protease (1000LAPU / g) 1kg, enzymolysis reaction at 50℃~55℃ for 3h.

[0035] After the time is up, heat up the enzymolysis reaction product rapidly (heating rate is 10°C / min) to 90°C, and keep it warm for 10min; then rapidly cool down (cooling rate is 10°C / min) to room temperature to terminate the reaction; 6M large-capacity refrigerated centrifuge (BECKMAN company) centrifuged at 3000r / min at 4°C for 20min to obtain 150kg of supernatant, which was the enzymolysis solution (the enzymolysis solution contained...

Embodiment 2

[0038] Embodiment 2, a kind of method for preparing soybean germination functional peptide, carries out following steps successively:

[0039] Germinate soybeans in a conventional manner, weigh 200 kg of germinated beans with a germination length of about 0.5 cm, add 200 kg of water to pulverize and beat, stir evenly, adjust the pH value of the obtained slurry to 7.5, and then add neutral protease (500,000 u / g) 2kg, papain (3.5 million u / g) 2kg and compound flavor protease (1000LAPU / g) 2kg, enzymolysis reaction at 50℃~55℃ for 3h.

[0040] After the time is up, heat up the enzymolysis reaction product rapidly (heating rate is 10°C / min) to 90°C, and keep it warm for 10min; then rapidly cool down (cooling rate is 10°C / min) to room temperature to terminate the reaction; A 6M large-capacity refrigerated centrifuge (BECKMAN company) centrifuged at 3000r / min at 4°C for 20min, and the obtained supernatant was the enzymatic hydrolysis solution (the enzymolysis solution contains soybea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com