Feed protein detection method

A protein and feed technology, applied in the field of chemical detection, can solve the problems of unqualified sampling, inaccurate test results, and unscrupulous operation process, and achieve the effect of effective monitoring of protein content, accurate analysis data and fast analysis speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

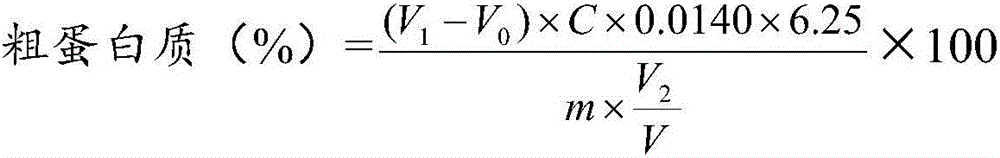

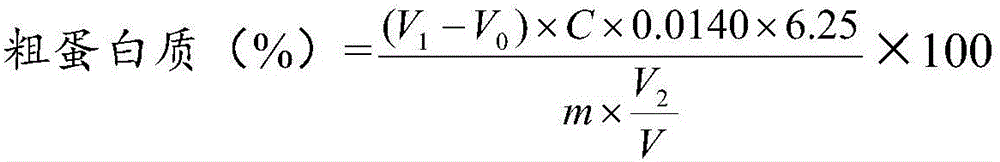

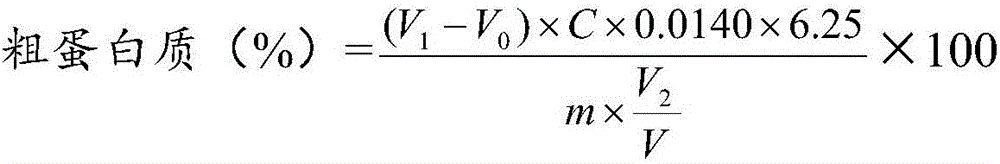

Image

Examples

Embodiment 1

[0030] 1. Instruments and equipment: the same as those used in the national standard "GB / T6432-1994" method.

[0031] 2. Reagents:

[0032] Mixed solution: Measure 100mL of distilled water and pour it into a beaker, slowly add 200mL of concentrated sulfuric acid, then add 300mL of 30% hydrogen peroxide after cooling, mix for later use.

[0033] Mixed catalyst: Weigh 10g of analytically pure copper sulfate, 100g of potassium sulfate, and 0.2g of selenium powder, put them into a mortar, grind them finely and pass through a 40-mesh sieve, mix well and set aside.

[0034] Other reagents are the same as those used in the national standard "GB / T6432-1994" method.

[0035] 3. Selection and preparation of samples: Select a representative sample and reduce it to 200g by quartering method. After crushing, all of them pass through a 40-mesh sieve and are placed in a sealed container to prevent changes in the composition of the sample.

[0036] 4. Analysis steps:

[0037] 4.1 Sample di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com