Rechargeable magnesium battery and preparation method thereof

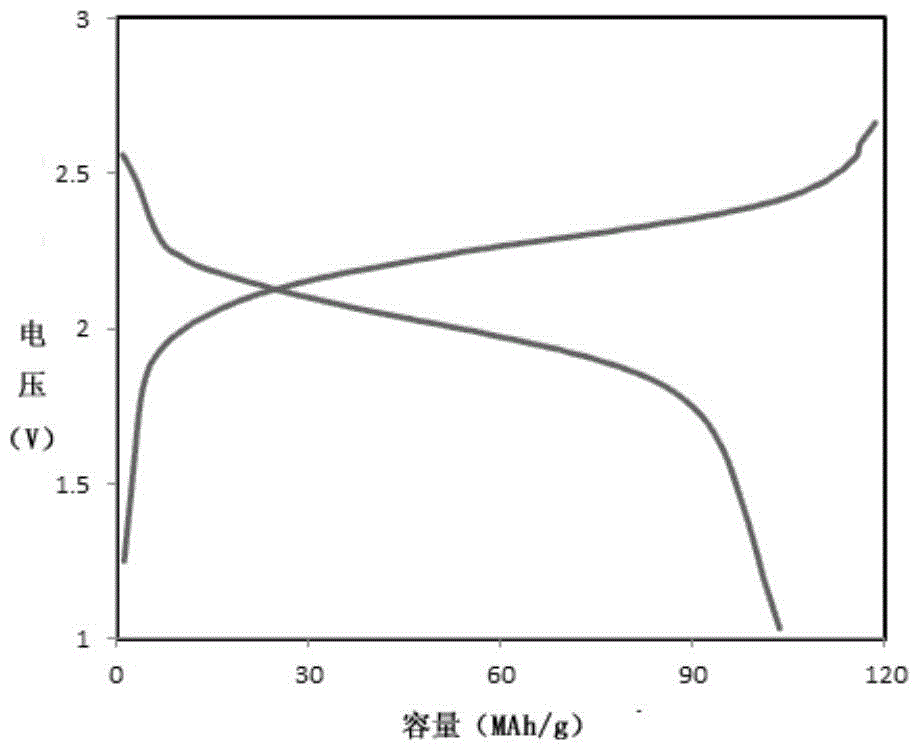

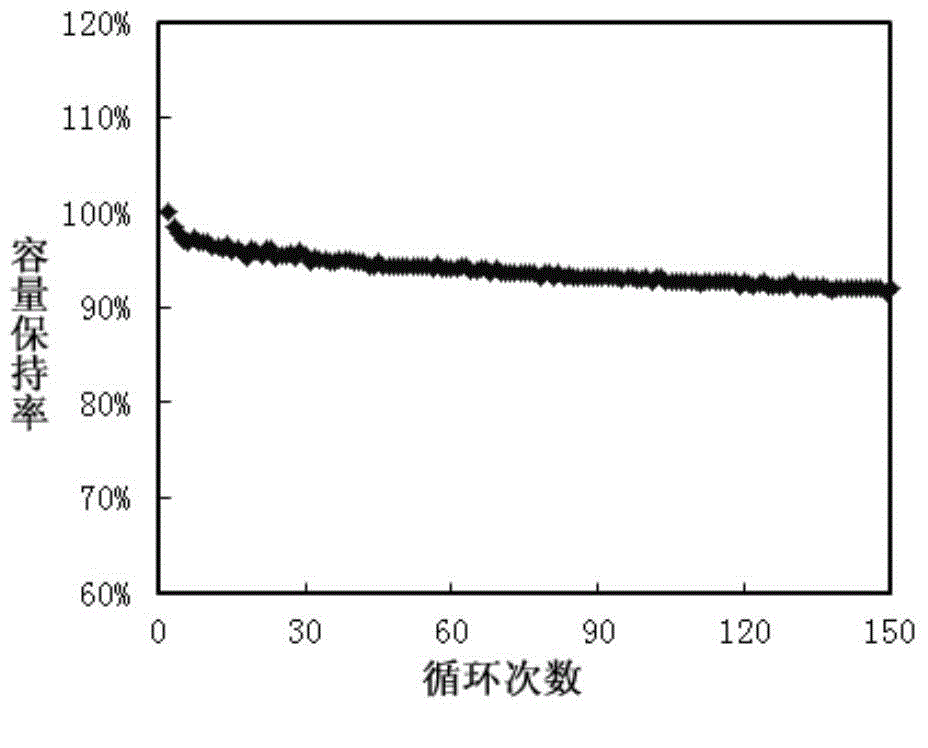

A magnesium battery and magnesium salt technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of harsh preparation conditions, low working platform voltage, and high cost, and achieve simple preparation methods, high energy density, and high working voltage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027]The method for preparing a rechargeable magnesium battery according to the second aspect of the present invention is used to prepare the rechargeable magnesium battery according to the first aspect of the present invention, comprising the steps of: (1) dissolving the transition metal salt in deionized water to form a first solution, Dissolving cyanide salt in deionized water to form a second solution, slowly adding the first solution dropwise to the second solution under magnetic stirring conditions, stirring, centrifuging, and drying, to obtain a Prussian blue compound with an open framework structure; ( 2) Add the positive electrode active material, positive electrode conductive agent, and positive electrode binder into the solvent according to a certain mass ratio, mix and stir evenly to make a positive electrode slurry, and then evenly coat the positive electrode slurry on the positive electrode current collector, and then dry, Cold pressing and cutting into pieces to...

Embodiment 1

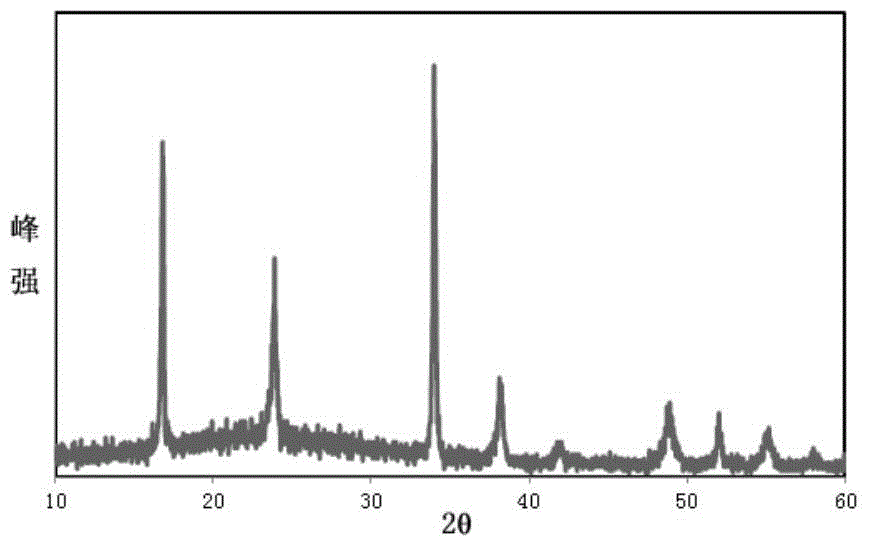

[0030] (1) 2.3g of transition metal salt Mn(NO 3 ) 2 Dissolved in 50ml deionized water to form the first solution, 1.42g of cyanide salt Na 4 Fe(CN) 6 10H 2 O and 14gNaCl were dissolved in 100ml deionized water to form the second solution. Slowly add the first solution dropwise to the second solution under magnetic stirring at 70°C and continue to stir for 2h, then centrifuge and wash with deionized water three times. A white precipitate is obtained, and then the white precipitate is dried at 120°C for 8 hours to obtain the Prussian blue compound Na 2 MnFe(CN) 6 ;

[0031] (2) The positive electrode active material Na 2 MnFe(CN) 6 , positive electrode conductive agent Super-P, positive electrode binder PVDF (PVDF is pre-dissolved in NMP to make a concentration of 0.02gmL -1 solution) was placed in a small beaker at a mass ratio of 8:1:1, and then magnetically stirred for 4 hours to obtain a uniformly mixed positive electrode slurry, and then the positive electrode slur...

Embodiment 2

[0036] Prepare a rechargeable magnesium battery according to the method of Example 1, except for the following differences:

[0037] (4) The magnesium salt is BR 3 -(PhMgCl) 2 , R represents 3,5-xylyl.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com