Experimental device for generating cavitation bubbles based on electric spark

An experimental device and cavitation bubble technology, which is applied to pressure vessels used in chemical processes, pressure vessels/vacuum vessels, etc., can solve problems such as low device safety, connection interference, and potential safety hazards, so as to simplify test operations and avoid short circuits Dangerous, mechanical strength enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

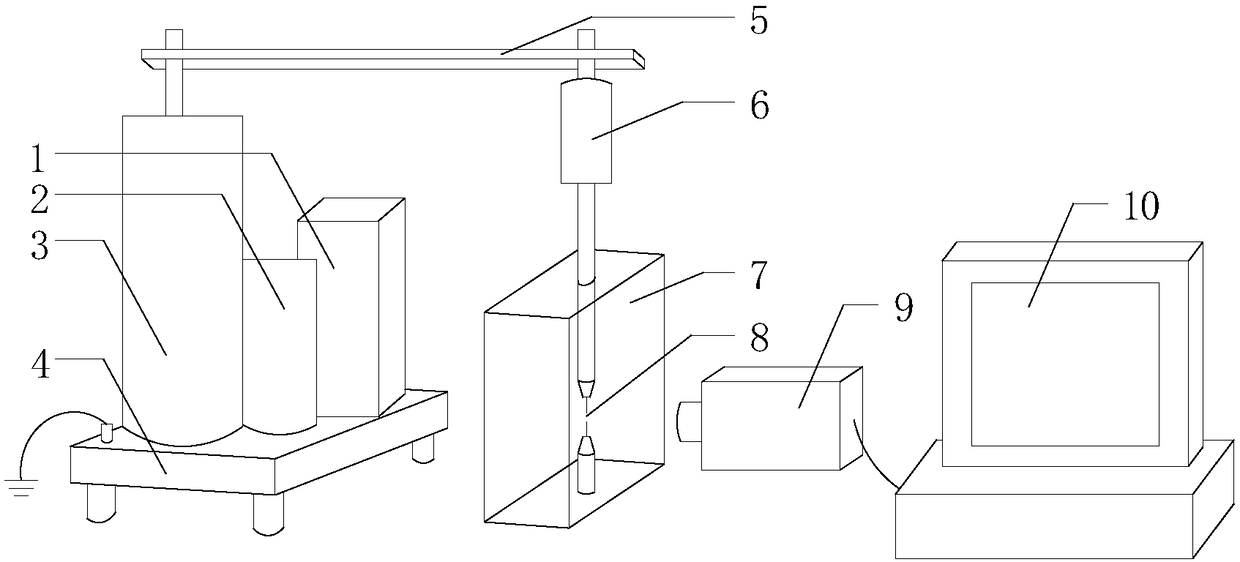

[0041] In this embodiment, the civilian 220V alternating current is selected as the power supply for the whole device, and the high leakage reactance test transformer 1, the high-speed camera 9, and the computer system 10 are connected respectively; distance from the magnifying lens; the computer system 10 is preinstalled with image processing software, and its image processing software is PFV3.6.4.

[0042] The specific values of the output four-level voltage of the high leakage reactance test transformer 1 are 15.76kV, 18.2kV, 21.4kV, and 25.6kV respectively; The rectification device 2 can obtain four sets of DC high voltage voltages of 19.7kV, 23.0kV, 27.5kV and 33kV.

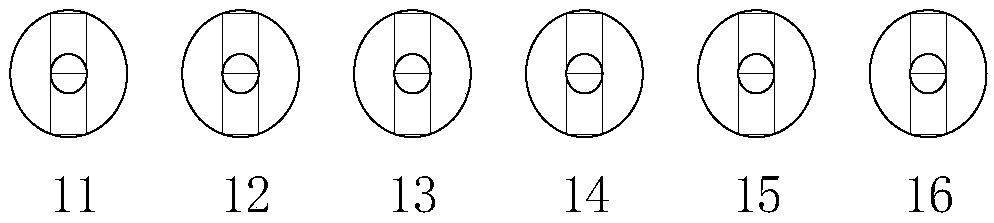

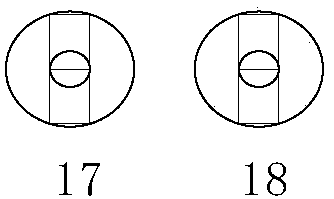

[0043] The five resistance values of the resistance bridge 5 are as follows: the first tap 19 of the resistance is 400 Ω, the second tap 20 of the resistance is 500 Ω, the third tap 21 of the resistance is 600 Ω, the fourth tap 22 of the resistance is 700 Ω and the fifth tap 23 of the resistance is 800Ω...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com