A method for preparing capsules from oil-soluble etherified amino resin

An etherified amino resin and oil-soluble technology is applied in the field of preparing capsules from oil-soluble etherified amino resin as a wall-forming raw material, which can solve the problems affecting the encapsulation effect and efficiency, poor encapsulation effect and efficiency, etc., and achieves good appearance. , the effect of high encapsulation efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Stir 10g of n-dodecyl alcohol and 10g of methyl etherified amino resin evenly to obtain an oil phase solution; add this oil phase solution to 200g of PVA aqueous solution with a concentration of 5wt%, and then emulsify at a high speed at 8000rpm for 15 minutes to obtain Stable oil-in-water emulsion; transfer the above-mentioned oil-in-water emulsion to a three-necked flask, and heat up to 70°C while stirring at a speed of 100rpm. During this process, adjust the pH value to about 4.5 with 10% citric acid solution, and react After 3 hours, the amino resin polymer capsule suspension can be obtained, and the capsule wet cake can be obtained after filtering, washing and drying.

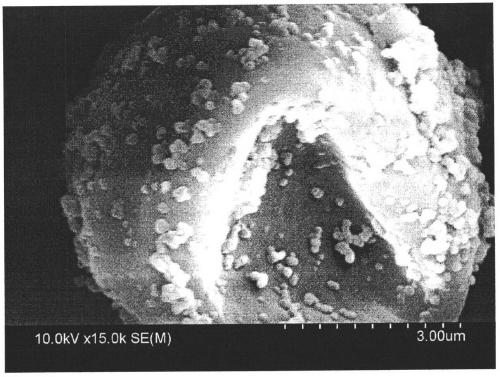

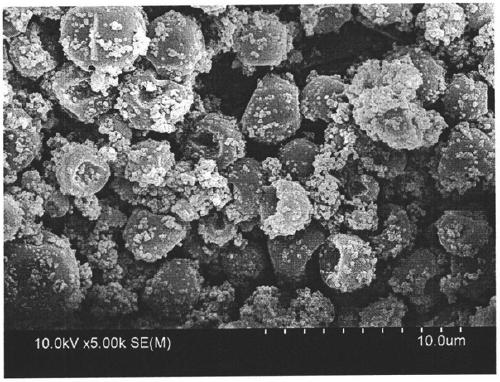

[0025] The amino resin polymer capsule that present embodiment makes is as figure 1 , 2 shown, from figure 1 It can be seen that nanoparticles are adhered to the surface of the capsule prepared in this example, the surface structure of the capsule is dense, and the capsule has certain depressions....

Embodiment 2

[0027] Stir 1 kg of cypress essential oil and 200 g of butylated amino resin evenly to obtain an oil phase solution; add this oil phase solution to 3 kg of a 5 wt % sodium polyacrylate aqueous solution, and then emulsify at a high speed at 10,000 rpm for 10 minutes to prepare A stable oil-in-water emulsion was obtained. Heat the above oil-in-water emulsion to 50°C while stirring at a speed of 200rpm. During this process, use 10% citric acid solution to adjust the pH value to about 3.5. After 3 hours of reaction, the suspension of amino resin polymer essence capsules can be obtained. solution, filtered, washed, and dried to obtain a capsule wet cake. Observing the sample with a scanning electron microscope, the particle size distribution of the prepared spherical capsules is 1-10 μm. The forming process of the capsule is simple and easy to control, and at the same time, the encapsulation efficiency is very high, and the industrialization prospect is very bright.

Embodiment 3

[0029] Mix 20kg of mosquito repellent incense oil, 5kg of dodecyl etherified amino resin and 1kg of acetone to obtain an oil phase solution; add this oil phase solution to a solution prepared by dissolving 10kg of styrene maleic anhydride sodium salt in 100kg of water In the emulsifier aqueous solution, emulsify at a high speed for 30 minutes under the condition of 2000rpm to obtain an oil-in-water emulsion with an average particle size of 20μm. Add acetic acid dropwise to adjust the pH value to 3, then raise the temperature to 85° C., and react for 2 hours to obtain the amino resin capsule suspension of mosquito repellent essence. The morphology and structure of the samples were observed with a scanning electron microscope, and the particle size of the spherical capsules was mostly distributed in the range of 5-80 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com