Method for preparing molecularly imprinted monolithic column

A technology of molecular imprinting and monolithic column, which is applied in the field of molecular imprinting chromatography, can solve problems such as insoluble, expensive, and interference in the determination of trace analytes, and achieve good imprinting effect and high recognition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

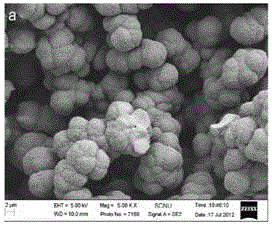

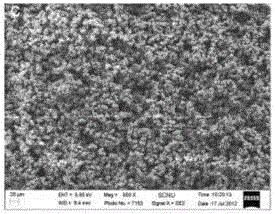

Image

Examples

Embodiment 1

[0029] A method for preparing a molecularly imprinted monolithic column, the preparation steps are as follows:

[0030] A, choose 1.5mmol methacrylic acid as functional monomer, 0.125mmol sulfamethoxazole (SMO) as false template molecule, 13.5mmol ethylene glycol dimethacrylate as cross-linking agent, false template molecule, functional monomer Add the cross-linking agent to the porogen solution of dimethyl sulfoxide (DMSO)-n-dodecyl alcohol system / water, mix and stir, and ultrasonically induce solubilization for 5 minutes to form a mixed solution of imprinted molecules and functional monomers;

[0031] B, the above-mentioned mixed solution-made is deoxygenated by nitrogen, and the nitrogen time is 10 minutes;

[0032] C, add 23.8mg initiator azobisisobutyronitrile in mixed solution one after logical nitrogen deoxygenation, make mixed solution two;

[0033] D. Pour the mixed solution II into a 100mm×4.6mm stainless steel chromatographic column tube I and seal it, and react in...

Embodiment 2

[0038] A method for preparing a molecularly imprinted monolithic column, the preparation steps are as follows:

[0039] A, choose 1.32mmol methacrylic acid as functional monomer, 0.12mmol sulfamethoxazole (SMO) as pseudo-template molecule, 12.0mmol ethylene glycol dimethacrylate as cross-linking agent, the pseudo-template molecule, functional monomer Add the cross-linking agent to the porogen solution of dimethyl sulfoxide (DMSO)-n-dodecyl alcohol system / water, mix and stir, and ultrasonically induce solubilization for 5 minutes to form a mixed solution 1 of imprinted molecules and functional monomers;

[0040] B, the above-mentioned mixed solution-made is deoxygenated by nitrogen, and the nitrogen time is 10 minutes;

[0041] C, add 23.8mg initiator azobisisobutyronitrile in the mixed solution one after nitrogen deoxygenation, make the mixed solution two;

[0042] D. Pour the mixed solution 2 into the 100mm×4.6mm stainless steel chromatographic column tube 1 and seal it insi...

Embodiment 3

[0049] A method for preparing a molecularly imprinted monolithic column, the preparation steps are as follows:

[0050] A, choose 1.3mmol methacrylic acid as functional monomer, 0.13mmol sulfamethoxazole (SMO) as pseudo-template molecule, 13.65mmol ethylene glycol dimethacrylate as cross-linking agent, make pseudo-template molecule, functional monomer Add the cross-linking agent and dimethyl sulfoxide (DMSO)-n-dodecyl alcohol system / water porogen solution, mix and stir, and ultrasonically induce solubilization for 10 minutes to form a mixed solution 1 of imprinted molecules and functional monomers;

[0051] B, the above-mentioned mixed solution-made is deoxygenated by nitrogen, and the nitrogen time is 10 minutes;

[0052] C, add 23.8mg initiator azobisisobutyronitrile in the mixed solution one after nitrogen deoxygenation, make the mixed solution two;

[0053] D. Pour the mixed solution II into a 100mm×4.6mm stainless steel chromatographic column tube I and seal it, and reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com