A water treatment method based on manganese-cobalt composite oxide nanoparticles modified ceramic membrane

A nanoparticle modification and composite oxide technology, which is applied in the fields of oxidized water/sewage treatment, permeate/dialysis water/sewage treatment, etc., can solve the problems such as impossibility to reduce the permeate flow and separation characteristics, pollution and blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0030] The method for assembling the catalytic ceramic membrane modified by manganese-cobalt composite oxide nanoparticles will be described below in conjunction with specific embodiments, so as to further understand the invention. The technical solution of the present invention is not limited to the specific embodiments listed below, but also includes any combination of the specific embodiments.

specific Embodiment approach 1

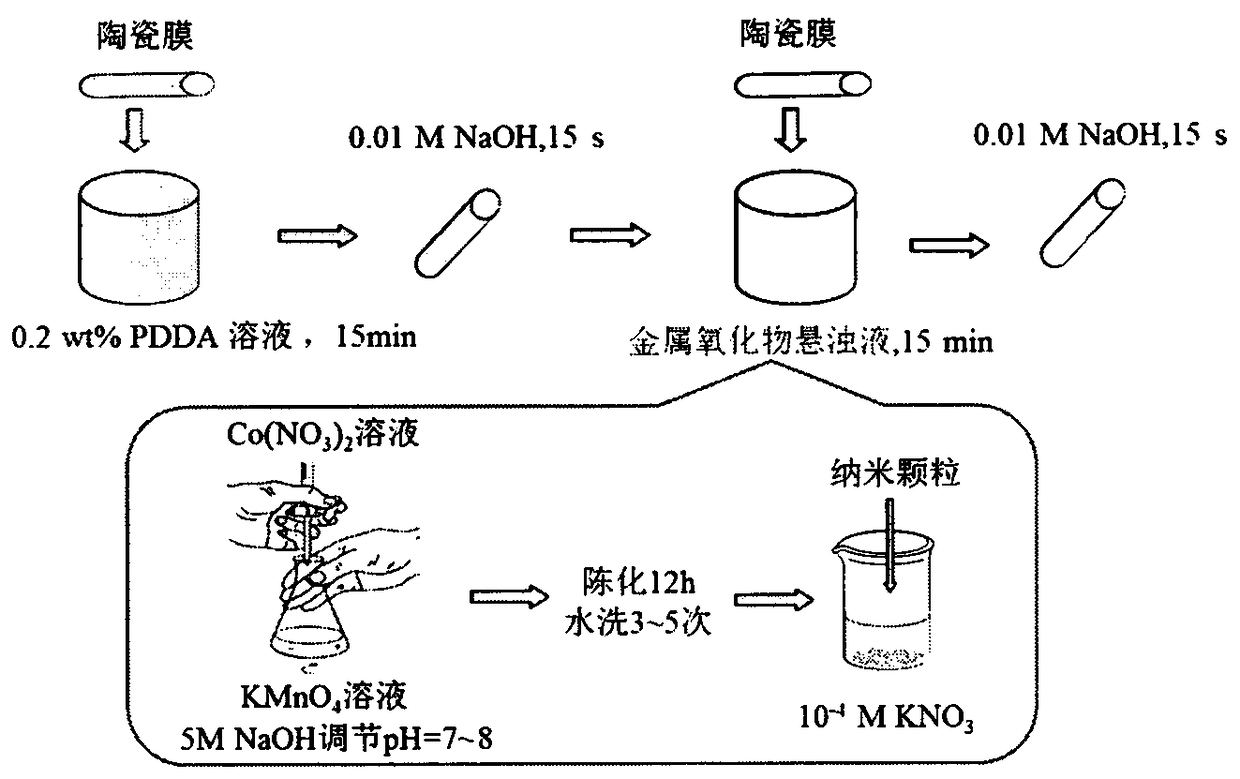

[0031] Specific implementation mode one: MnO 2 -Co 3 o 4 The assembly method of the nanoparticle-modified catalytic ceramic membrane can be realized through the following steps:

[0032] (1) Accurately weigh 13.0973g Co(NO 3 ) 2 ·6H 2 O and 2.3706 g KMnO 4 , were completely dissolved in 200mL of deionized water, so that the solute was completely dissolved to obtain a clear solution;

[0033] (2) Co(NO 3 ) 2 Add the solution dropwise to the KMnO at a rate of 2-3 drops per second 4 In the solution, use 5mol / L NaOH at the same time to adjust the pH of the mixed solution to 7-8, while the mixed solution is continuously stirred at 800rpm / min to obtain a homogeneous suspension;

[0034] (3) to be Co(NO 3 ) 2 After the solution was added dropwise, the mixed solution continued to stir for 1 h to ensure that the reaction was carried out completely;

[0035] (4) Aging the suspension for 12 hours at room temperature;

[0036] (5) Wash and age the obtained solid with deionize...

specific Embodiment approach 2

[0043] Specific embodiment two: the difference between this embodiment and specific embodiment one is that 13.0973g (45mmmol) Co(NO 3 ) 2 ·6H 2 O can be replaced by 10.7069g CoCl 2 ·6H 2 O, other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com