Application of Sodium Peroxosulfate

A technology of sodium peroxosulfate and sodium sulfate, which is applied in the field of water pollution treatment, can solve the problems of low decomposition rate and achieve the effects of simple operation, cost saving and improvement of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

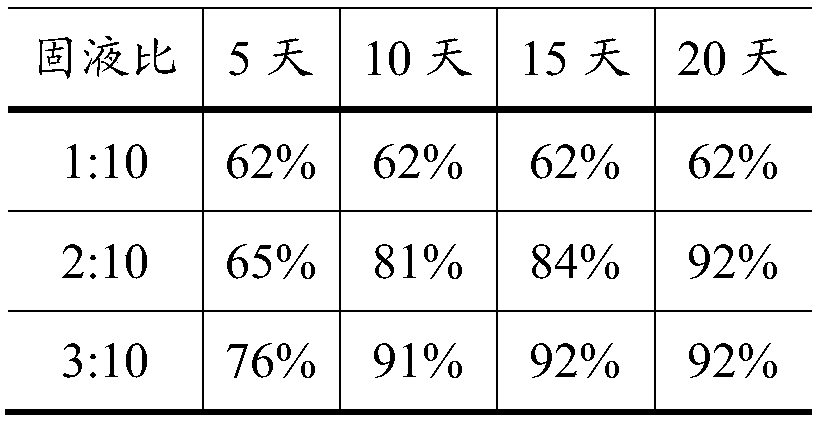

[0019] The waste water sample of the lake was taken, and its COD concentration was 7240mg / L, pH=7.3. The EHP and wastewater samples were mixed according to the solid-to-liquid ratio of 1:10, 2:10, and 3:10 (g / mL) respectively, and the EHP was fully dissolved.

[0020] After reacting for 5, 10, 15, and 20 days at a room temperature of 20±2°C, the COD concentration of each wastewater sample was measured and the degradation rate was calculated. The analysis results are shown in Table 1.

[0021] The COD degradation rate of table 1 embodiment 1 waste water

[0022]

[0023] The results of Example 1 show that COD is 7240mg / L waste water after 15-20 days of degradation, the degradation rate of COD reaches 92%, and the maximum degradation rate can be reached when the solid-liquid ratio is 2:10, when the solid-liquid ratio is 1:10 When the waste water COD degradation rate is only 63%.

Embodiment 2

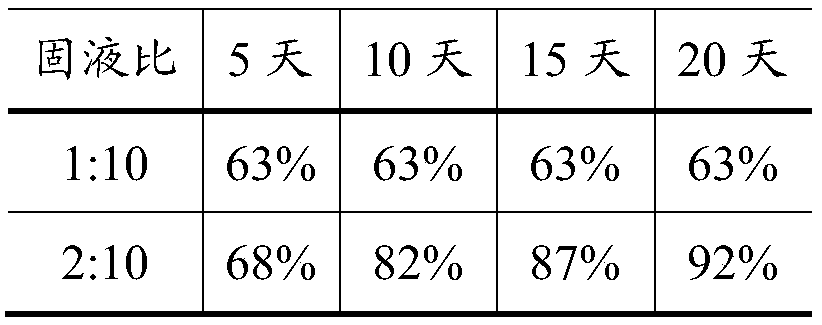

[0025] The waste water sample of the lake was taken, and its COD concentration was 7240mg / L, pH=7.3. Regulate the pH of waste water with the sulfuric acid of 1mol / L to be 3, add ferrous sulfate heptahydrate, make ferrous ion content in waste water be 0.5mmol / L, EHP and waste water sample are respectively 1:10, 2:1 by solid-liquid ratio 10 (g / mL) mixed, and completely dissolved EHP. After carrying out the control test according to Example 1, the COD concentration of each wastewater sample was measured respectively and the degradation rate was calculated. The analysis results are shown in Table 2.

[0026] The COD degradation rate of table 2 embodiment 2 waste water

[0027]

[0028] The results of Example 2 show that EHP can directly degrade the COD of polluted wastewater under a neutral pH. Compared with Example 1, the degradation rate of COD is basically the same, and there is no need to add a ferrous ion catalyst, which reduces operating steps and costs.

Embodiment 3

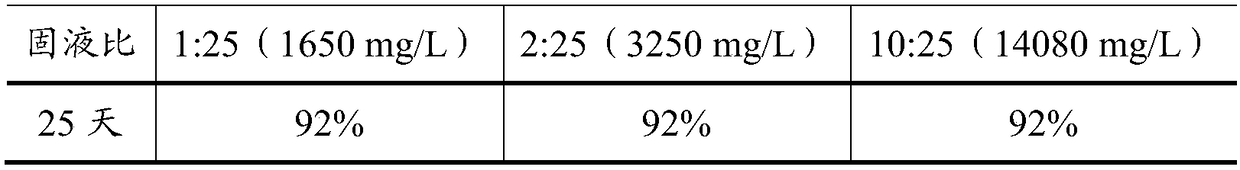

[0030] Take the wastewater samples from the lake, the wastewater COD concentrations are 1650mg / L, 3250mg / L, 14080mg / L, pH=7.3, and the degradation reaction is carried out. The EHP and wastewater samples were mixed according to the solid-liquid ratio of 1:25 (1650mg / L), 2:25 (3250mg / L), 10:25 (14080mg / L) (g / mL), that is, the peroxide in EHP The initial concentration of COD and wastewater COD concentration is about 5:2 (mg / L). Carry out the test according to Example 1, after reacting for 25 days, measure the COD concentration of each wastewater sample respectively and calculate the degradation rate, and the analysis results are shown in Table 3.

[0031] The COD degradation rate of table 3 embodiment 3 waste water

[0032]

[0033] Example 3 results show that when the initial concentration of peroxide radical in the EHP and the waste water COD concentration are about 5:2 (g / L), the waste water degradation rate can reach 92%, therefore, although the initial concentration of E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com