Circulating cooling water bypass flow water treatment system and bypass flow water treatment method

A technology of circulating cooling water and flowing water treatment, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as large fluctuation range, intensified corrosion, and inability to online disinfection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

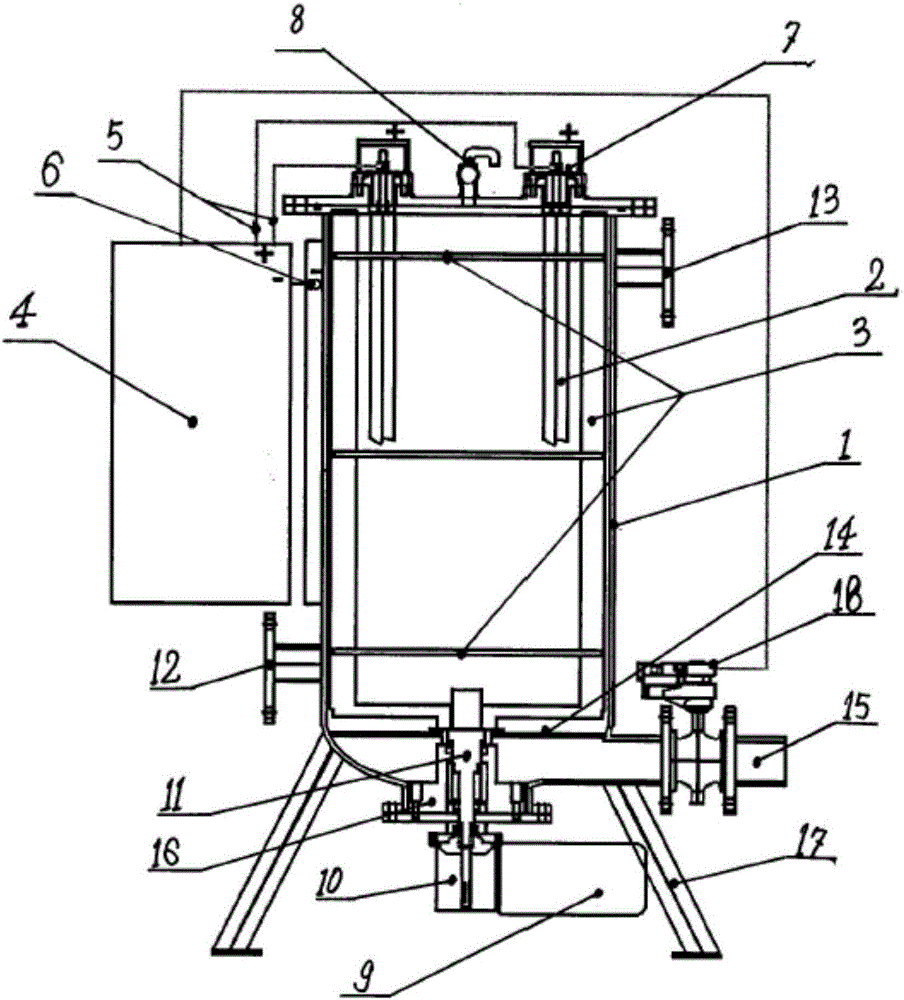

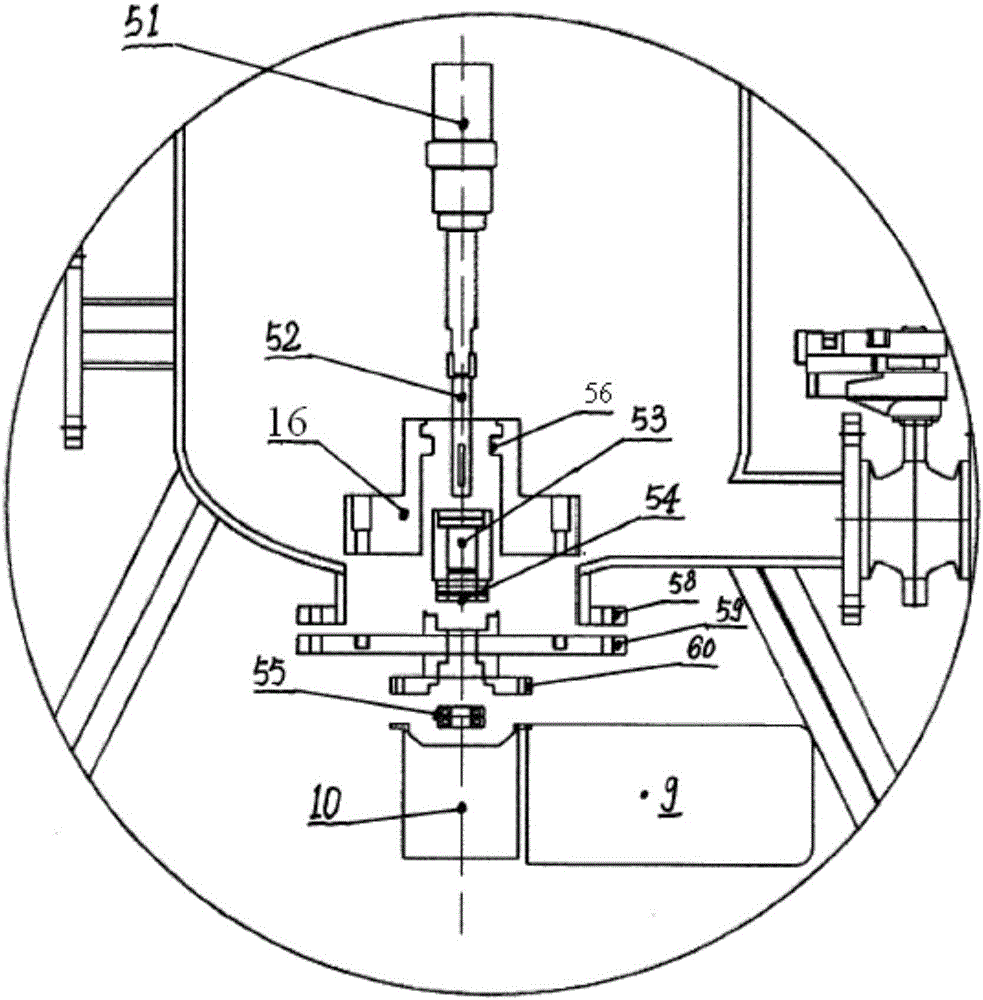

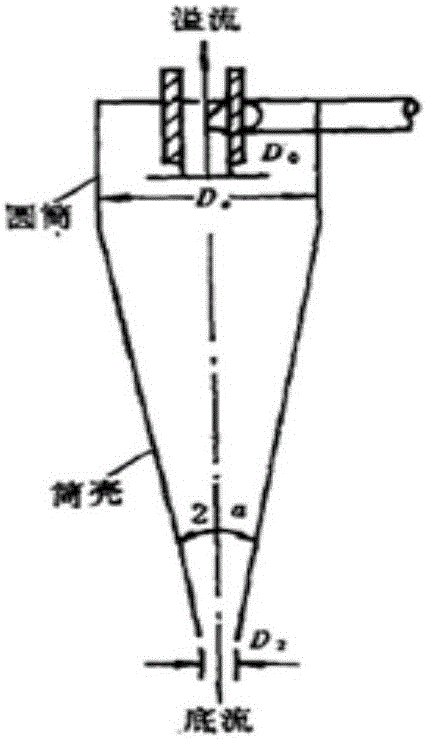

Embodiment 1

[0189] Three side flow water treatment devices are installed in the cooling circulating water system in the form of side flow, and the circulating water volume is 2000m 3 / h, the reserved volume is 1500m 3 , using two sets of side flow water treatment devices, the total treatment capacity of the side flow water treatment devices is 75m 3 / h, 24-hour continuous operation, processing 1800m a day 3 , the water to be treated at a temperature of 15-40°C enters the reaction chamber from the inlet of the reaction chamber. The reaction chamber itself is the cathode of the electrolysis process, and the inside of the reaction chamber is provided with an anode. The anode is V-shaped, with a total width of The length is 50mm and the length is 800mm. There is a scraper between the cathode and the anode. The scraper motor starts the scraper according to the instructions given by the controller to scrape off the precipitated scale or deposited suspended solids and heavy metals on the surfac...

Embodiment 2

[0215] The first and second phases of the evaporative condenser bypass electrolytic water processor (ECT) in a food factory were installed in April 2014 and put into use in May of the same year. There are 8 evaporative condensers in the first and second phases, each of which is opened irregularly, with a total circulating water volume of 1,736m 3 / h. A total of 19 ammonia compressors are in service, each of which is turned on irregularly. Four ECTs are used, installed in the form of side flow, and run continuously for 24 hours. The water to be treated at a temperature of 15-40°C enters the reaction chamber from the inlet of the reaction chamber. The reaction chamber itself is the cathode of the electrolysis process, and the inside of the reaction chamber is provided with an anode. The anode is V-shaped and has a total width of 50mm, length 800mm, there is a scraper between the cathode and the anode, the scraper motor starts the scraper according to the instructions given by ...

Embodiment 3

[0257] In a new workshop of a food processing factory, the evaporative condenser side-flow electrolytic water processor (ECT electrolytic water processor) was installed at the end of May 2014 and put into use in July of the same year. There are 10 evaporative condensers in the first workshop, each of which is opened irregularly, with a total circulation of 1,363m 3 / h, a total of 31 compressors, each of which is turned on irregularly.

[0258] The circulating water treatment system of the workshop uses 3 sets of ECT equipment with a treatment capacity of 30m 3 / h; Since the equipment is installed in the refrigeration room, we choose a flow rate of 50m 3 / h, Yangcheng 15m circulating water pump; the water intake is at the sewage pipe of each evaporative cooling unit, and the DN50 pipe is connected to the main water inlet pipe of DN100, and a valve is installed at each sewage pipe to adjust the flow; The water treated by the ECT system is evenly distributed to each evaporative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com