Preparation method of stable carbon source organic fertilizer

A technology of organic fertilizer and carbon source, which is applied in the field of preparation of stable carbon source organic fertilizer, can solve problems such as the decrease of organic carbon content, and achieve the effects of small bulk density, improved water and fertilizer retention, and full utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the stable carbon source organic fertilizer adopts the following process steps:

[0024] (1) Configuration of basic materials: select cow dung: mushroom dregs: seaweed dregs with a volume ratio of 2:1: (0-0.05), and mix them in stacks with forklifts in proportion. The cow dung mentioned is fresh cow dung or dry dung. Cow dung, mushroom dregs and seaweed dregs are naturally air-dried; said seaweed dregs can be selected from commercially available products.

[0025] The forklift piles up a long pile with a width of 3.5 meters, a height of 0.8 meters, and a length of 160 meters. It is broken and mixed with a self-propelled stacker. The first pass is faster, and the low gear is slow, and the speed is > 1000 rpm; base material.

[0026] (2) Blending and mixing: add decomposing bacteria agent to the basic material, the amount added is 0.05-0.2% of the total weight of the basic material, preferably 0.1% in spring and autumn, 0.05% in summer, and 0.2%...

Embodiment 1

[0033] Embodiment 1: The preparation method of this stable carbon source organic fertilizer adopts the following specific processes.

[0034] (1) The basic material is composed of cow dung: mushroom dregs = 2:1 volume ratio.

[0035] (2) Deployment and mixing: the season is summer, add decomposing bacteria agent to the basic material, the addition amount is 0.05% of the total weight of the basic material, add water to the water content of 55wt%.

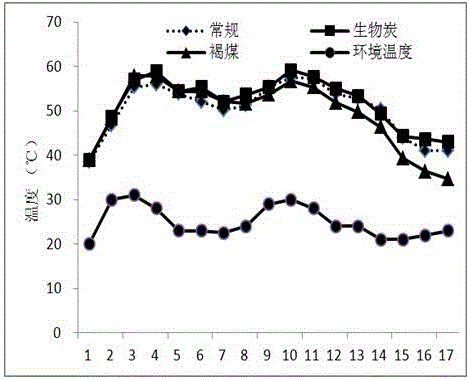

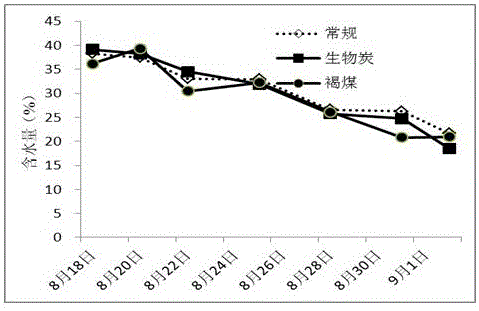

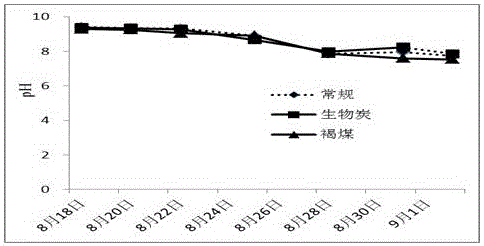

[0036] (3) Fermentation: turn the pile when the temperature rises to 58°C, and keep the moisture content at 55wt%; when the temperature reaches 50-70°C again and every time the monitoring reaches 50-70°C, add 5% of the total mass of the basic material % biochar, while adding water to ensure that the water content is 45-55wt%; figure 1 , 2 , 3 shown. The fermentation time is about 18 days to obtain the stable carbon source organic fertilizer. The stable carbon source organic fertilizer has a water content of about 30%, an organic ...

Embodiment 2

[0037] Embodiment 2: The preparation method of this stable carbon source organic fertilizer adopts the following specific processes.

[0038] (1) The basic material is composed of cow dung: mushroom dregs: seaweed dregs = 2:1:0.03 volume ratio.

[0039] (2) Deployment and mixing: the season is autumn, add decomposing bacteria agent to the basic material, the amount added is 0.1% of the total weight of the basic material, and water is added until the water content is 50wt%.

[0040] (3) Fermentation: turn the pile when the temperature rises to 50°C, and keep the moisture content at 50wt%; when the temperature reaches 50-70°C again and every time the monitoring reaches 50-70°C, add 8% of the total mass of the basic material % lignite, while adding water still ensures that the water content is 45-55wt%. It takes about 22 days from the establishment of the heap to the completion of decomposing. The organic matter of the obtained stable carbon source organic fertilizer is about 25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com