System integrating fatty group or ring group diisocyanate synthesis and separation and purification and synthesis method

A diisocyanate, separation and purification technology, applied in the purification/separation of isocyanic acid derivatives, chemical industry, organic chemistry, etc., can solve the problems of low yield and low conversion rate of diisocyanate, and achieve the effect of high purity of crude products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

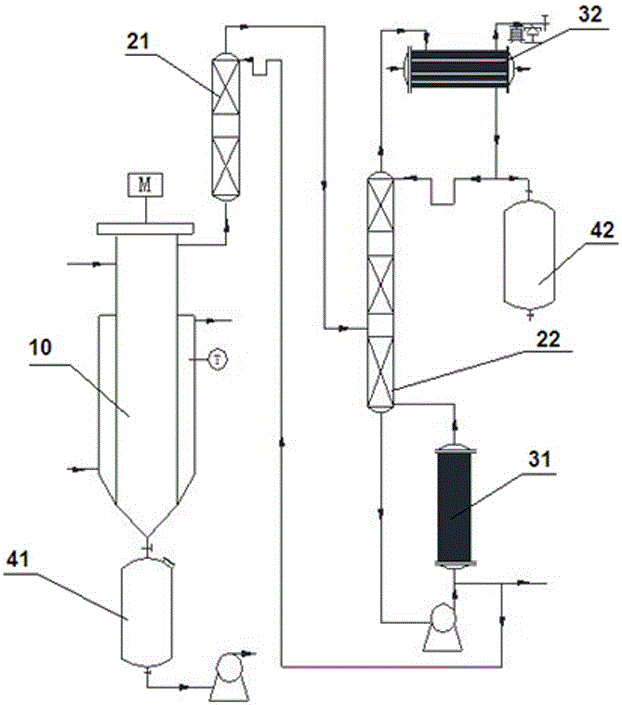

[0026] Such as figure 1 Shown is a system that integrates the synthesis, separation and purification of aliphatic or cyclic diisocyanates provided by the present invention, the system includes: a wiped film evaporator 10, a first rectification tower 21, a second rectification tower 22, First heat exchanger 31, second heat exchanger 32; Described wiped film evaporator 10 pipes communicate with the first rectification tower 21, and the outlet pipe of the first rectification tower 21 is communicated with the second rectification tower 22 In the middle, the bottom of the second rectification tower 22 communicates with the first heat exchanger 31 , and the top of the second rectification tower 22 communicates with the second heat exchanger 32 . The first rectification column 21 and the second rectificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com