Preparation method of silk fibroin-based nano MOFs (metal-organic frameworks)

A silk fibroin, nanotechnology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the fields that do not involve the interaction between rare earth ions and silk fibroin macromolecules and their possible applications, etc. problems, to achieve the effects of good biocompatibility and safety, simple preparation method and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

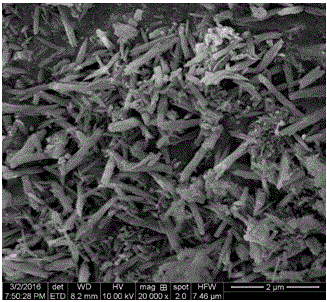

[0021] Example 1 0.1g silk was degummed, and 40mL of calcium chloride aqueous solution containing ethanol (CaCl 2 :EtOH:H 2 O=1:2:8, reaction temperature is 70~80°C) dissolve it until clarified, cool, filter with gauze to remove impurities, put the filtrate into dialysis bag and put it into deionized water for dialysis, dialysis for 3 days, change every day water three times to obtain a silk fibroin solution with a concentration of 2.5g / L, and slowly add 200μLEu 3+ , Molecular self-assembly reaction for 2 days, the solution was turbid, solid particles were formed, filtered out, rinsed repeatedly with deionized water, and dried at room temperature, the preparation was as shown in the accompanying drawing figure 1 The nanostructured silk fibroin-based MOFs material shown.

Embodiment 2

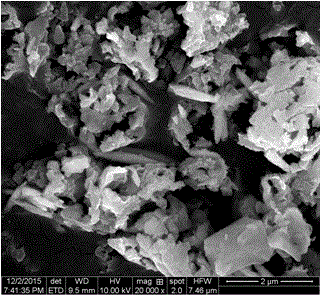

[0022] Example 2 0.1g silk was degummed, and 40mL of calcium chloride aqueous solution containing ethanol (CaCl 2 :EtOH:H 2 O=1:2:8, reaction temperature is 70~80°C) dissolve it until clarified, cool, filter with gauze to remove impurities, put the filtrate into dialysis bag and put it into deionized water for dialysis, dialysis for 3 days, change every day water 3 times to obtain a silk fibroin solution with a concentration of 2.5g / L, and slowly add 400μLEu 3+ , Molecular self-assembly reaction for 2 days, the solution was turbid, solid particles were formed, filtered out, rinsed repeatedly with deionized water, and dried at room temperature, the preparation was as shown in the accompanying drawing figure 2 The nanostructured silk fibroin-based MOFs material shown.

Embodiment 3

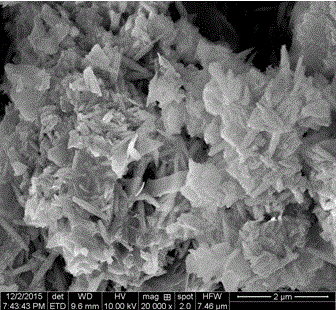

[0023] Example 3 0.1g silk was degummed, and 40mL of calcium chloride aqueous solution containing ethanol (CaCl 2 :EtOH:H 2 O=1:2:8, reaction temperature is 70~80°C) dissolve it until clarified, cool, filter with gauze to remove impurities, put the filtrate into dialysis bag and put it into deionized water for dialysis, dialysis for 3 days, change every day water 3 times to obtain a silk fibroin solution with a concentration of 2.5g / L, and slowly add 600μLEu 3+ , Molecular self-assembly reaction for 2 days, the solution was turbid, solid particles were formed, filtered out, rinsed repeatedly with deionized water, and dried at room temperature, the preparation was as shown in the accompanying drawing image 3 The nanostructured silk fibroin-based MOFs material shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com