Micro-electronic multilayer metal film etching liquid and application thereof

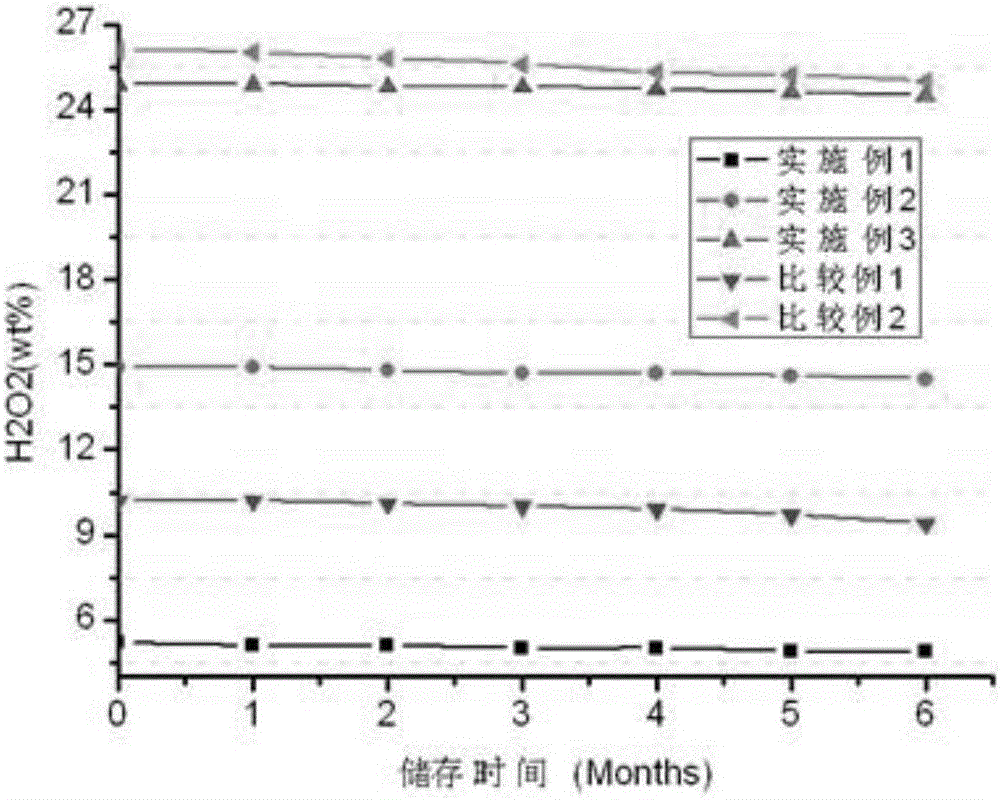

A multi-layer metal and etchant technology, which is applied in the field of multi-layer metal film etchant for microelectronics, can solve the problem of unclear edge shape of side-etched patterns, smaller line width of side-etched metal wiring, difficulty in controlling Cu dissolution rate, etc. problems, to achieve the effects of slowing down the etching speed, reducing the defective rate, and improving storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following describes the present invention in further detail with reference to specific embodiments, but the present invention is not limited to the following embodiments.

[0033] The invention provides a multilayer metal film etching solution for microelectronics, which is mainly used for wet etching of copper, molybdenum or molybdenum alloy metal films. The etching solution can etch the Cu / Mo metal layer at one time at a certain temperature to obtain a flat cross section and a good taper angle.

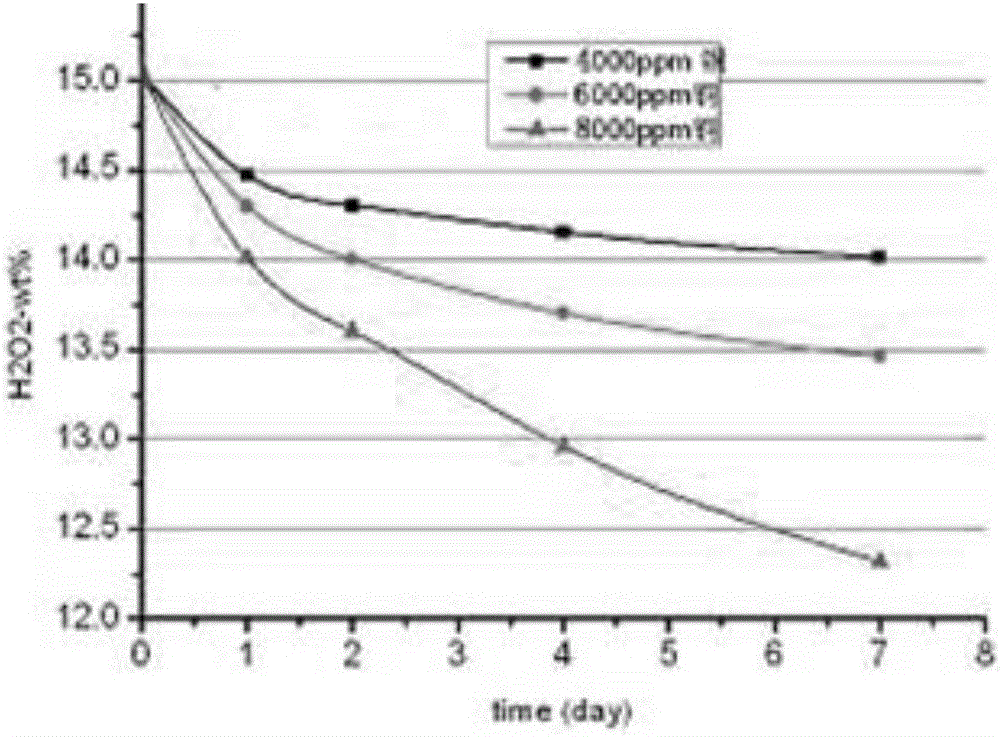

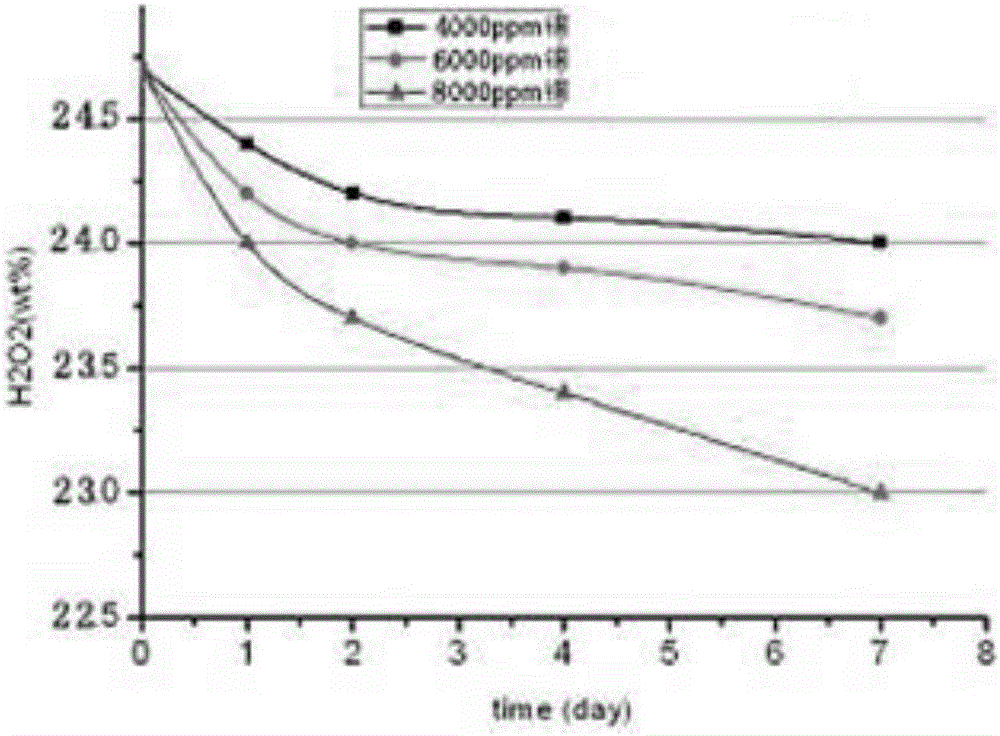

[0034] Specifically, the raw material formula of the etching solution of the present invention includes: in terms of weight percentage, the raw material formula of the etching solution includes hydrogen peroxide 5-25%, auxiliary acid 3-10%, hydrogen peroxide stabilizer 2~ 10%, cone angle control agent 0.001-1%, additive 0.1-1%, the balance is ultrapure water.

[0035] In the etching solution of the present invention, hydrogen peroxide is used as an oxidant, and its content is b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com