Flexible polar line for wet type electrostatic dust collector

A wet precipitator and flexible technology, applied in the environmental protection field of deep purification of flue gas, can solve the problems such as affecting the normal operation of the electrostatic precipitator, the slender rods are easy to bend and deform, and the discharge tip cannot be very sharp, so as to achieve the problem of not sticking and sticking. Dust, eliminate the discharge dead zone problem, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

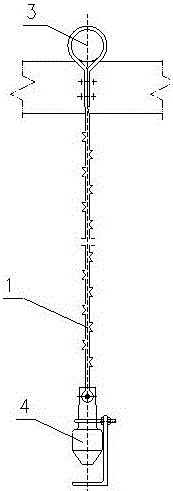

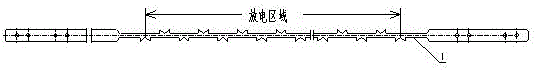

[0026] Such as figure 1 , figure 2 As mentioned above, the flexible polar wire of the wet dust collector of the present invention includes a cathode wire body 1 made of titanium alloy material. The cathode wire body 1 is twisted from a strip-shaped motherboard, and the twisted body has a spiral strip structure . The outer surface of the discharge area of the cathode wire body 1 is provided with multiple sets of sawtooth discharge tips in gaps along the spiral direction. Each set of sawtooth discharge tips adopts a double-tooth structure. The double-tooth design helps to generate more electrons and helps dust and liquid discharge. drip charge. The distance between two adjacent groups of sawtooth discharge tips (the twisted helical pitch is about 600-800mm) is 30-80mm. A positioning hole is respectively arranged at the upper and lower ends of the cathode wire body. During processing, first use a numerical control punching machine to punch out multiple groups of sawtooth ...

Embodiment 2

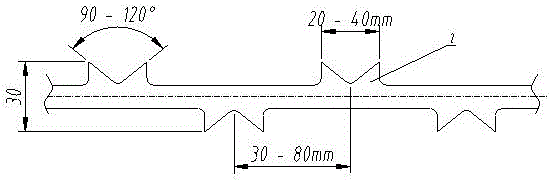

[0030] Such as Figure 3-Figure 4 As shown, the flexible polar line of the wet dust collector of the present invention adopts a strip-shaped strip with a thickness of 0.8-1.2mm and a width of 30mm, and a plurality of φ9 mounting holes are punched out at both ends, and the discharge area is separated by a numerically controlled punch. Regular M-shaped sawtooth 2 punched out evenly, the distance between two adjacent M-shaped sawtooths is 30-80mm, the distance between two discharge points in each M-shaped sawtooth is 20-40mm, the tooth height is 8-12mm, and the tip Dimensions can be fine-tuned according to flue gas conditions. Then the discharge area is twisted into a helical strip structure, and the discharge characteristics of the pole line can be adjusted by the spacing of the M-shaped sawtooth and the sharp angle of the tooth tip.

[0031] According to the needs of different working conditions, the cathode wire can be made of titanium alloy, C276 or various duplex stainless ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com