Preparation method of reduced molybdenum oxide quantum dot material

A technology of quantum dot material and molybdenum oxide, which is applied in molybdenum oxide/molybdenum hydroxide, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problem that the synthesis method of molybdenum oxide quantum dot material has not been realized, and achieve Strong near-infrared absorption ability, low reaction temperature, and uniform shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The amount of reducing agent is 0.5g chitosan in the present example, and concrete preparation steps are as follows:

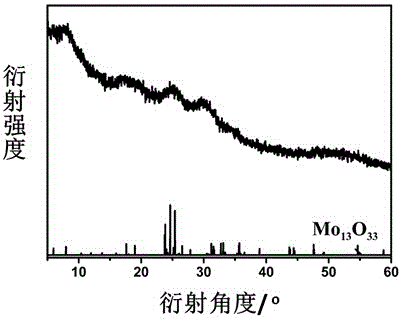

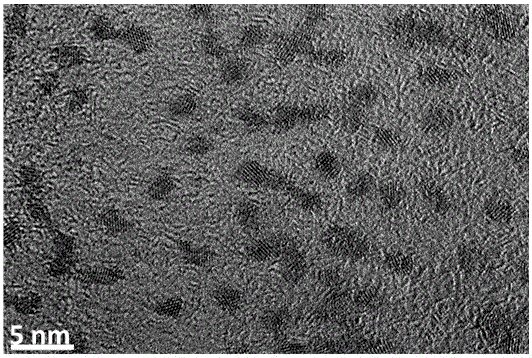

[0030] Add 10ml of 30% hydrogen peroxide to a 100ml hydrothermal reaction kettle, add 1g of molybdenum powder under magnetic stirring until all are mixed and dissolved, then add 30ml of a solution containing 0.5g of chitosan, and then crystallize at 80°C for 12 hours. After cooling to room temperature, the sample was alternately washed with deionized water and absolute ethanol, centrifuged, and vacuum-dried to obtain a powder sample. Such as figure 2 As shown, the sample prepared in this embodiment is Mo with a diameter of about 2.2nm 13 o 33 quantum dots.

Embodiment 2

[0032] The amount of reducing agent is 2g chitosan in the present example, and concrete preparation steps are as follows:

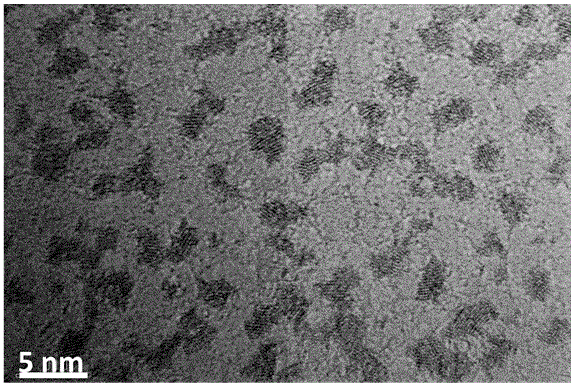

[0033] Add 10ml of 30% hydrogen peroxide to a 100ml hydrothermal reaction kettle, add 1g of molybdenum powder under magnetic stirring until all are mixed and dissolved, then add 30ml of a solution containing 2g of chitosan, and then crystallize at 80°C for 12 hours. After cooling to room temperature, the sample was alternately washed with deionized water and absolute ethanol, centrifuged, and vacuum-dried to obtain a powder sample. Such as image 3 As shown, the sample prepared in this embodiment is Mo with a diameter of about 3nm 13 o 33 quantum dots.

Embodiment 3

[0035] The amount of reducing agent is 5g chitosan in the present example, and concrete preparation steps are as follows:

[0036] Add 10ml of 30% hydrogen peroxide to a 100ml hydrothermal reaction kettle, add 1g of molybdenum powder under magnetic stirring until all are mixed and dissolved, then add 30ml of a solution containing 5g of chitosan, and then crystallize at 80°C for 12 hours. After cooling to room temperature, the sample was alternately washed with deionized water and absolute ethanol, centrifuged, and vacuum-dried to obtain a powder sample. Such as Figure 4 As shown, the sample prepared in this embodiment is Mo with a diameter of about 2nm 13 o 33 quantum dots.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com