Biochemical device for integrally treating exhaust gas and sewage and treatment method thereof

A waste gas and sewage technology, applied in chemical instruments and methods, separation methods, biological treatment devices, etc., can solve the problems of short gas-liquid flow, small amount of film formation, and uneven accumulation, so as to eliminate packing blockage and facilitate maintenance in the later stage , the effect of short domestication time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

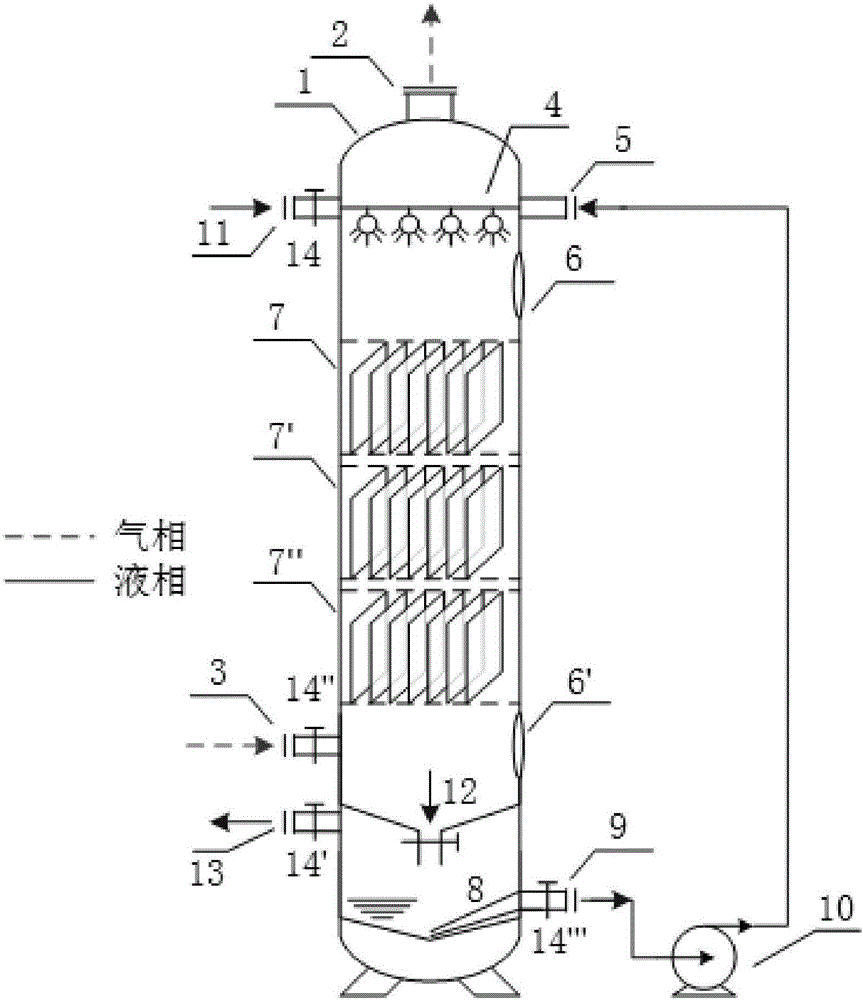

[0036] Embodiment 1, the method for treating exhaust gas according to the present invention includes the following steps:

[0037]1) Close the valve 14 ′, and according to the properties of waste gas treatment, add circulating nutrient liquid and biological strains of different components into the reaction through the valve 14 . The strains can be taken from the activated sludge of urban domestic sewage treatment plants.

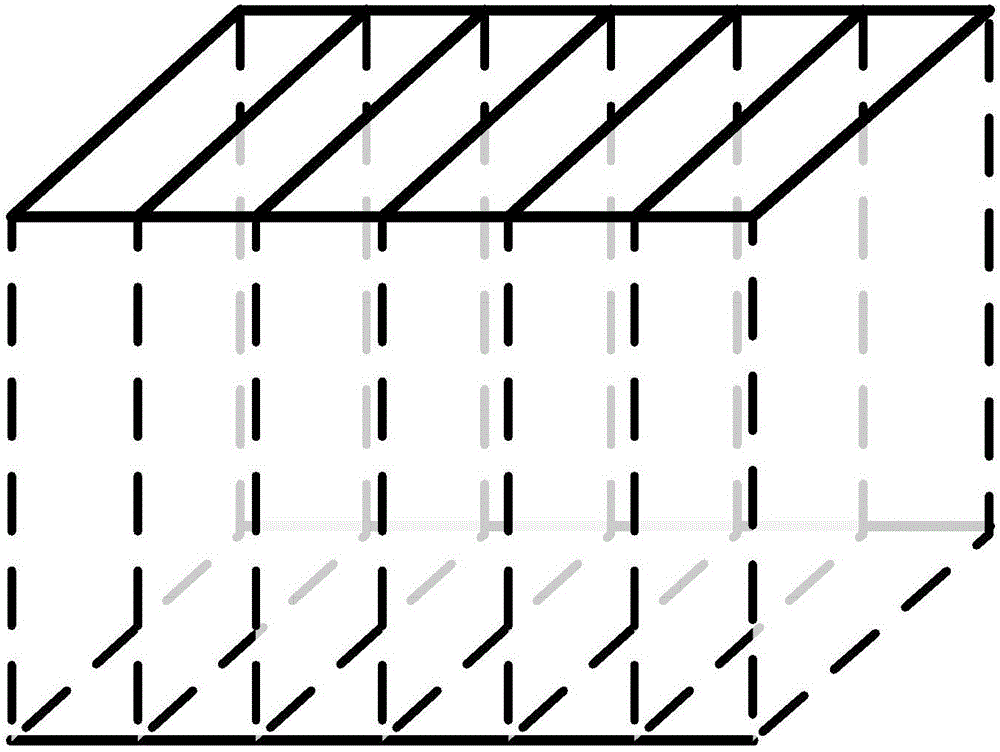

[0038] 2) Close the valve 14, circulate the circulating nutrient solution and biological strains in the reactor repeatedly through the circulating water pump 10, and evenly spray on the whole enzyme floating packing 7, 7', 7", and flow into the water collection area 12.

[0039] 3) The valve at the bottom of the water collection area 12 is opened to maintain the same flow rate as the circulating fluid outlet 9 . Finally, the circulating nutrient solution entrained with microorganisms flows into the sedimentation zone 8 and is repeatedly circulated through t...

Embodiment example 2

[0042] Implementation case two, the method for treating sewage of the present invention may further comprise the steps:

[0043] 1) Close the valve 14', open the valves 14, 14" and 14"', let the sewage and biological bacteria enter the spraying device 4 through the sewage inlet, and then close the valve 14".

[0044] 2) The mixture of sewage and biological strains is evenly sprayed onto the whole enzyme floating packing 7, 7', 7", and flows into the catchment area 12. The valve at the bottom of the catchment area 12 is properly opened according to the quality of the influent water.

[0045] 3) Fresh air enters the reactor tower body 1 through the exhaust gas inlet 3, and controls the amount of air inflow by adjusting 14". After 1 to 2 weeks of domestication and debugging, the whole enzyme floating packing 7, 7', 7" With a uniform biofilm attached, sewage can be effectively degraded.

[0046] 4) Open the valve 14 again to continuously flow in the sewage and open the valve 14' ...

Embodiment example 3

[0047] Implementation case three, the combined treatment method of sewage and waste gas of the present invention, comprises the following steps:

[0048] 1) Close the valve 14', open the valves 14, 14" and 14"', let the sewage and biological bacteria enter the sedimentation zone 8 through the sewage inlet, and then close the valve 14".

[0049] 2) Sewage and biological strains flow through the circulating fluid outlet 9, the circulating water pump 10, the circulating fluid inlet 5, and the spraying device 4, and are evenly sprayed onto the whole enzyme floating packing 7, 7', 7", and flow into the catchment area 12.

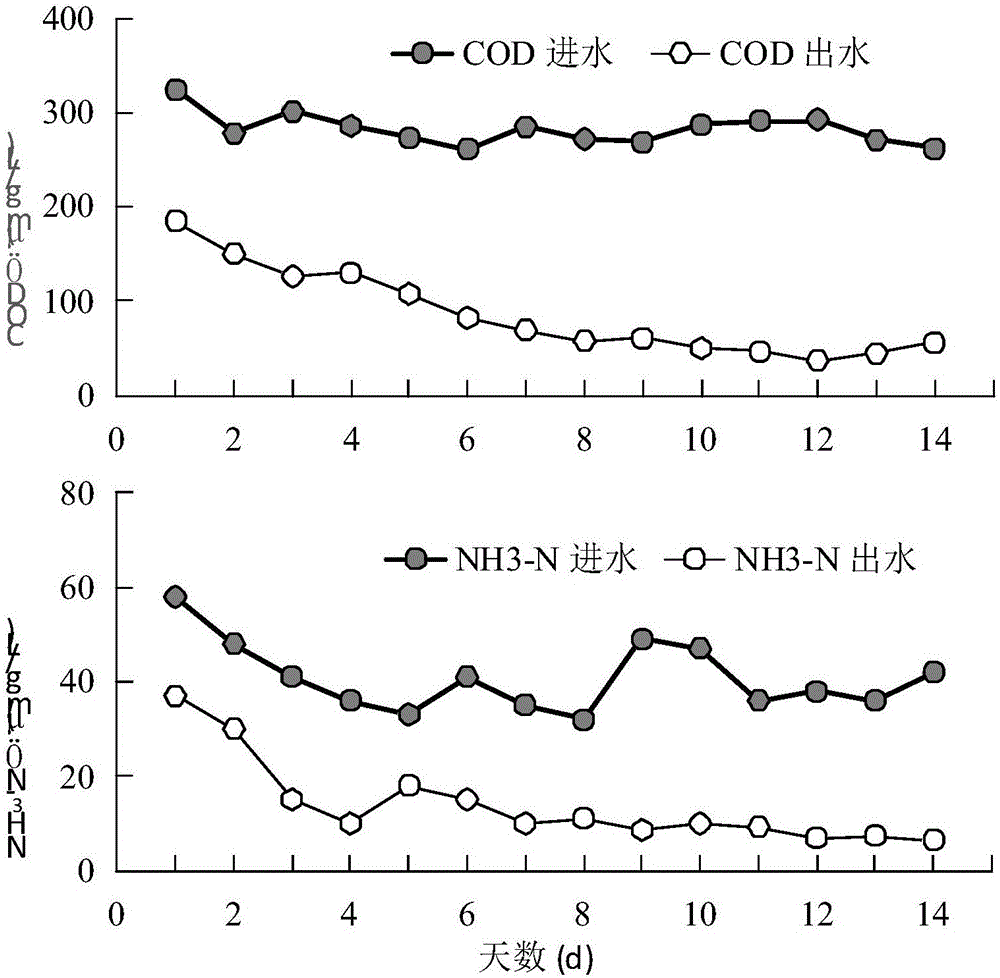

[0050] 3) The valve at the bottom of the catchment area 12 is moderately opened according to the quality of the influent water. If the influent NH 3 -N concentration is high, the opening degree is increased, and the denitrification rate is increased.

[0051] 4) Odor gas or low-concentration organic waste gas enters the reactor tower body 1 through the waste ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com