A paper-making black liquor modified sulfamate high-efficiency water reducer and its preparation method

A technology of sulfamic acid salt and high-efficiency water reducer, which is applied in the field of concrete materials, can solve the problems of phenol and formaldehyde volatilization, small concrete slump, and high production cost, so as to improve recovery efficiency, reduce bleeding phenomenon, and save The effect of processing fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

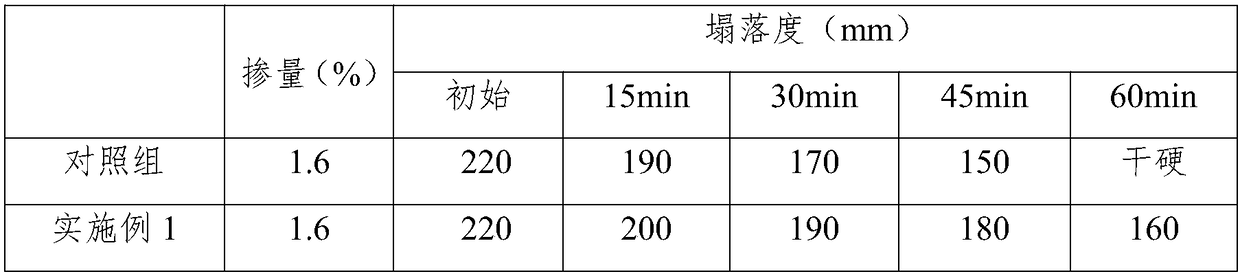

Examples

Embodiment 1

[0018] A paper-making black liquor modified sulfamate high-efficiency water reducer, which is prepared from the following components in parts by weight: 136 parts of sodium p-aminobenzenesulfonate, 50 parts of paper-making black liquor, 24 parts of sulfur dioxide, and 60 parts of phenol , 170 parts of formaldehyde, 22 parts of 30% liquid caustic soda, 12 parts of urea, 300 parts of water.

[0019] The preparation method of papermaking black liquor modified sulfamate high-efficiency water reducer comprises the following steps:

[0020] 1) Feed sulfur dioxide into the paper-making black liquor at a certain rate within 20 minutes, and conduct the closed reaction for 20 minutes for complete sulfonation to obtain sulfonated paper-making black liquor;

[0021] 2) Heat the water in the reactor to 40°C, add sodium p-aminobenzenesulfonate, urea, and phenol in turn while stirring, heat to 60°C while stirring, add liquid caustic soda to adjust the pH value, stir, and continue heating to ...

Embodiment 2

[0030] A paper-making black liquor modified sulfamate high-efficiency water reducer, which is prepared from the following components in parts by weight: 132 parts of sodium p-aminobenzenesulfonate, 40 parts of paper-making black liquor, 20 parts of sulfur dioxide, and 58 parts of phenol , 165 parts of formaldehyde, 20 parts of 30% liquid caustic soda, 11 parts of urea, 260 parts of water.

[0031] The preparation method of papermaking black liquor modified sulfamate high-efficiency water reducer comprises the following steps:

[0032] 1) Feed sulfur dioxide into the paper-making black liquor at a certain rate within 20 minutes, and conduct the closed reaction for 20 minutes for complete sulfonation to obtain sulfonated paper-making black liquor;

[0033] 2) Heat the water in the reactor to 40°C, add sodium p-aminobenzenesulfonate, urea, and phenol in turn while stirring, heat to 60°C while stirring, add liquid caustic soda to adjust the pH value, stir, and continue heating to ...

Embodiment 3

[0036] A paper-making black liquor modified sulfamate high-efficiency water reducer, which is prepared from the following components in parts by weight: 130 parts of sodium p-aminobenzenesulfonate, 60 parts of paper-making black liquor, 12 parts of sulfur dioxide, and 70 parts of phenol , 150 parts of formaldehyde, 30 parts of 30% liquid caustic soda, 9 parts of urea, 240 parts of water.

[0037] The preparation method of papermaking black liquor modified sulfamate high-efficiency water reducer comprises the following steps:

[0038] 1) Feed sulfur dioxide into the paper-making black liquor at a certain rate within 20 minutes, and conduct the closed reaction for 20 minutes for complete sulfonation to obtain sulfonated paper-making black liquor;

[0039] 2) Heat the water in the reaction kettle to 40°C, add sodium p-aminobenzenesulfonate, urea, and phenol in turn while stirring, heat to 60°C while stirring, add liquid caustic soda to adjust the pH value, stir, and continue heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com