High-viscosity asphalt modifying agent, preparation method and preparation method of modified asphalt

An asphalt modifier and modified asphalt technology are applied in the fields of high-viscosity asphalt modifier, preparation, and preparation of modified asphalt, which can solve the problems of poor low-temperature stability, poor low-temperature performance, and low asphalt viscosity of modified asphalt. Achieve the effect of good solubility, low cost and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

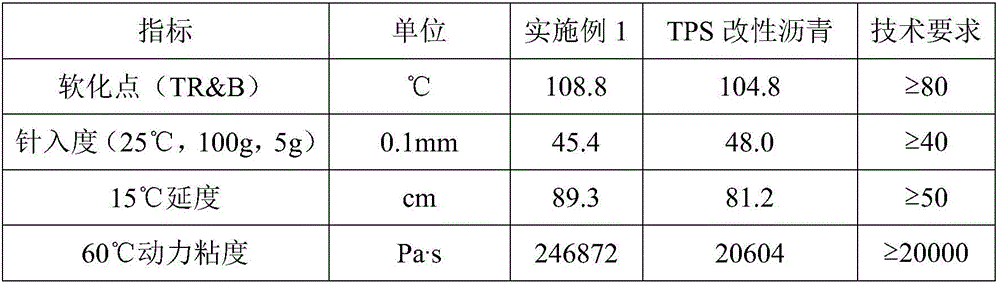

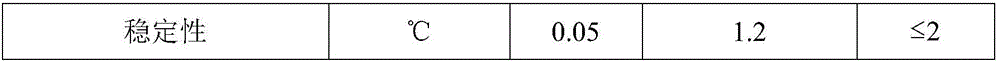

Examples

Embodiment 1

[0026] The composition of the high-viscosity asphalt modifier is as follows: 42 wt% of thermoplastic styrene-butadiene rubber polymer, which is a mixture of linear and star-shaped, with a weight-average molecular weight of 300,000; 26 wt% of modified styrene-butadiene rubber wherein polybutadiene Content 34%; Regenerated polyethylene 8wt%, is low-density linear polyethylene; Regenerated ethylene-vinyl acetate copolymer 18wt%, the content of vinyl acetate in regenerated ethylene-vinyl acetate copolymer is 48%; Sulfur crosslinking agent 3wt% and Diaryl secondary amine antioxidant stabilizer 3wt%.

[0027] The preparation method of high-viscosity asphalt modifier, comprises the steps:

[0028] (1) Mix each component evenly according to the corresponding proportion, add it to a pulverizer, select a liquid nitrogen tank to cool down with liquid nitrogen, and carry out low-temperature pulverization;

[0029] (2) Put the pulverized mixed components into the screw extruder through th...

Embodiment 2

[0042] The composition of the high-viscosity bitumen modifier is as follows: thermoplastic styrene-butadiene rubber polymer 50wt% part, thermoplastic styrene-butadiene rubber is two kinds of mixtures of linear and star, weight average molecular weight is 400,000; modified styrene-butadiene rubber 20wt% part, molecular weight 200,000, of which polybutadiene content is 40%; recycled polyethylene is 12wt%, recycled polyethylene is high-density linear polyethylene, recycled ethylene-vinyl acetate copolymer is 15wt%, and the content of vinyl acetate in recycled ethylene-vinyl acetate copolymer is The content is 60%; sulfur crosslinking agent 2wt% and p-phenylenediamine antioxidant stabilizer 1wt%.

[0043] The preparation method of high-viscosity asphalt modifier, comprises the steps:

[0044] (1) Mix each component evenly according to the corresponding proportion, add it to a pulverizer, select a liquid nitrogen tank to cool down with liquid nitrogen, and carry out low-temperature...

Embodiment 3

[0058] The composition of the high-viscosity asphalt modifier is as follows: thermoplastic styrene-butadiene rubber polymer 53wt% part, thermoplastic styrene-butadiene rubber is two kinds of mixtures of linear and star, the weight average molecular weight is 350,000; modified styrene-butadiene rubber 30wt% part, modified The molecular weight of styrene-butadiene rubber is 400,000, and the content of polybutadiene is 45%; the recycled polyethylene is 5wt%, and the recycled polyethylene is linear low-density linear polyethylene; the recycled ethylene-vinyl acetate copolymer is 8wt%, and the recycled ethylene-vinyl acetate The content of vinyl acetate in the copolymer is 50%, the sulfur crosslinking agent 2wt%, and the aldehyde-amine condensate type antioxidant stabilizer 2wt%.

[0059] The preparation method of high-viscosity asphalt modifier, comprises the steps:

[0060] (1) Mix each component evenly according to the corresponding proportion, add it to a pulverizer, select a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com