Method for preparing glyceride rich in EPA and DHA through enzyme catalysis

A technology for the catalytic preparation of glycerides, which is applied in the direction of fermentation, etc., can solve the problems of unmentioned recycling, unfavorable production safety, and waste of by-products, so as to increase the content of triglycerides, EPA and DHA, save investment, The effect of high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

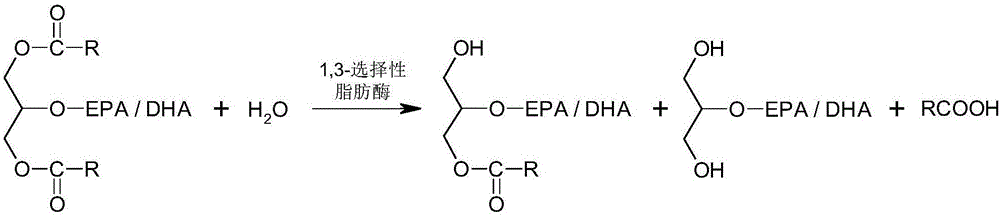

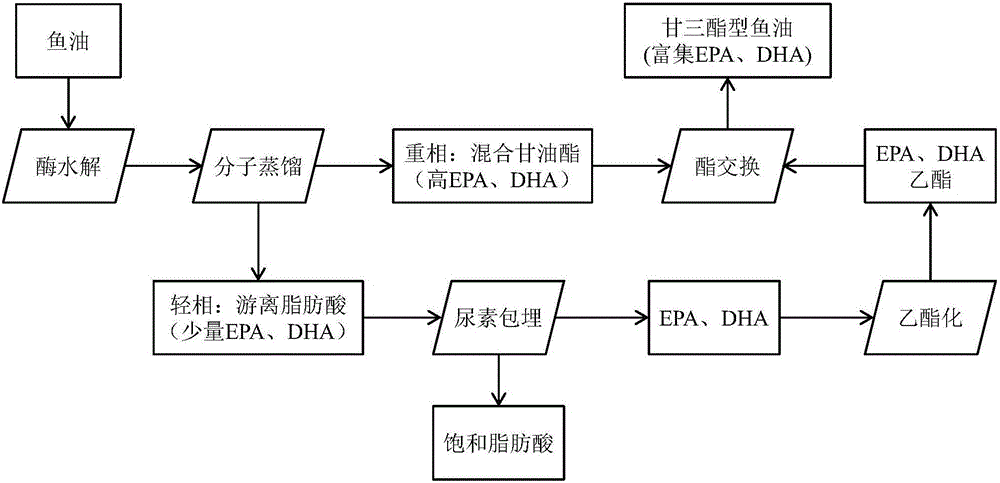

[0045] A kind of method that utilizes enzyme catalysis to prepare rich in EPA and DHA glyceride, technological process is as follows figure 2 shown, including the following steps:

[0046] (1) Add 30.0g of refined fish oil from Noah Sano Biological Co., Ltd., 30.0mL potassium phosphate buffer solution (0.1mol / L, pH=6) and 6.0mg of LipaseAY "Amano" 400SD from Japan Amano Enzyme Co., Ltd. 100mL Erlenmeyer flask, and fill the flask with nitrogen to exclude air, and seal it. Put the Erlenmeyer flask into a shaker, set the shaking rate to 200r / min, shaker temperature to 35°C, and maintain the reaction for 10h. After the reaction was completed, the resulting mixture was centrifuged to separate liquids. The resulting upper oil phase is a mixture of glycerides rich in EPA and DHA and free fatty acids, and the lower layer is an aqueous phase containing lipase.

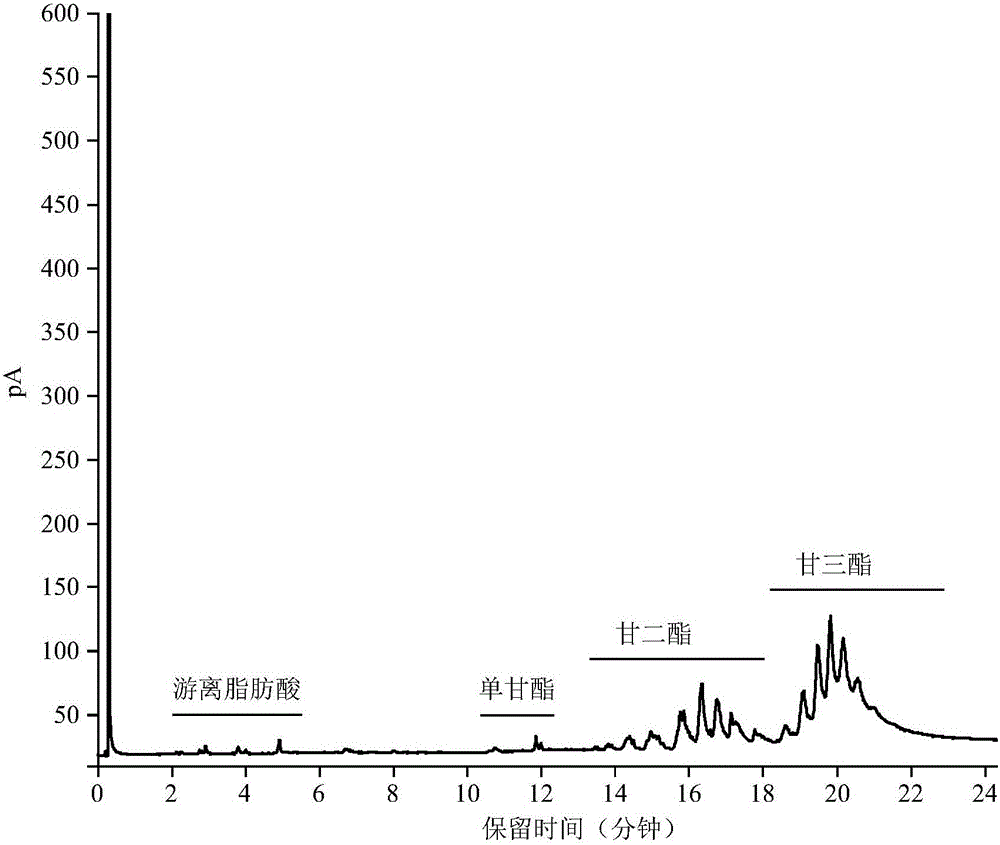

[0047] (2) A total of 200 g of the upper layer oil phase obtained in the aforementioned step (1) was accumulated, which w...

Embodiment 2

[0055] This implementation example is the same as embodiment 1 except the following technical features:

[0056] The buffer solution used in step (1) is 0.1mol / L potassium phosphate solution (pH7), the buffer solution volume used is 45mL; the amount of enzyme added is 15mg; the reaction temperature is 50°C, and the reaction time is 8h.

[0057] The temperature of the second stage molecular distillation used in step (2) is 140°C. After molecular distillation, the gained heavy phase quality is 106.6g, and corresponding productive rate is 53.3%; Contain 69.0% triglyceride, 30.0% diglyceride, 0.80% monoglyceride, 0.21% free fatty acid in the heavy phase; Among fatty acids, EPA accounts for 25.0%, and DHA accounts for 20.2%. The light phase obtained by molecular distillation is mainly free fatty acids mainly saturated fatty acids, with a mass of 81.2 g and a corresponding yield of 40.6%, in which EPA content is 12.4%, and DHA content is 1.95%.

[0058] The quality of 95% ethanol (v...

Embodiment 3

[0062] This implementation example is the same as embodiment 1 except the following technical features:

[0063] The buffer solution used in step (1) is 0.1mol / L potassium phosphate solution (pH6.5), the buffer solution volume used is 90mL; the amount of enzyme added is 3.0mg; the reaction temperature is 25°C, and the reaction time is 24h.

[0064] The temperature of the second stage molecular distillation used in step (2) is 160°C. After molecular distillation, the gained heavy phase quality is 100.1g, and corresponding productive rate is 50.1%; Contain 64.5% triglyceride, 34.0% diglyceride, 1.20% monoglyceride, 0.24% free fatty acid in the heavy phase; Among the fatty acids, EPA accounts for 23.2%, and DHA accounts for 20.1%. The light phase obtained by molecular distillation is mainly free fatty acids mainly saturated fatty acids, with a mass of 85.2 g, wherein the EPA content is 13.3%, and the DHA content is 2.53%.

[0065] The mass of 95% ethanol (95% ethanol by volume)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com