Preparation method of modified carbon nanotube/graphene-resin conductive fibers

A technology of conductive fibers and carbon nanotubes, which is applied in the chemical characteristics of fibers, textiles and papermaking, chemical post-processing of rayon, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Carbon nanotube / graphene-polyvinyl alcohol reinforced conductive fiber:

[0039] (1) Dissolve graphene in deionized water to prepare a 3mg / ml graphene solution, and ultrasonically disperse it for 1h; then add concentrated sulfuric acid and nitric acid (17:5) to the graphene solution to acidify the carbon nanotubes, and continue ultrasonic treatment for 2h , to obtain carbon nanotube / graphene composite spinning slurry 1;

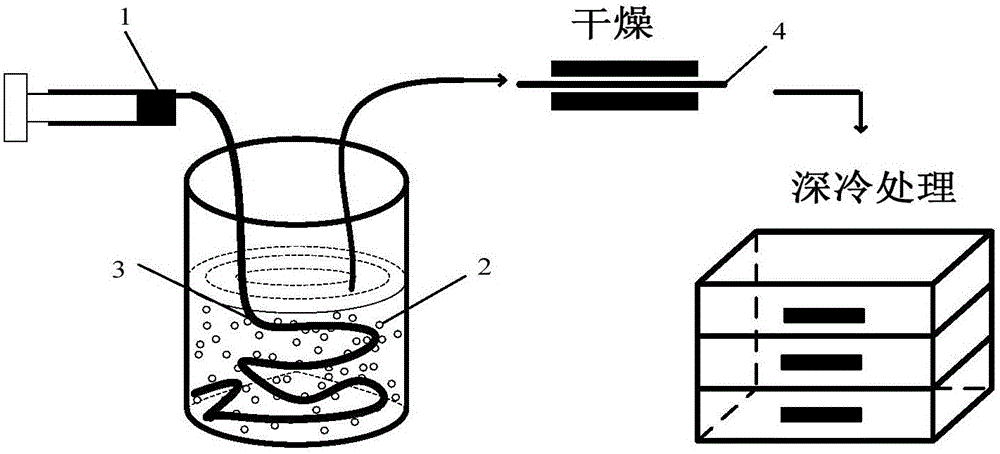

[0040] (2) The carbon nanotube / graphene composite spinning slurry 1 that step (1) obtains is passed through the spinneret that diameter is 40 μm with the extrusion speed of 100 μ L / min, and polyvinyl alcohol (concentration is 5% at 25 ℃) ) stay in the coagulation bath 2 for 3600s to obtain carbon nanotube / graphene-polyvinyl alcohol reinforced conductive fiber 3, and dry at 100°C to obtain dry carbon nanotube / graphene-polyvinyl alcohol reinforced conductive fiber 4;

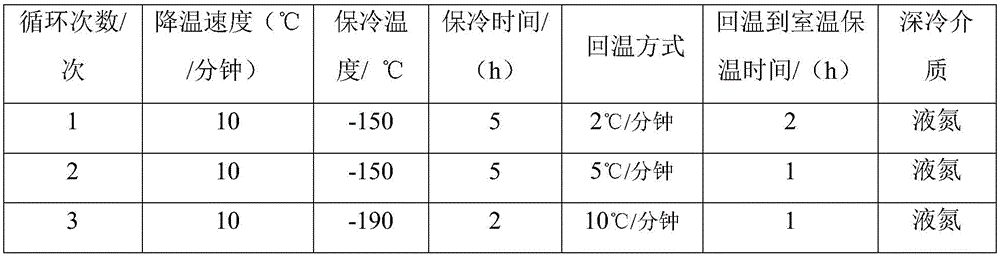

[0041] (3) The carbon nanotube / graphene-polyvinyl alcohol reinforced conductive fiber...

Embodiment 2

[0046] Carbon Nanotube / Graphene-Epoxy Reinforced Conductive Fibers:

[0047] (1) Dissolve graphene in deionized water and methanol mixture to prepare a 2mg / ml graphene solution, and ultrasonically disperse it for 1h; then add concentrated sulfuric acid and nitric acid (17:5) to the graphene solution to acidify the carbon nanotubes, Continue ultrasonic treatment for 2h to obtain carbon nanotube / graphene composite spinning slurry 1;

[0048] (2) The carbon nanotube / graphene composite spinning slurry 1 that step (1) obtains is passed through the spinning nozzle that diameter is 30 μm with the extrusion speed of 50 μ L / min, and the epoxy resin (concentration is 5% at 20 ℃) ) stay in the coagulation bath 2 for 1800s to obtain carbon nanotube / graphene-epoxy resin reinforced conductive fiber 3, and dry at 100°C to obtain dry carbon nanotube / graphene-epoxy resin reinforced conductive fiber 4;

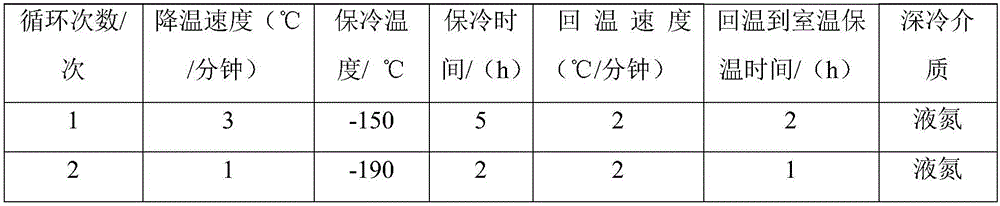

[0049] (3) The carbon nanotube / graphene-epoxy resin reinforced conductive fiber 4 is place...

Embodiment 3

[0054] Carbon nanotube / graphene-polydimethylsiloxane reinforced conductive fiber

[0055] (1) Dissolve graphene in deionized water to prepare a 2mg / ml graphene solution, and ultrasonically disperse it for 1h; then add concentrated sulfuric acid and nitric acid (17:5) to the graphene solution to acidify the carbon nanotubes, and continue ultrasonic treatment for 2h , to obtain carbon nanotube / graphene composite spinning slurry 1;

[0056] (2) The carbon nanotube / graphene composite spinning slurry 1 that step (1) obtains is passed through the spinning nozzle that the diameter is 100 μm with the extrusion speed of 80 μ L / min, in 10 ℃ polydimethylsiloxane ( Concentration is 5%) stay in coagulation bath 2 for 2700s, obtain carbon nanotube / graphene-polydimethylsiloxane reinforced conductive fiber 3, dry at 100 ℃, obtain dry carbon nanotube / graphene-polydimethylsiloxane Silicone reinforced conductive fibers 4;

[0057] (3) The carbon nanotube / graphene-polydimethylsiloxane reinforce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com