Large-current silicon on insulator lateral insulated gate bipolar transistor device

A bipolar transistor, silicon-on-insulator technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as destructive failure of device structure, thermal breakdown of devices, and reduced latch-up suppression capability, and reduce electron aggregation. level, the effect of improving the on-current density, and improving the latch-up suppression capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

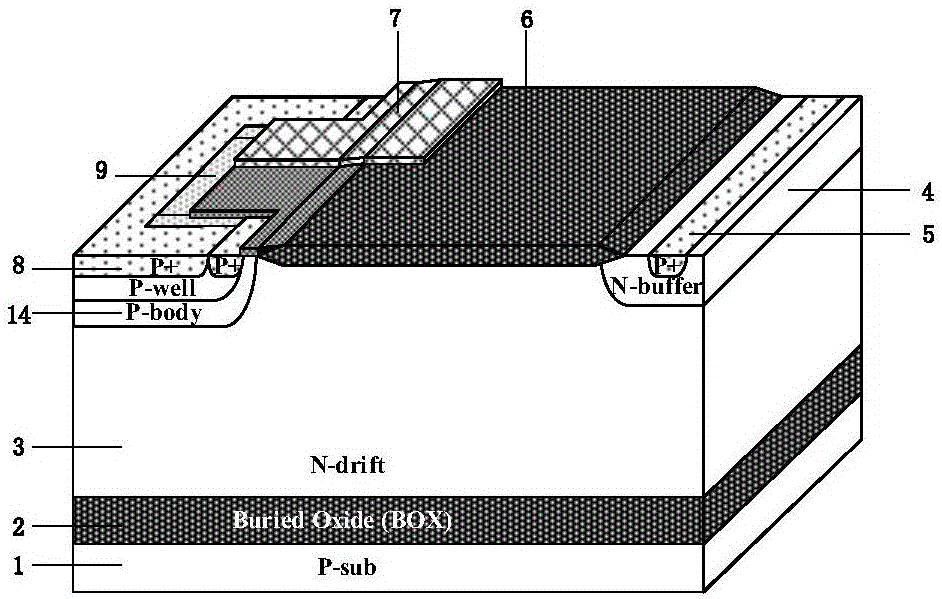

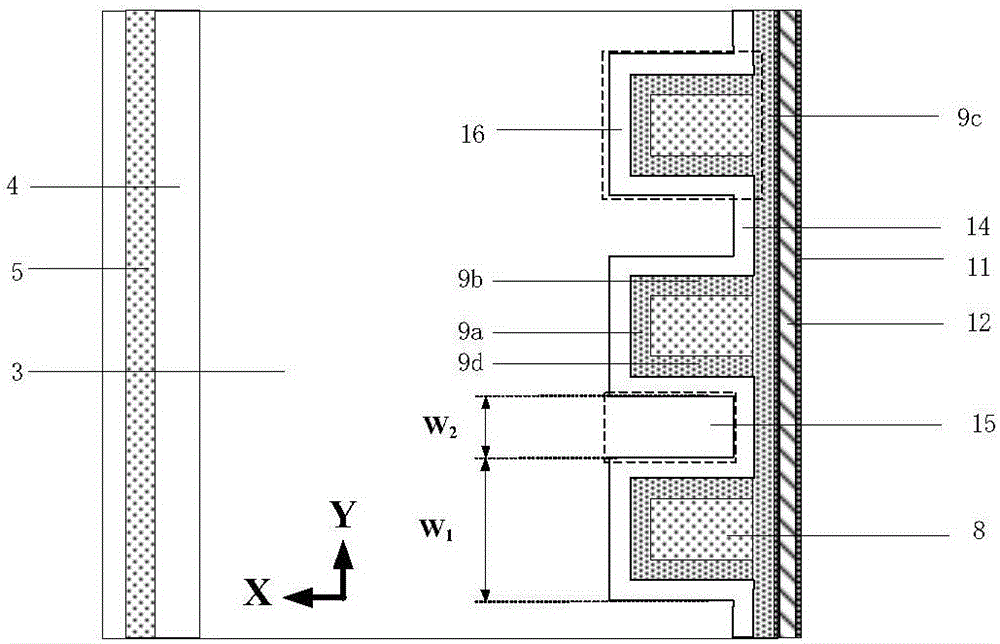

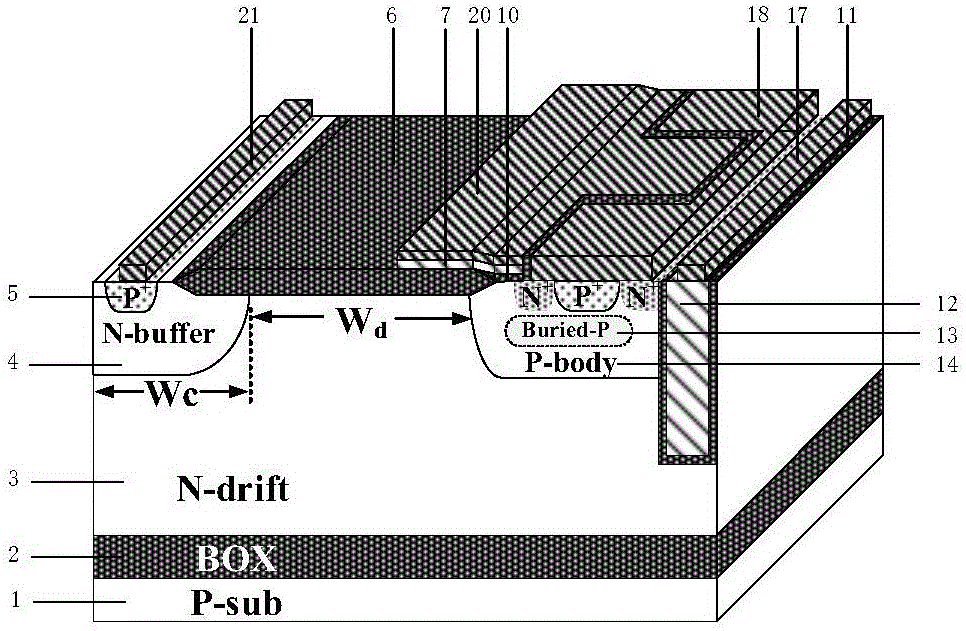

[0028] Combine below figure 2 , image 3 , Figure 4 , the present invention is described in detail:

[0029] A large current silicon-on-insulator lateral insulated gate bipolar transistor device, comprising: a P-type substrate 1, a buried oxygen 2 is arranged on the P-type substrate 1, and an N-type drift region 3 is arranged on the buried oxygen 2, An N-type buffer zone 4 and a P-type body region 14 are respectively arranged on both sides of the N-type drift region 3, and a heavily doped P-type collector region 5 is arranged in the N-type buffer region 4, and a heavily doped P-type collector region 5 is arranged. A collector metal 21 is connected to the electrode region 5, a heavily doped P-type emitter region 8 is provided in the P-type body region 14, and a heavily doped P-type emitter region 8 is provided around the heavily doped P-type emitter region 8. The N-type emitter region 9 is connected with the emitter metal 18 on the above-mentioned heavily doped P-type emit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com