Slope Strengthening Method Using High Performance Shotcrete

A sprayed concrete, high-performance technology, applied in excavation, construction, infrastructure engineering, etc., can solve the problems of damaging the surrounding landscape, reducing durability, and only focusing on functionality, etc., to achieve the effect of reducing construction costs and improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

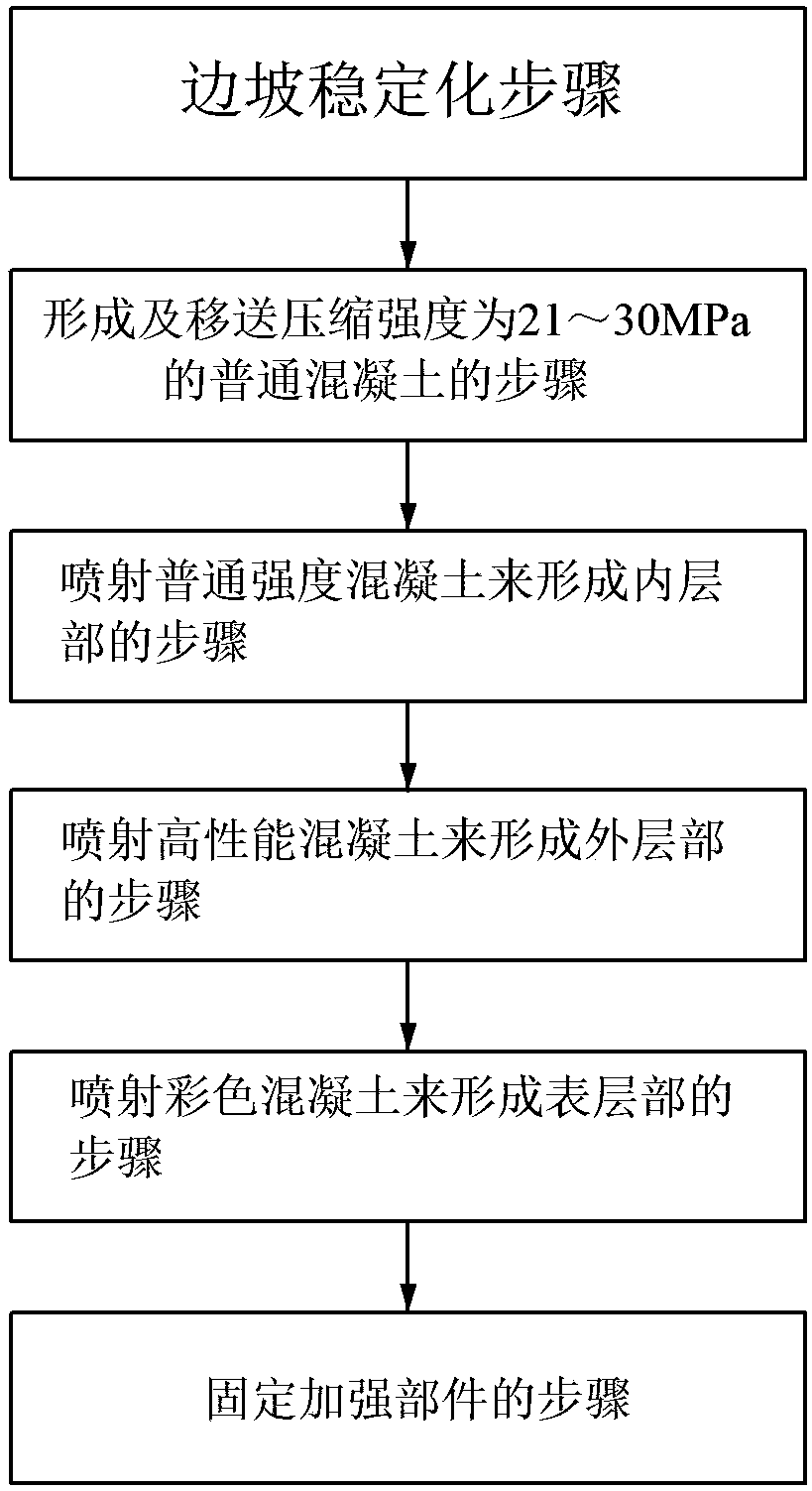

[0040] Hereinafter, the present invention will be described in detail with reference to the drawings. figure 1 It is a flowchart of the present invention.

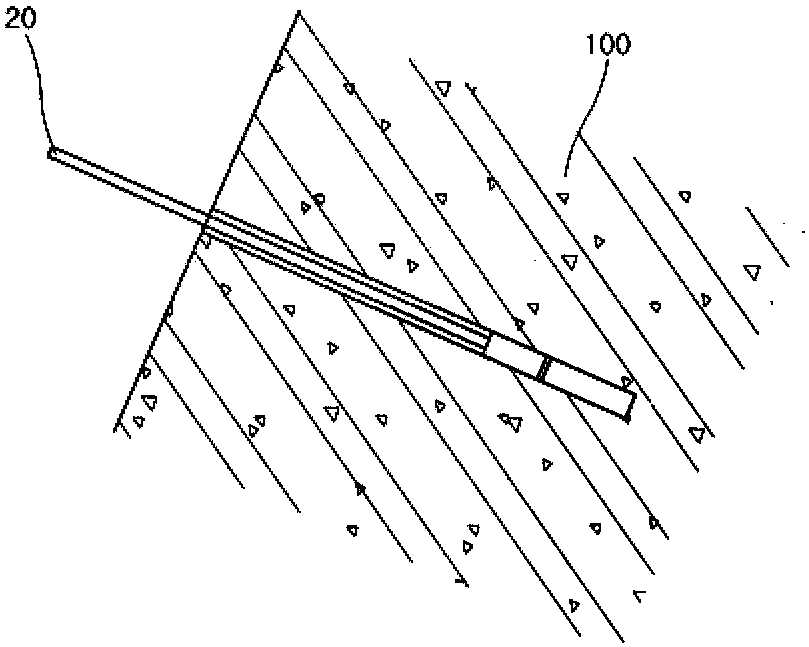

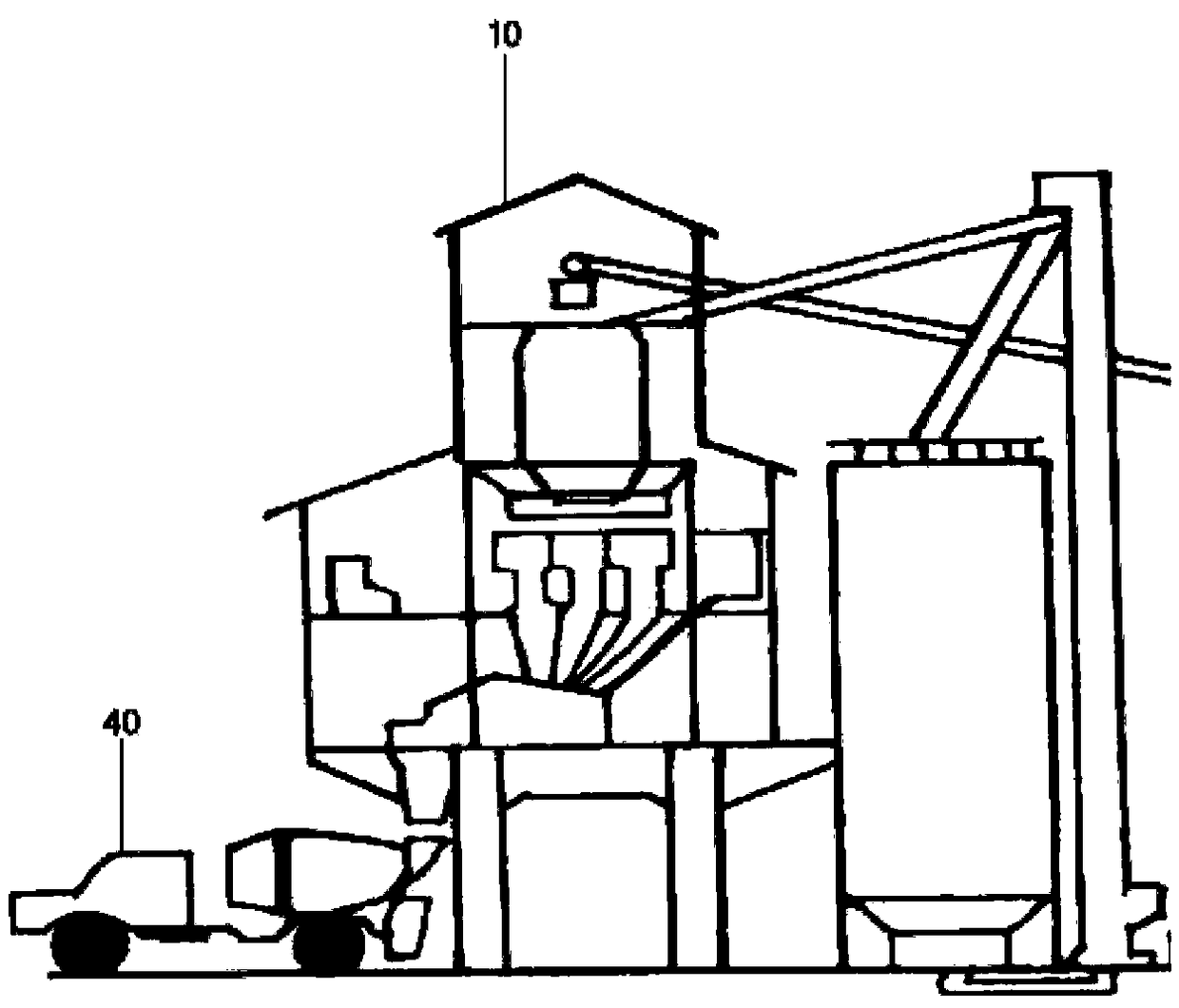

[0041]The integrated slope strengthening method utilizing high-performance sprayed concrete and reinforcing components of the present invention includes: before forming the inner layer part 200, the step of stabilizing the slope 100 by means of reinforcing components 20; mixing water, cement and bone in a prescribed proportion; The step of producing ordinary concrete with a compressive strength of 21-30 MPa and transferring it to the construction site; the ordinary-strength concrete formed by mixing the above-mentioned ordinary concrete, air bubbles and low-grade mixed materials with the help of the mixing unit 60 is discharged to the slope 100 through the spraying guide member 70 , the step of forming the inner layer part 200 with a thickness greater than that of the outer layer part 300; the high performance concrete for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com