Method for preparing pure plant extract deodorant

A technology of plant extracts and deodorants, which is applied in the direction of deodorization, separation methods, chemical instruments and methods, etc., can solve the problems of long preparation time, low removal efficiency, poor applicability of deodorants, etc., and achieve simple production process, The effect of easy application and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

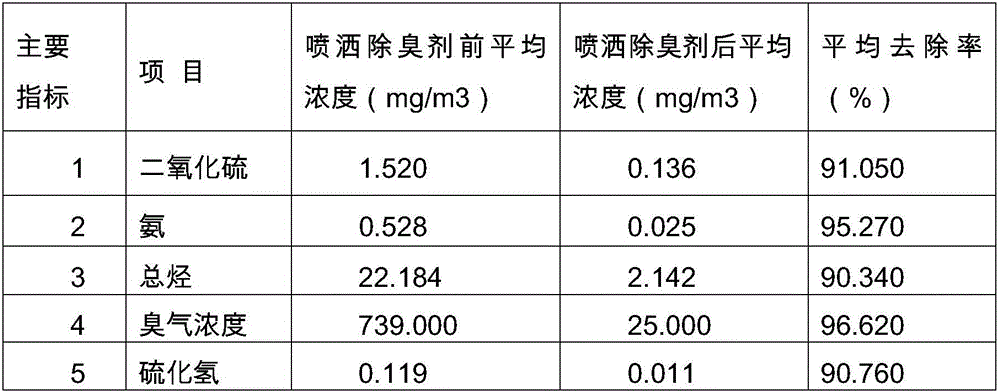

Examples

Embodiment 1

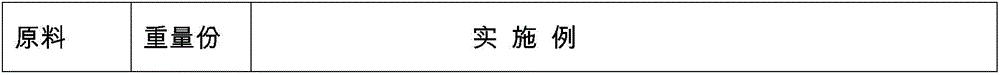

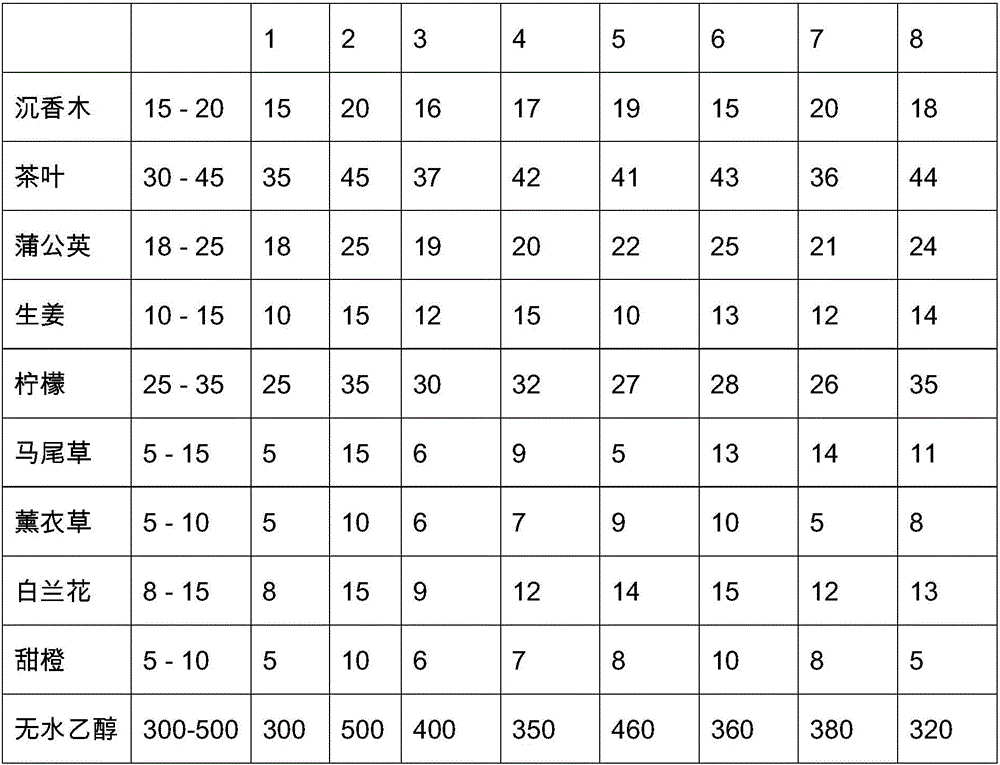

[0018] Embodiment 1 (corresponding raw material and weight ratio value of embodiment 1 in the comparison table 1):

[0019] 15 parts agarwood (Lignum Aquilariae Resinatum), 30 parts tea leaves (Camellia sinensis (L.) O.Ktze.), 18 parts dandelion (Taraxacum platypecidum Diels), 10 parts ginger slices (Zingiberofficinale Rosc.), 25 parts lemon fruit slices (Citrus limon), 5 parts horsetail (Equisetum arvense), 5 parts lavender (Lavandula angustifolia Mill), 8 parts white orchid (Magnolia denudata Desr), 5 parts sweet orange (Citrus sinensis (L.) Osbeck) and 300 parts none Put water and ethanol into the reaction kettle together, cover it after stirring and raise the temperature to 55°C, keep it warm for 1 hour, then raise the temperature to 65°C, keep it warm for 4 hours, and naturally cool down to 45°C. After extraction, the boiled liquid and slag discharged naturally cooled to 45°C were filtered to obtain the liquid, and then distilled under reduced pressure at 45-50°C with a v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com