Nanocellulose/soybean protein composite filter material and preparation method and purposes thereof

A nanocellulose, soybean protein technology, applied in chemical instruments and methods, membrane, membrane technology and other directions, can solve the problems of low functionality, not green environmental protection, low pressure drop, etc., to reduce harm, high filtration efficiency, low pressure drop Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A kind of preparation method of nanocellulose / soybean protein composite filter material of the embodiment of the present invention is " solution processing method ", comprises the following steps:

[0034] Step 1. Prepare soybean protein emulsion; add soybean protein powder with a mass fraction of 1%-15% into deionized water, and stir at room temperature for 20-120 min to form soybean protein emulsion;

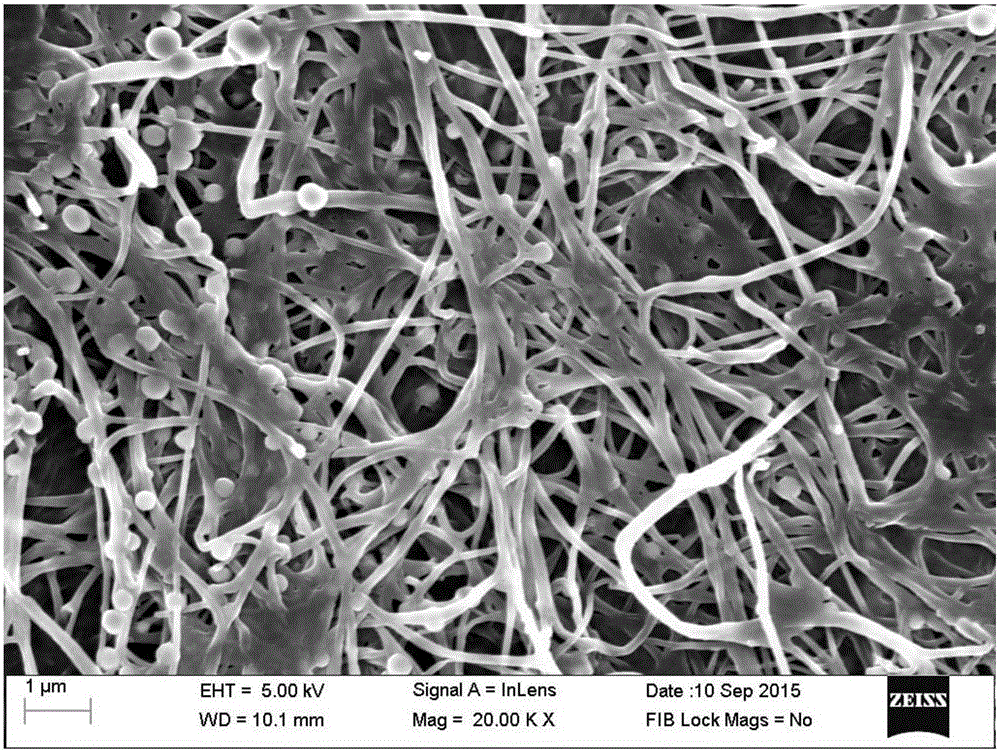

[0035] Step 2, pretreating the nano-bacterial cellulose membrane; washing the nano-bacterial cellulose membrane with clear water to remove the surface medium and impurities; then soaking the nano-bacterial cellulose membrane in 0.02-0.04mol / L NaOH solution, Boil at 90-100°C for 10-500 minutes to remove bacteria and residual medium in the liquid film; rinse with distilled water several times, use pH test paper to lightly press the liquid film to measure the pH value, the pH range is 7.1-7.5, and the nanobacteria are obtained Cellulose membrane; then centrifuge the pretre...

Embodiment 1

[0042] The commercially available bacterial cellulose produced by Acetobacter xylinum was cut into 6×10 cm bacterial cellulose samples.

[0043] Step 1, the preparation of soybean protein solution;

[0044] Weigh a certain amount of soybean protein isolate powder, add deionized water according to the proportion of 5% mass fraction, stir at room temperature for 40 minutes, and perform ultrasonic treatment for 30 minutes;

[0045] Step 2, pretreatment of nanocellulose membrane;

[0046] Take the nano bacterial cellulose (BC) film and cut it into a certain size according to the size of the mold, wash it with water several times to remove the medium and impurities on the surface of the film, then soak the film in 0.02mol / L NaOH solution, cook at 100°C for 100min, remove Bacteria and residual culture medium in the liquid film, the film is milky white and translucent at this time; rinse with distilled water several times, use pH test paper to lightly press the film to measure the p...

Embodiment 2

[0050] Step 1, the preparation of soybean protein solution;

[0051] Weigh a certain amount of soybean protein isolate powder, add deionized water according to the proportion of 10% by mass fraction, and add acrylic acid according to the proportion of 3% by mass fraction, and stir at room temperature for 60 minutes.

[0052] Step 2, pretreatment of nanocellulose membrane;

[0053] Take the nano bacterial cellulose (BC) film and cut it into a certain size according to the size of the mold, wash it with water several times to remove the medium and impurities on the surface of the film, then soak the film in 0.02mol / L NaOH solution, cook at 100°C for 100min, remove Bacteria and residual culture medium in the liquid film, the film is milky white and translucent at this time; rinse with distilled water several times, use pH test paper to lightly press the film to measure the pH value, about 7.1, and obtain the BC film; Break into a slurry state for later use;

[0054] Step 3, pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com