Transparent cubic boron nitride-diamond polycrystal preparation method

A cubic boron nitride and diamond polycrystalline technology, applied in chemical instruments and methods, methods of chemically changing substances by atmospheric pressure, chemical/physical processes, etc. Polycrystalline material hardness, wear resistance, thermal stability, difficult to achieve edge flatness and sharpness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

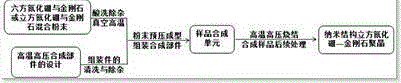

[0026] Select the mixed powder of diamond with an average particle size of 0.1-2μm and hexagonal boron nitride with an average particle size of 0.1-2μm, in which the mass fraction of diamond is 80%, according to figure 1 The process flow chart shown prepares high-performance transparent submicron cubic boron nitride-diamond polycrystalline material. The mixed powder of diamond and cubic boron nitride is first treated in hydrochloric acid with a concentration of 20%-30%. The ratio of the added amount of hydrochloric acid to the mixed micropowder is 2 ml / carat (ml / ct), heated in a water bath at 80°C, and continuously stirred for 36 hours. After the treatment, when the fine powder settles, pour out the liquid, and repeatedly dilute with deionized water until it is close to neutral. After the above acid dissolution and impurity removal process is repeated 3-5 times, the mixed fine powder is settled in a beaker, and the liquid is poured after the settlement is completed, leaving the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com