Room temperature droplet microreactor and method for preparing zirconia gel microspheres

A microreactor and gel microsphere technology, applied in chemical instruments and methods, zirconia, chemical/physical/physicochemical reactors, etc., can solve the problems of easy blockage of channel nozzles, uneven reaction, etc., and achieve uniformity Improved performance and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

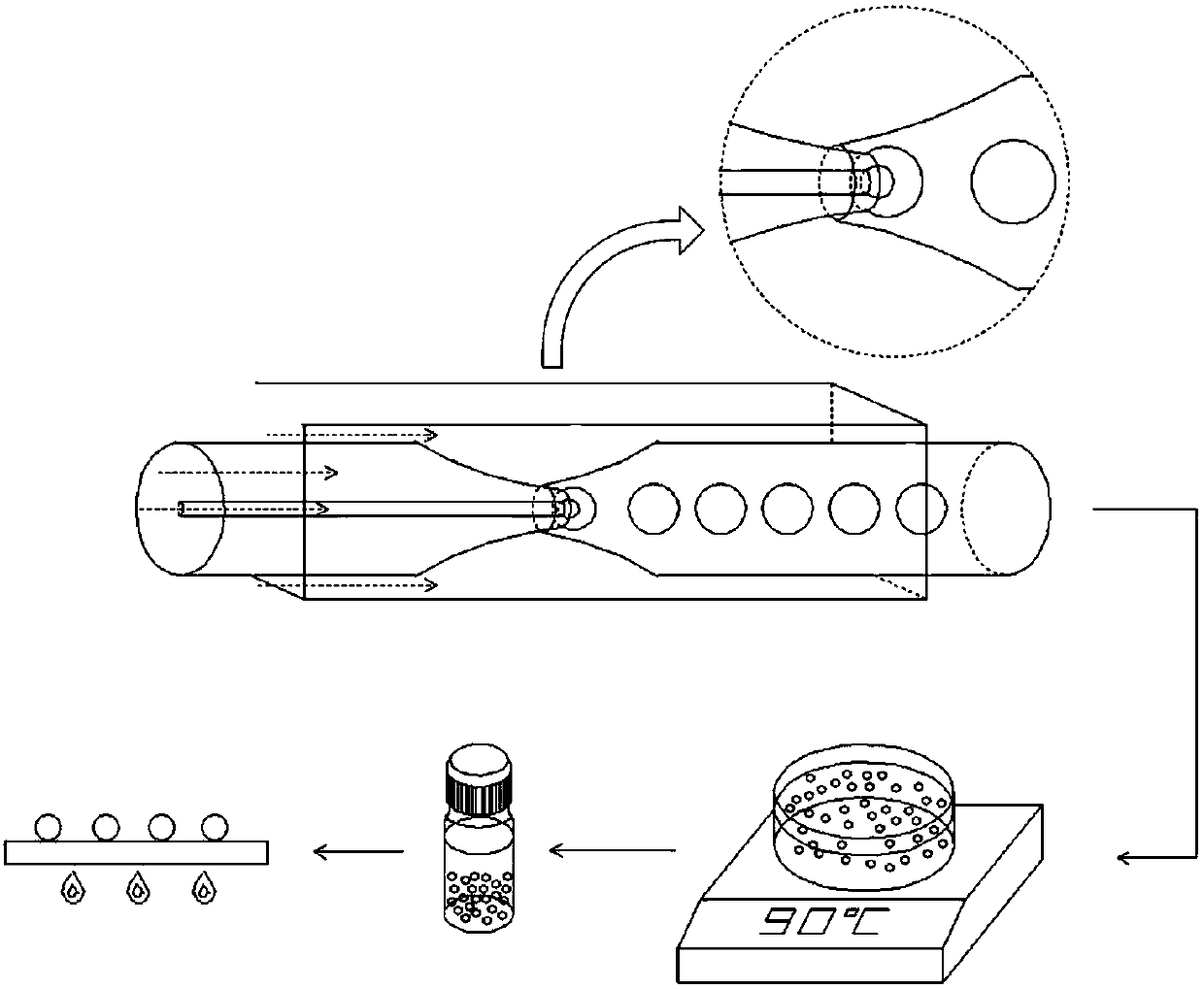

[0100] Example 1: General method

[0101] Using a room temperature droplet microreactor device, the internal phase zirconia precursor sol and the external phase hexamethylenetetramine solution are mixed in the device, and then sheared by the continuous phase silicone oil. The fusion of zirconium sol and the coated form of hexamethylenetetramine solution triggers a gel reaction, and after washing, transparent gel microspheres are obtained. The transparent gel microspheres are sintered at high temperature to obtain zirconia ceramic microspheres. Concrete preparation method comprises the following steps:

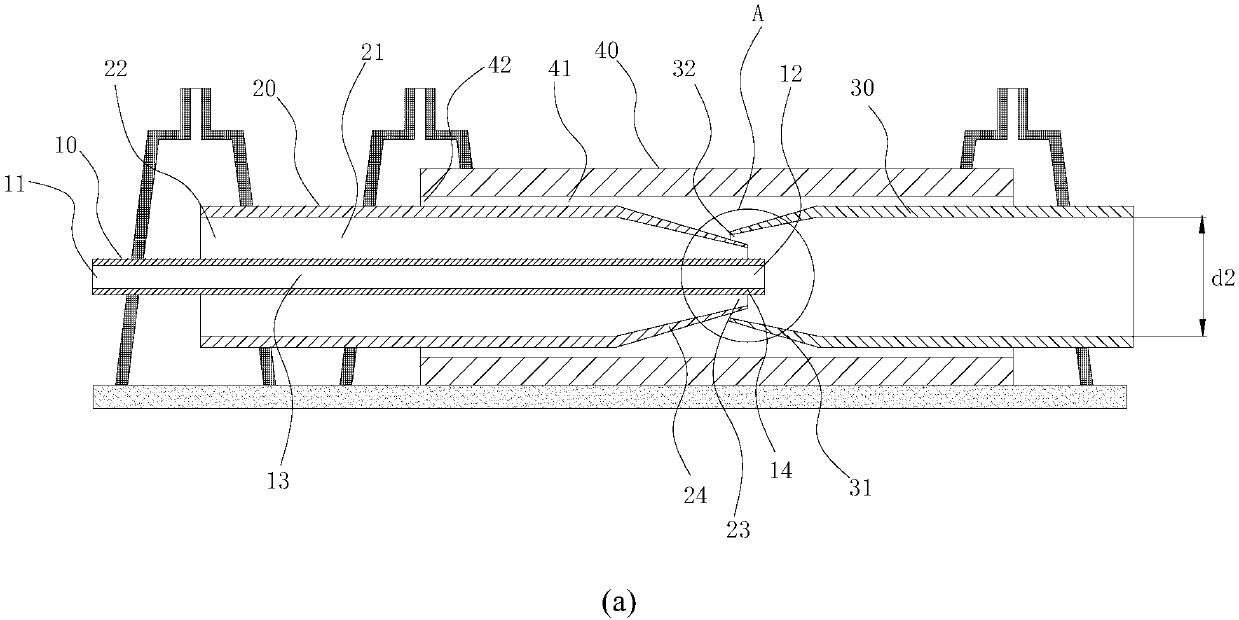

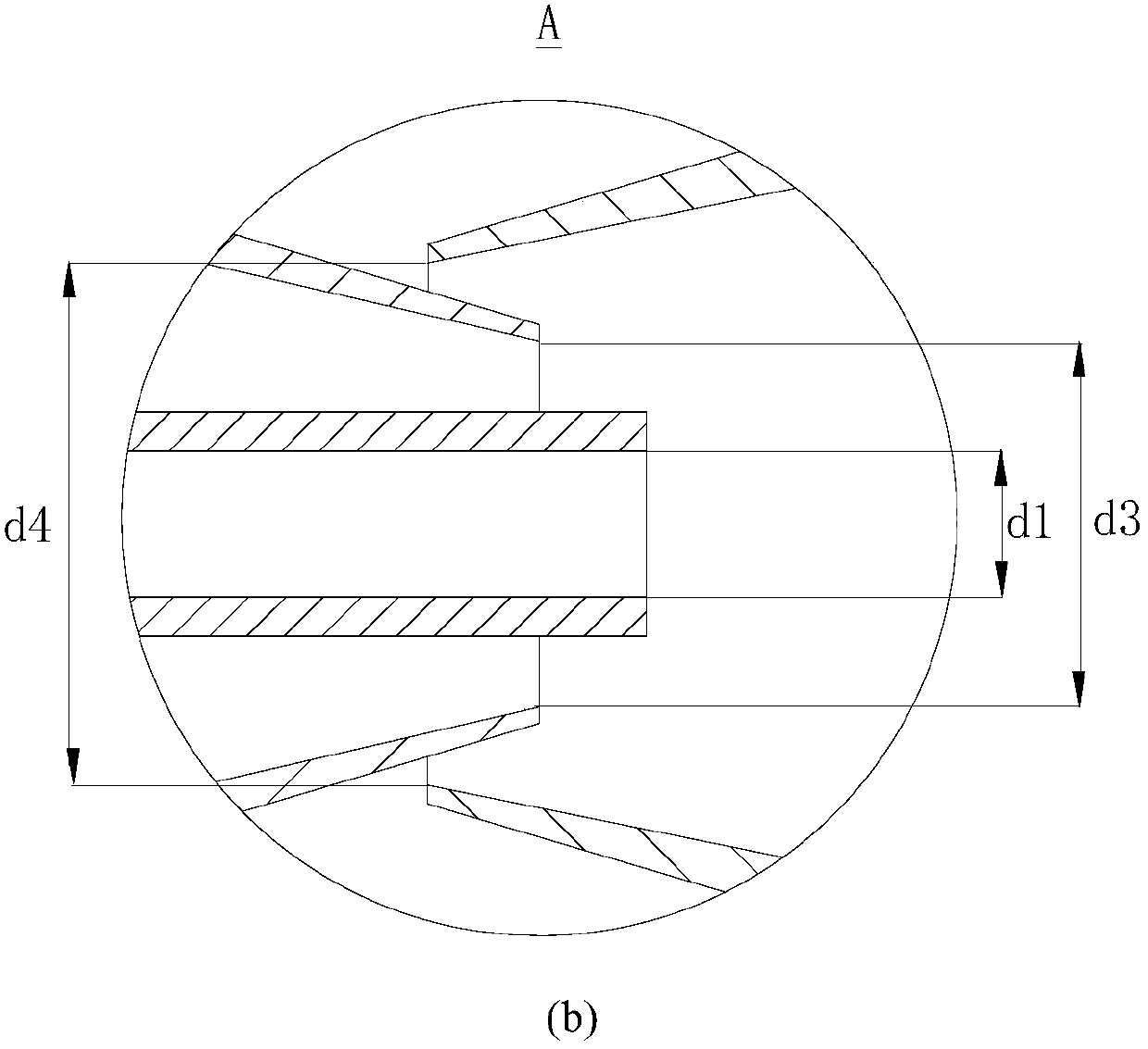

[0102] 1) Prepare the microchannel device: use the glass slide as the substrate, insert the conical incident tube and the conical collecting tube from both ends of the square tube and arrange them coaxially, and assemble them in a nested manner. The thin cylindrical tube and the conical incident tube are in the same direction The conical incident tube is coaxially arranged an...

Embodiment 2

[0110] Embodiment 2: Utilize room temperature droplet microreactor to prepare zirconia gel beads

[0111] Prepare zirconium dioxide precursor sol, hexamethylenetetramine solution, and silicone oil containing 2% Dow Corning 749 according to the method in Example 1, and use them as internal phase fluid, external phase fluid, and continuous phase fluid respectively. Wherein, the zirconium dioxide precursor solution contains zirconyl nitrate and yttrium nitrate, and their molar concentrations are 1.063mol / L and 0.093mol / L respectively; the hexamethylenetetramine solution contains hexamethylenetetramine and urea , and their molar concentration is 3.2mol / L; 2% Dow Corning 749 surfactant is added to the silicone oil according to the volume ratio.

[0112] The zirconia precursor solution, the hexamethylenetetramine solution and the silicone oil containing 2% 749 surfactant were packed into 1ml, 1ml and 10ml syringes respectively and connected to the room temperature droplet microreact...

Embodiment 3

[0115] Example 3: Sintering the zirconia gel beads prepared by the room temperature droplet microreactor

[0116] The 160 μm gel microspheres prepared in Example 2 using the room temperature droplet microreactor were transferred to a crucible, placed in a sintering furnace for sintering, and the sintering process was below 600°C, and the temperature was raised at a rate of 0.5°C per minute , and held at 90°C, 240°C, 320°C, 470°C, and 600°C for 1 hour respectively, between 600°C and 1250°C, the temperature was raised at a rate of 1°C per minute, and kept at 1100°C for 1 hour. 1250°C was kept at the highest temperature for 2 hours, then dropped from 1250°C to 850°C at a rate of 8°C per minute, then naturally cooled to room temperature, and the sintering was completed to obtain zirconia ceramic microspheres with a size of 70 μm ( Figure 4 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap