Environment-friendly water-based varnish for photovoltaic glass glaze and preparation method of environment-friendly water-based varnish

A photovoltaic glass, environmentally friendly technology, applied in the application field of water-based varnish in photovoltaic backplane glass glaze, can solve the problems of high VOCs content, human and environmental hazards, and large varnish odor, and reduce the surface energy, reduce heating time, and increase compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

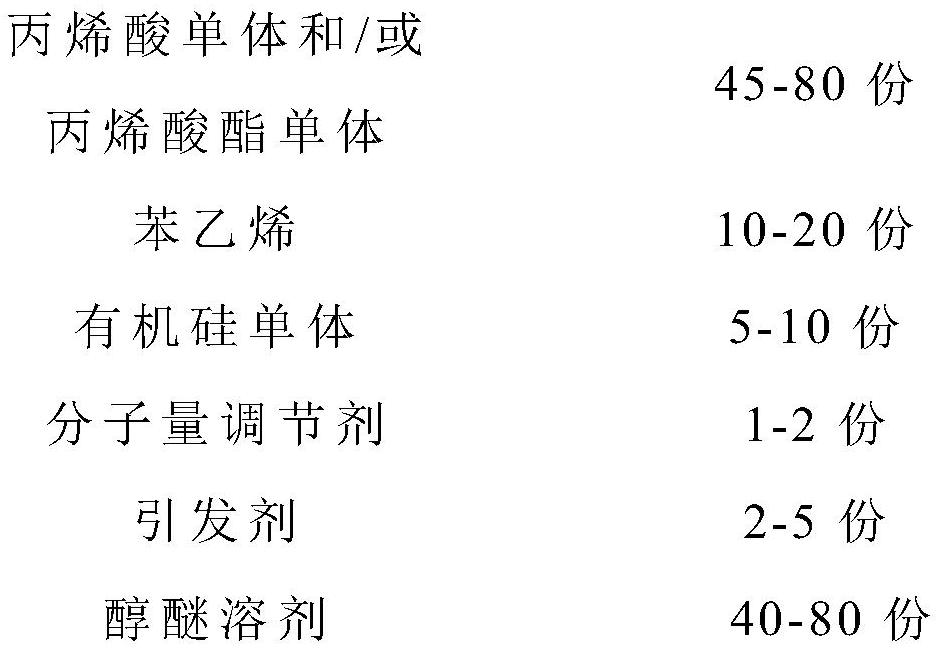

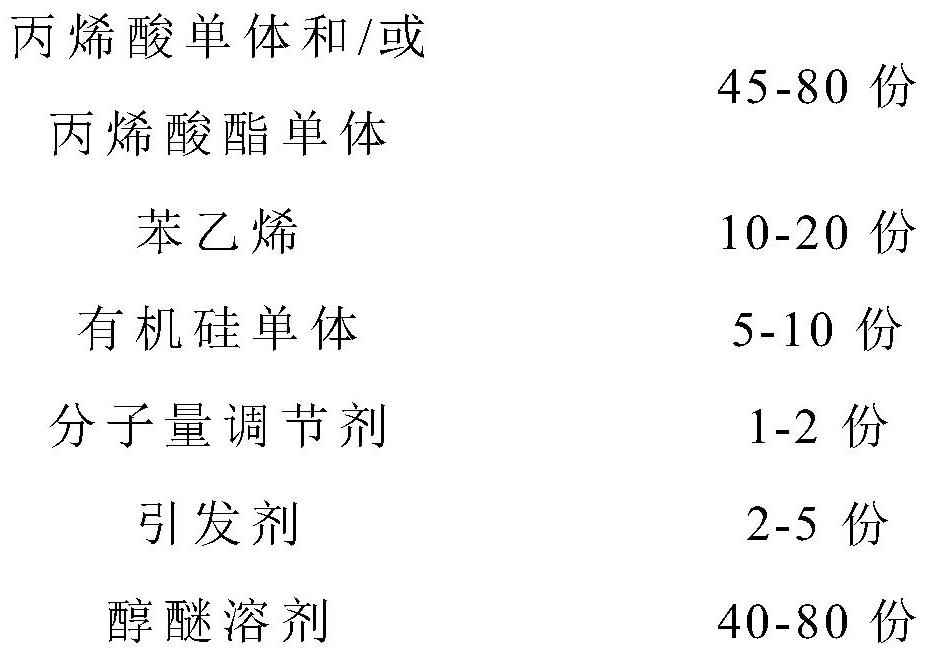

Method used

Image

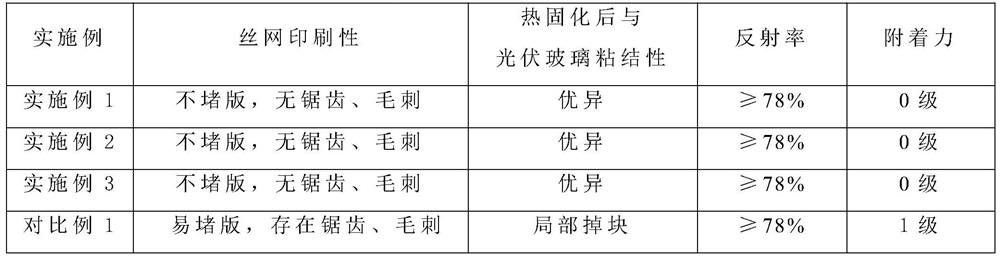

Examples

Embodiment 1

[0040] The preparation of environment-friendly water-based varnish for photovoltaic glass glaze in the present embodiment comprises the following steps:

[0041] (1) Preparation of silicone-modified water-soluble acrylic resin:

[0042] (a) Keep the reactor clean and dry, add 40 parts by weight of alcohol ether solvent, feed nitrogen into the reactor and maintain it, feed cooling water into the condenser, and heat the alcohol ether solvent to 140°C.

[0043] (b) Take another dispersing kettle, add 10 parts of glycidyl tertiary carbonate, 5 parts of hydroxyethyl acrylate, 3 parts of methyl methacrylate, 5 parts of acrylic acid, 10 parts of isobornyl methacrylate in parts by weight , 25 parts of butyl acrylate, 15 parts of styrene, 5 parts of organosilicon monomer, 2 parts of molecular weight regulator (chain transfer agent), 3.5 parts of initiator; stir and mix evenly, the stirring speed is 300r / min, and the stirring time is 40min ; Add the above mixed solution dropwise to the...

Embodiment 2

[0050] The preparation of environment-friendly water-based varnish for photovoltaic glass glaze in the present embodiment comprises the following steps:

[0051] (1) Preparation of silicone-modified water-soluble acrylic resin:

[0052] (a) Keep the reactor clean and dry, add 40 parts by weight of alcohol ether solvent, feed nitrogen into the reactor and keep it, feed cooling water into the condenser, and heat the alcohol ether solvent to 150°C.

[0053] (b) Take another dispersion kettle, add 15 parts of glycidyl tertiary carbonate, 5 parts of hydroxyethyl acrylate, 5 parts of methyl methacrylate, 5 parts of acrylic acid, 5 parts of isobornyl methacrylate in parts by weight , 35 parts of butyl acrylate, 15 parts of styrene, 5 parts of silicone monomer, 1.5 parts of molecular weight regulator (chain transfer agent), 4 parts of initiator; stir and mix evenly, the stirring speed is 300r / min, and the stirring time is 30min ; Add the above mixed solution dropwise to the reaction ...

Embodiment 3

[0060] The preparation of environment-friendly water-based varnish for photovoltaic glass glaze in the present embodiment comprises the following steps:

[0061] (1) Polymerization preparation of silicone modified water-soluble acrylic resin:

[0062] (a) Keep the reactor clean and water-free, add 40 parts by weight of alcohol ether solvent, feed nitrogen into the reactor and maintain, feed cooling water into the condenser, and heat the alcohol ether solvent to 145°C.

[0063] (b) Take another dispersing kettle, add 12 parts of glycidyl tertiary carbonate, 10 parts of hydroxyethyl acrylate, 5 parts of methyl methacrylate, 3 parts of acrylic acid, 10 parts of isobornyl methacrylate in parts by weight , 30 parts of butyl acrylate, 10 parts of styrene, 8 parts of organosilicon monomer, 2 parts of molecular weight regulator (chain transfer agent), 5 parts of initiator; stir and mix evenly, the stirring speed is 300r / min, and the stirring time is 30min ; Add the above mixed soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap