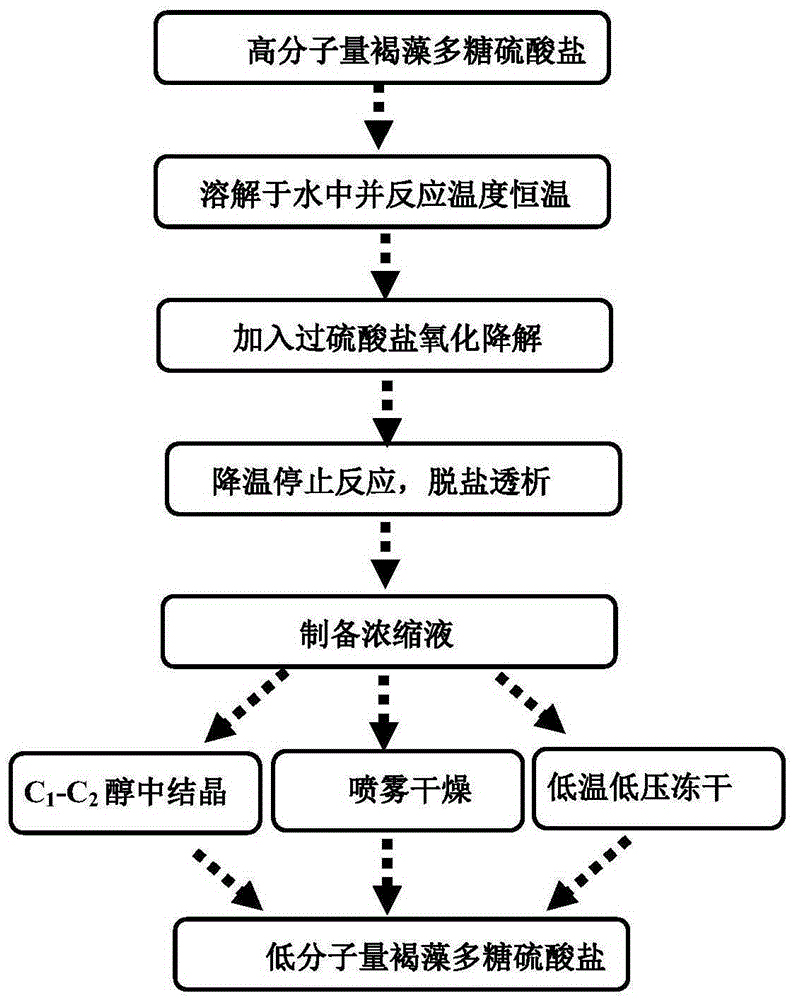

Preparation method of LMWF (Low Molecular Weight Fucoidan)

A technology of fucoidan and low molecular weight, which is applied in the field of preparation of low molecular weight fucoidan sulfate, can solve the problems of cumbersome processing, violent reaction, complex equipment and process, etc., and achieve the effect of simple process, simple follow-up treatment and no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1, the impact of different temperatures on the degradation of fucoidan sulfate

[0022] Take fucoidan sulfate with a weight average molecular weight of 240-2400kDa, add distilled aqueous solution to prepare 6 parts of fucoidan sulfate solution with a mass concentration of 1%, and keep the temperature at 50°C, 60°C, 70°C, 80°C, and 90°C respectively , 100°C. Put 6 parts of the solution into the reactor respectively, add concentrated persulfate solution, control the concentration of persulfate to 100mM, stir rapidly to carry out the degradation reaction, cool down after 60min to stop the reaction, and dialyze the obtained solution with a cut-off molecular weight of 2000Da After bag dialysis and desalination, concentrate the dialysate, add absolute ethanol to a final concentration of 75-80%, let it stand for more than 12 hours, filter, and vacuum-dry the obtained solid to obtain low molecular weight fucoidan sulfate. It can be seen from Table 1 that temperature...

Embodiment 2

[0025] Embodiment 2, the influence of different reaction time solution fucoidan sulfate ester

[0026] Take fucoidan sulfate with a weight average molecular weight of 240-2400kDa, add distilled aqueous solution to prepare 4 parts of fucoidan sulfate solution with a mass concentration of 1%, and keep the temperature at 100°C. Put the 4 solutions into the reactor respectively, add concentrated persulfate solution, control the concentration of persulfate to 100mM, stir rapidly to carry out the degradation reaction, cool down after 10min, 30min, 60min, and 120min respectively to stop the reaction, and the obtained After dialysis and desalination of the solution with a dialysis bag with a cut-off molecular weight of 2000Da, after concentrating the dialysate, add absolute ethanol to a final concentration of 75-80% and let it stand for 12 hours, filter it with suction, and dry the obtained solid in vacuum to obtain a low molecular weight Fucoidan Sulfate. It can be seen from Table 2...

Embodiment 3

[0029] Embodiment 3, the impact of different persulfate concentrations on microwave degradation of fucoidan sulfate

[0030] Take fucoidan sulfate with a weight average molecular weight of 240-2400kDa, add distilled aqueous solution to prepare 7 parts of fucoidan sulfate solution with a mass concentration of 1%, keep the temperature at 100°C, add concentrated persulfate solution respectively, and control persulfate Concentrations were 10mM, 20mM, 50mM, 100mM, 200mM, 500mM, 1000mM, and the degradation reaction was carried out by rapid stirring. After 60 minutes, the temperature was lowered to stop the reaction. The concentrated solution is spray-dried to obtain low molecular weight fucoidan sulfate ester. It can be seen from Table 3 that the concentration of persulfate has a great influence on the degradation of fucoidan sulfate. Generally, the higher the concentration, the better the degradation effect. However, when the concentration is too high, over-oxidation often occurs. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap