High-efficiency modification method of sulfonic acid resin catalyst

A high-efficiency sulfonic acid, catalyst technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve problems such as being unsuitable for large-scale production, difficult to prepare methyl chloroacetate and sodium methoxide, and the like, Achieving the effect of good reactivity and extreme reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

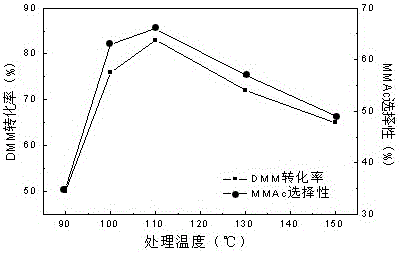

Embodiment 1

[0038] The mass of 10 grams of D-009B sulfonic acid tree catalyst was charged into 100 mL containing non-alcoholic solvents (methanol, ethanol, propanol, ethylene glycol, 1,3-propanediol, 2-propanol, n-butanol, n-pentanol). , isoamyl alcohol, n-hexanol, cyclohexanol, benzyl alcohol, etc.), the sulfonic acid resin catalyst was treated in the temperature range of 65-150 °C for 1-7 h. The treated catalyst was filtered and dried in an oven at 120 °C for 6 h. The evaluation conditions of the catalyst were as follows: weigh 30 mL of DMM, 30 mL of 1,4-dioxane solvent, and 1 g of the modified sulfonic acid resin catalyst, respectively, and put them into the reaction kettle. 2 The air in the kettle was replaced three times under the condition of 1.0 MPa, so that the remaining air content in the kettle was less than 0.1 %, 3.0 MPa CO was introduced, and it was allowed to stand for 30 min for leak detection of the reaction kettle, and the device was emptied after ensuring that there was ...

Embodiment 2

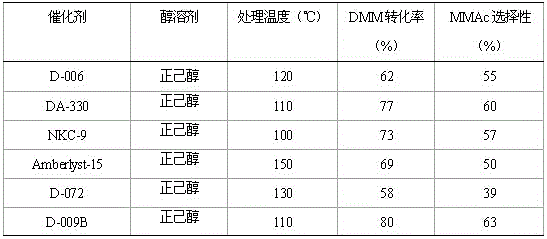

[0043] 10 grams of different models of polystyrene sulfonic acid resin catalysts (D-009B, DA-330, D-006, D-072, Amberlyst-15, NKC-9) were loaded into a 100 mL reaction kettle containing n-hexanol solvent, Treated at 100-150 °C, 3.0 MPa, CO atmosphere for 6 h. The treated catalyst was filtered and dried in an oven at 120 °C for 6 h. The evaluation conditions of the catalyst were as follows: weigh 30 mL of DMM, 30 mL of 1,4-dioxane solvent, and 1 g of the modified sulfonic acid resin catalyst, respectively, and put them into the reaction kettle. 2 The air in the kettle was replaced three times under the condition of 1.0 MPa, so that the remaining air content in the kettle was less than 0.1 %, 3.0 MPa CO was introduced, and it was allowed to stand for 30 min for leak detection of the reaction kettle, and the device was emptied after ensuring that there was no air leakage. gas in the kettle. The stirring speed of the reaction kettle was 500 rpm, 3.0 MPa CO was introduced, and th...

Embodiment 3

[0048] Put 10 grams of D-009B catalyst into a 100 mL reaction kettle containing n-hexanol solvent, and treat at 110 °C, 3.0 MPa, and CO atmosphere for 0.5-20 h. The treated catalyst was filtered and dried in an oven at 120 °C for 6 h. The evaluation conditions of the catalyst were as follows: weigh 30 mL of DMM, 30 mL of 1,4-dioxane solvent, and 1 g of the modified sulfonic acid resin catalyst, respectively, and put them into the reaction kettle. 2 The air in the kettle was replaced three times under the condition of 1.0 MPa, so that the remaining air content in the kettle was less than 0.1 %, 3.0 MPa CO was introduced, and it was allowed to stand for 30 min for leak detection of the reaction kettle, and the device was emptied after ensuring that there was no air leakage. gas in the kettle. The stirring speed of the reaction kettle was 500 rpm, 3.0 MPa CO was introduced, and the reaction temperature was controlled to be 110 °C, and the reaction was carried out for 6 hours. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com