Ore dressing method for low grade nickel sulphide ore

A technology of nickel sulfide ore and beneficiation method, applied in flotation, solid separation, etc., can solve problems such as corrosion of flotation equipment and limited application, and achieve the effect of eliminating heterogeneous coagulation, eliminating corrosion, and improving high-efficiency separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

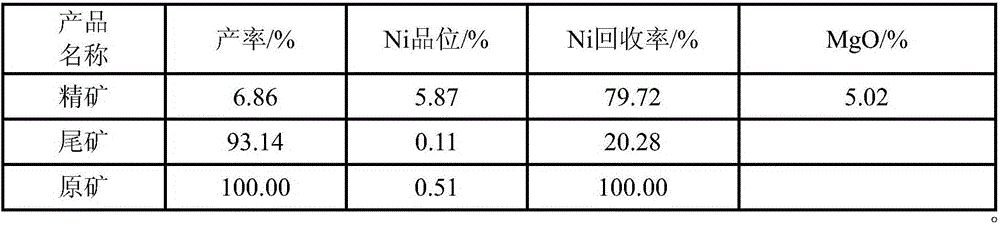

Embodiment 1

[0016] (1) Grinding low-grade nickel sulfide ore to -74 μm particle size grade accounts for 72% of the total ore mass percentage;

[0017] (2) Add sulfuric acid to the ground pulp to reduce the pH of the pulp to 5.5, then add ethylenediaminetetraacetic acid 6kg / t ore, and mix the pulp for 20 minutes. During the pulp mixing process, add sulfuric acid to keep the pH of the pulp at 5.5;

[0018] (3) Add pH adjusting agent sodium carbonate to adjust the pulp pH to 9, add the xanthan gum of 150g / t ore, the Y89 xanthate of 120g / t ore, the No. 2 oil of 20g / t ore, and obtain to step (2) The ore slurry is used for roughing to obtain nickel sulfide ore roughing concentrate and roughing tailings, and Y89 xanthate is added to the roughing tailings for two sweeps to obtain the final tailings and sweeping ore. The first sweeping The dosage of collector Y89 xanthate is 60g / ton of ore, and the dosage of collector Y89 xanthate in the second sweep is 30g / ton of ore. Return to the first sweep; ...

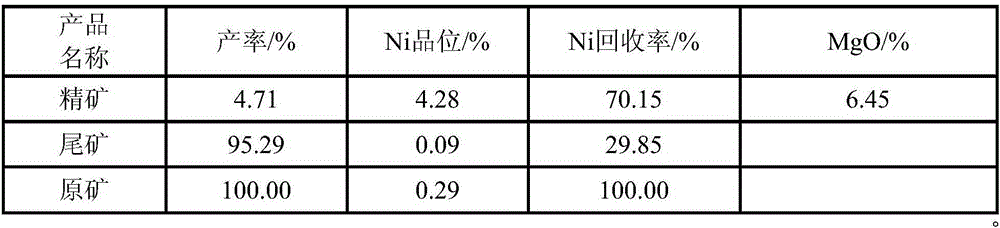

Embodiment 2

[0024] (1) Grinding low-grade nickel sulfide ore to -74 μm particle size grade accounts for 70% of the total ore mass percentage.

[0025] (2) Add sulfuric acid to the ground pulp to reduce the pH of the pulp to 5.8, then add 8kg / t of ethylenediaminetetraacetic acid ore, and adjust the pulp for 20 minutes. During the pulping process, add sulfuric acid to keep the pH of the pulp at 5.8.

[0026] (3) Add pH adjusting agent sodium carbonate to adjust the pulp pH to 9, add the xanthan gum of 200g / t ore, the Y89 xanthate of 180g / t ore, No. 2 oil of 25g / t ore, and obtain to step (2) The ore slurry is used for roughing to obtain nickel sulfide ore roughing concentrate and roughing tailings, and Y89 xanthate is added to the roughing tailings for two sweeps to obtain the final tailings and sweeping ore. The first sweeping The dosage of collector Y89 xanthate is 90g / ton of ore, and the dosage of collector Y89 xanthate in the second sweep is 50g / ton of ore. Return to the first sweep.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com