Aviation kerosene storage tank capable of preventing microorganism breeding

A technology for microorganisms and aviation fuel, applied in the field of storage tanks, can solve the problems affecting the quality of aviation fuel, long time, and large storage tank volume, and achieve the effects of preventing the growth of aviation fuel microorganisms, setting reasonable locations, and high safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

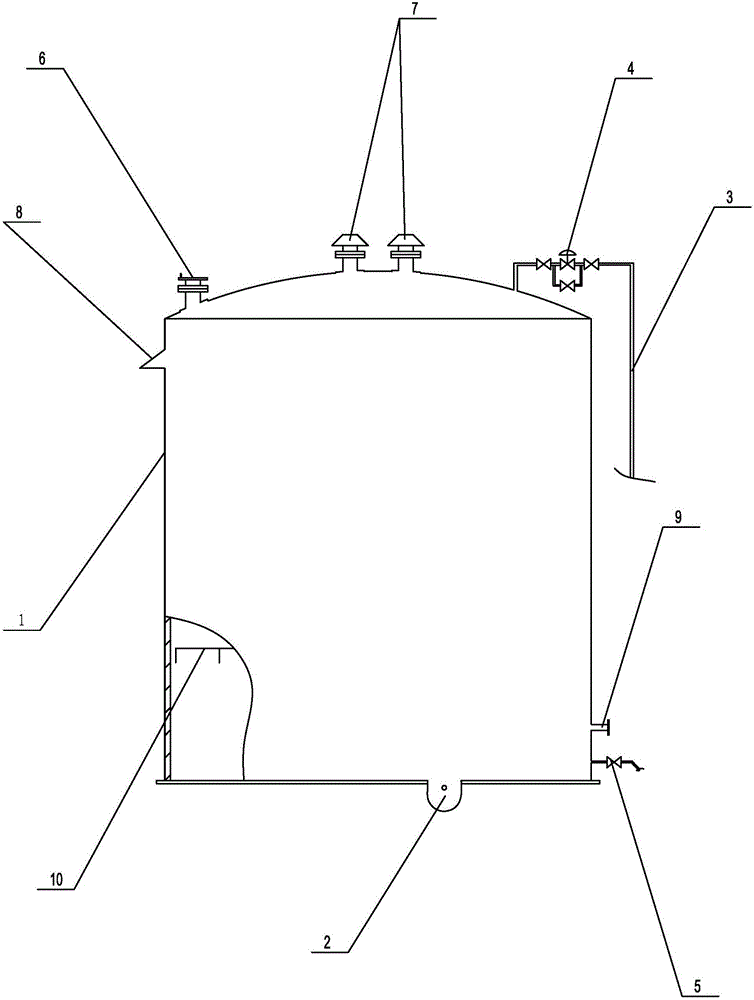

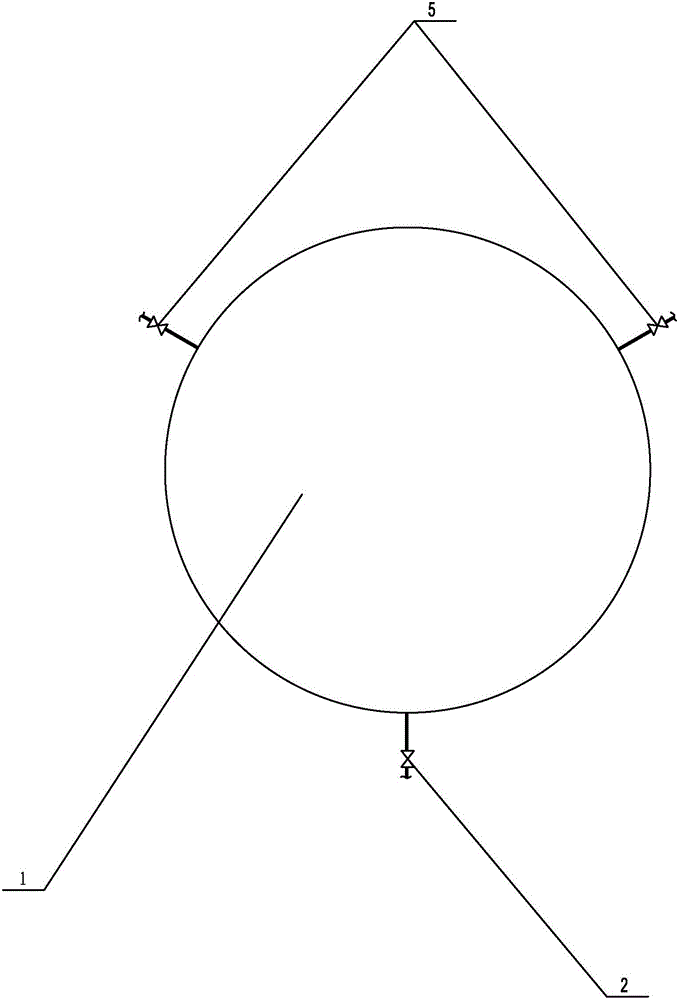

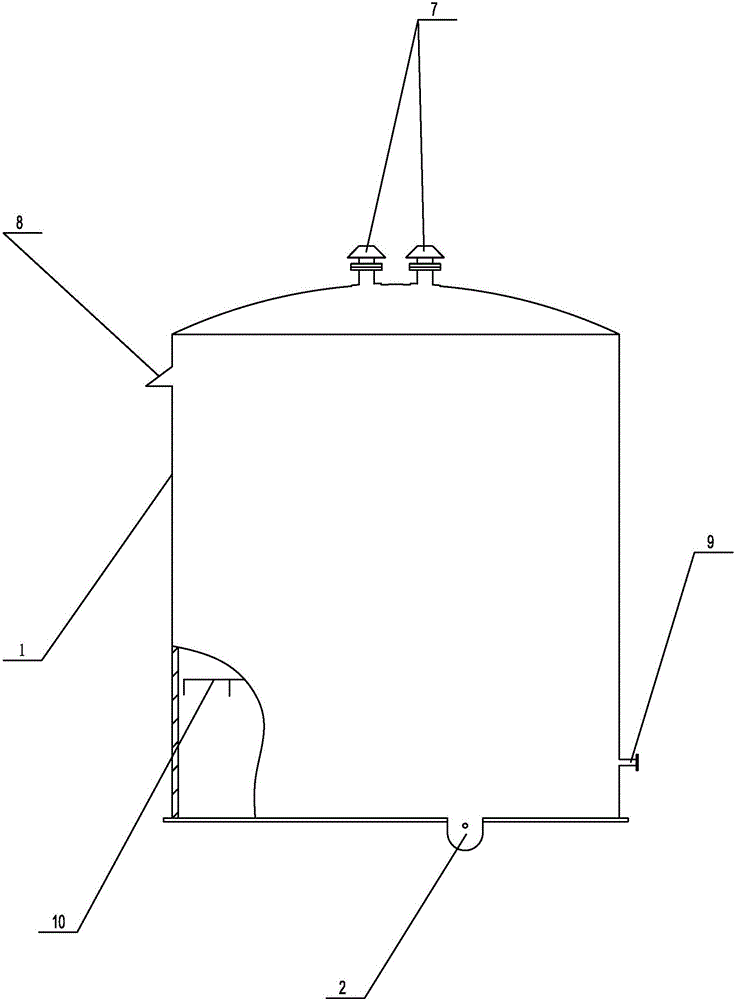

[0021] The invention discloses a storage tank capable of preventing the growth of microorganisms, which is mainly used for storing jet fuel, and can also be used for storing liquids with the same high requirements and standards as jet fuel. like figure 1 and figure 2 Propose a kind of specific embodiment of the present invention as shown, comprise tank body 1, the top middle end of described tank body 1 is provided with two breather valves 7, and the outer wall upper end of described tank body 1 is provided with the ventilation hole 8 that communicates with atmosphere , the lower end and near the bottom of the tank is provided with a pumping outlet 9, the tank body 1 is provided with a floating plate 10, the bottom of the tank body 1 and near the pumping port 9 is provided with an automatic water cutter 2, the tank body 1 The top of the nitrogen pipe 3 is provided with a nitrogen pipe 3, and the other end of the nitrogen pipe 3 is connected to a nitrogen supply device, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com