Graphene dispersion method, graphene dispersion system and its preparation method and application

A graphene dispersion liquid and graphene technology, applied in graphene dispersion, graphene dispersion system and its preparation and application fields, can solve problems such as agglomeration, uneven dispersion of composite materials, poor graphene dispersion, etc. Compatibility issues, good dilution and the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

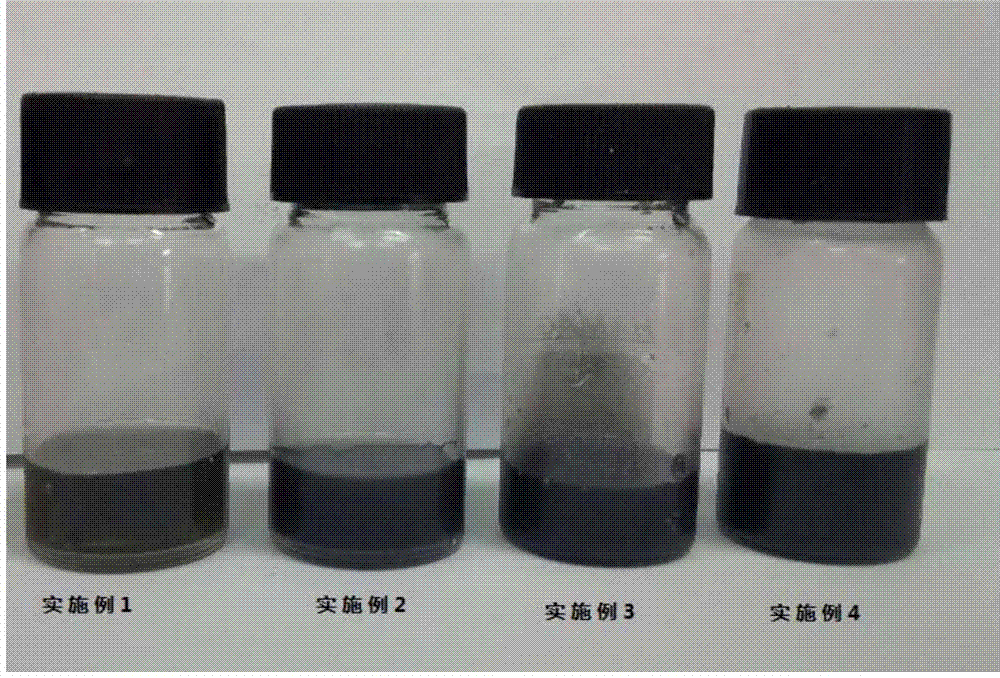

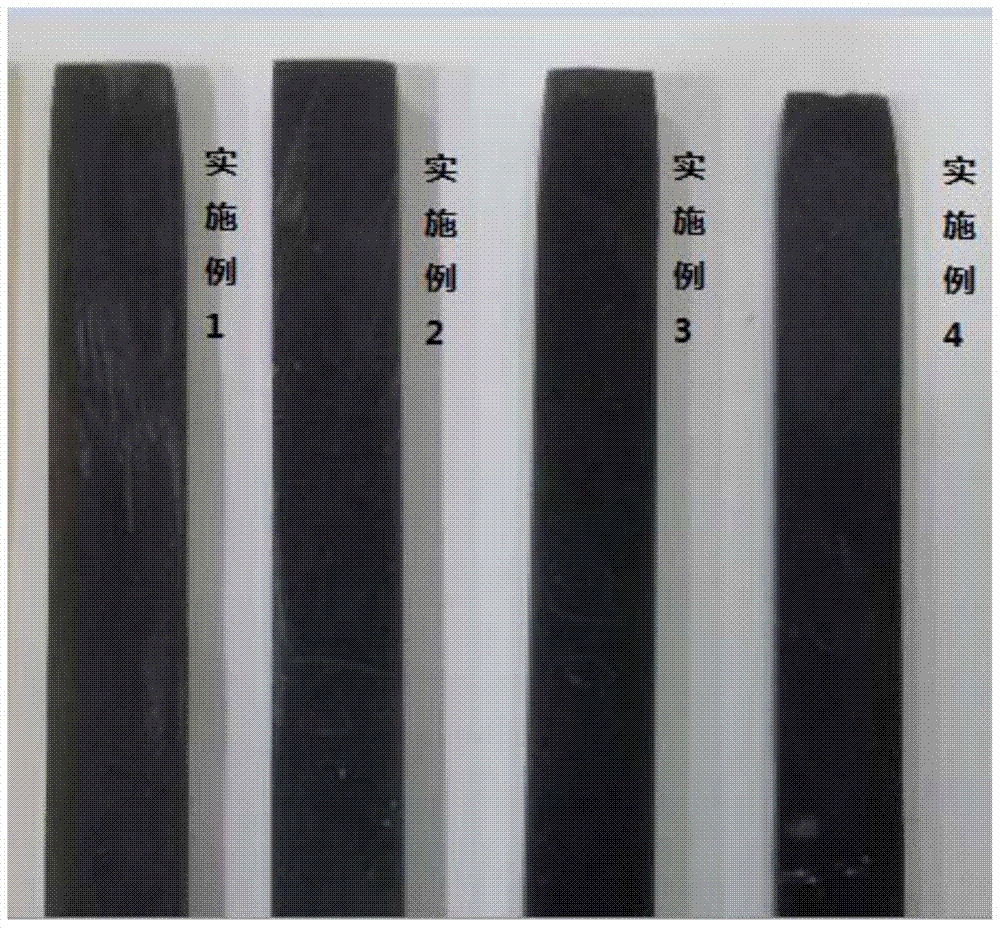

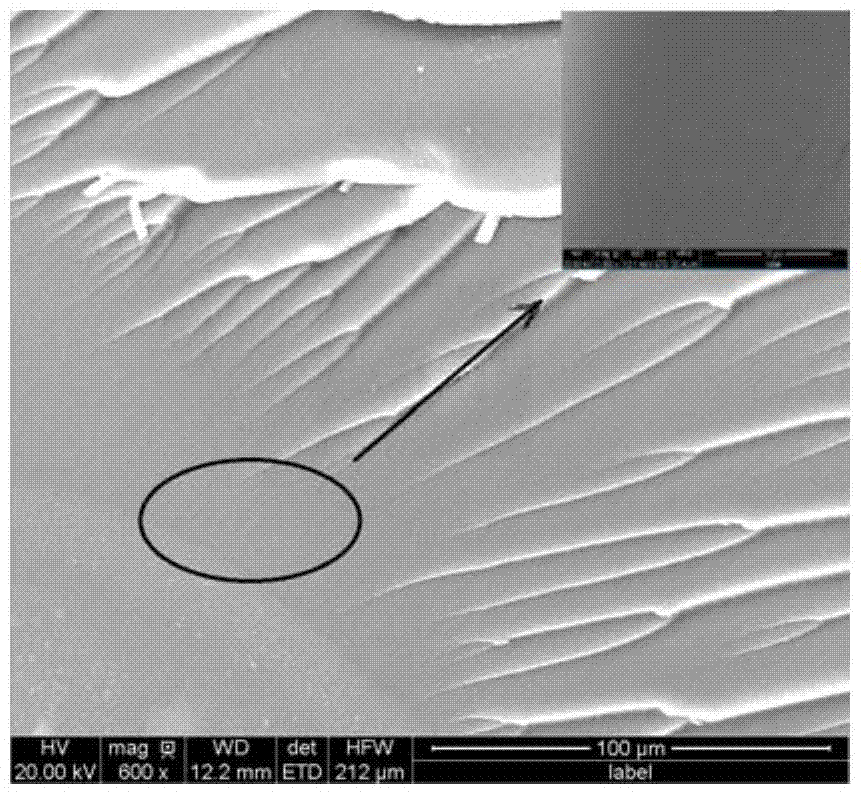

[0042] Embodiment 1: The graphene that takes 0.0075g and 1.5g epoxycyclopentane are uniformly mixed, and the epoxy diluent-graphene mixture that makes is mixed with 15g epoxy resin, mechanically stirred for 5 minutes, added 12g Low-molecular polyamide 650 curing agent, and cured at 70 ° C for 4 hours, and then cured at room temperature for 72 hours to obtain a cured graphene-epoxy resin composite material. see Figure 1-2 The morphology of the graphene-epoxy composite before and after curing is shown. see again Figure 3a-Figure 3b , it can be seen that graphene is uniformly dispersed in the composite material.

Embodiment 2

[0043] Embodiment 2: Take by weighing 0.015g graphene and 1.5g epoxycyclopentane, mix evenly, the epoxy diluent-graphene mixture that makes is mixed with 15g epoxy resin, mechanically stirs 10 minutes, adds 12g low-molecular polyamide 650, and cured at 70°C for 4 hours, and then cured at room temperature for 72 hours to obtain a cured graphene-epoxy composite material. see Figure 1-2 The morphology of the graphene-epoxy composite before and after curing is shown. Likewise, graphene is uniformly dispersed in the composite material.

Embodiment 3

[0044]Embodiment 3: Take by weighing 0.0225g graphene and 1.5g epoxycyclopentane, mix evenly, the epoxy diluent-graphene mixture that makes is mixed with 15g epoxy resin, mechanically stirs 10 minutes, adds 12g low-molecular polyamide 650, and cured at 70°C for 4 hours, and then cured at room temperature for 72 hours to obtain a cured graphene-epoxy composite material. see Figure 1-2 The morphology of the graphene-epoxy composite before and after curing is shown. Likewise, graphene is uniformly dispersed in the composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com