Geothermal pipe repairing agent and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

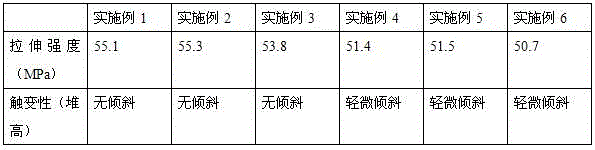

Examples

Embodiment 1

[0039] A repairing agent for floor heating pipes, comprising A component and B component, A component comprising the following components in parts by mass:

[0040] 90 parts of epoxy resin,

[0041] 15 parts of unsaturated polyester resin,

[0042] 2 parts cellulose ether,

[0043] 0.8 parts of polyvinyl alcohol,

[0044] Attapulgite 1.5 parts,

[0045] 0.6 part of alkylphenol polyoxyethylene ether,

[0046] 12 parts of stuffing;

[0047] B component is curing agent;

[0048] The mass mixing ratio of A component and B component is 100:4.

[0049] Wherein, the epoxy resin is bisphenol A type epoxy resin, and its epoxy value is 0.42-0.45mol / 100g.

[0050] The filler is white carbon black and aluminum powder, the mass ratio of the two is 1:1.

[0051] The curing agent is a mixture of low-molecular polyamide curing agent and polyetheramine curing agent, and the mass ratio of the two is 2:1.

[0052] The preparation method of described floor heating pipe restoration agent,...

Embodiment 2

[0059] A repairing agent for floor heating pipes, comprising A component and B component, A component comprising the following components in parts by mass:

[0060] 80 parts of epoxy resin,

[0061] 10 parts of unsaturated polyester resin,

[0062] 1 part cellulose ether,

[0063] 1 part polyvinyl alcohol,

[0064] Attapulgite 1 part,

[0065] 0.5 part of alkylphenol polyoxyethylene ether,

[0066] Filling 10 parts;

[0067] B component is curing agent;

[0068] The mass mixing ratio of A component and B component is 100:3.

[0069] Wherein, the epoxy resin is bisphenol A type epoxy resin, and its epoxy value is 0.42-0.45mol / 100g.

[0070] The filler is preferably white carbon black and aluminum powder, and the mass ratio of the two is 1:2.

[0071] The curing agent is a mixture of low-molecular polyamide curing agent and polyetheramine curing agent, and the mass ratio of the two is 3:1.

[0072] The preparation method of described floor heating pipe restoration agent...

Embodiment 3

[0079] A repairing agent for floor heating pipes, comprising A component and B component, A component comprising the following components in parts by mass:

[0080] 100 parts of epoxy resin,

[0081] 20 parts of unsaturated polyester resin,

[0082] 3 parts cellulose ether,

[0083] 0.5 parts of polyvinyl alcohol,

[0084] Attapulgite 2 parts,

[0085] 1 part of alkylphenol polyoxyethylene ether,

[0086] 18 parts of stuffing;

[0087] B component is curing agent;

[0088] The mass mixing ratio of A component and B component is 100:5.

[0089] Wherein, the epoxy resin is bisphenol A type epoxy resin, and its epoxy value is 0.42-0.45mol / 100g.

[0090] The filler is preferably white carbon black and aluminum powder, and the mass ratio of the two is 3:2.

[0091] The curing agent is a mixture of low-molecular polyamide curing agent and polyetheramine curing agent, and the mass ratio of the two is 2:1.

[0092] The preparation method of described floor heating pipe restor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com