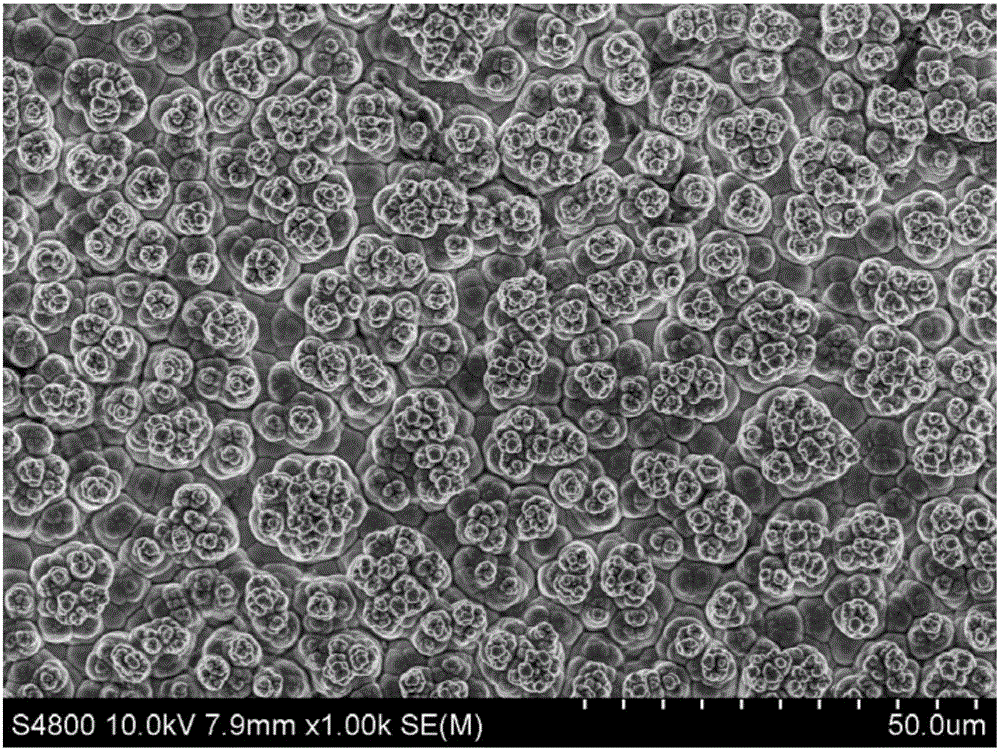

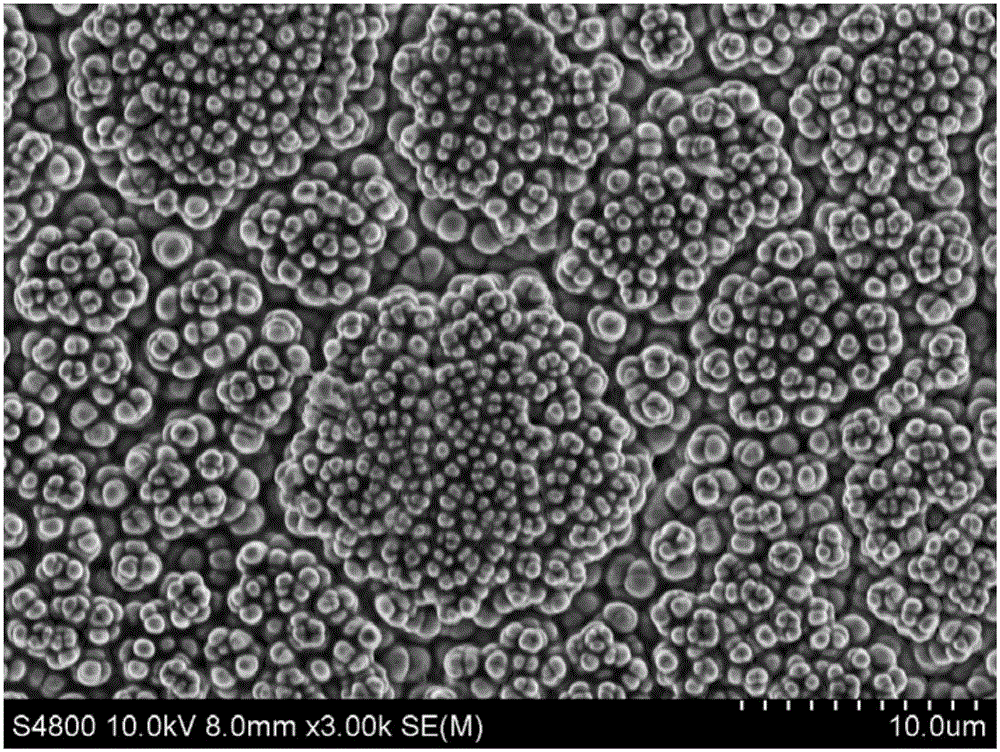

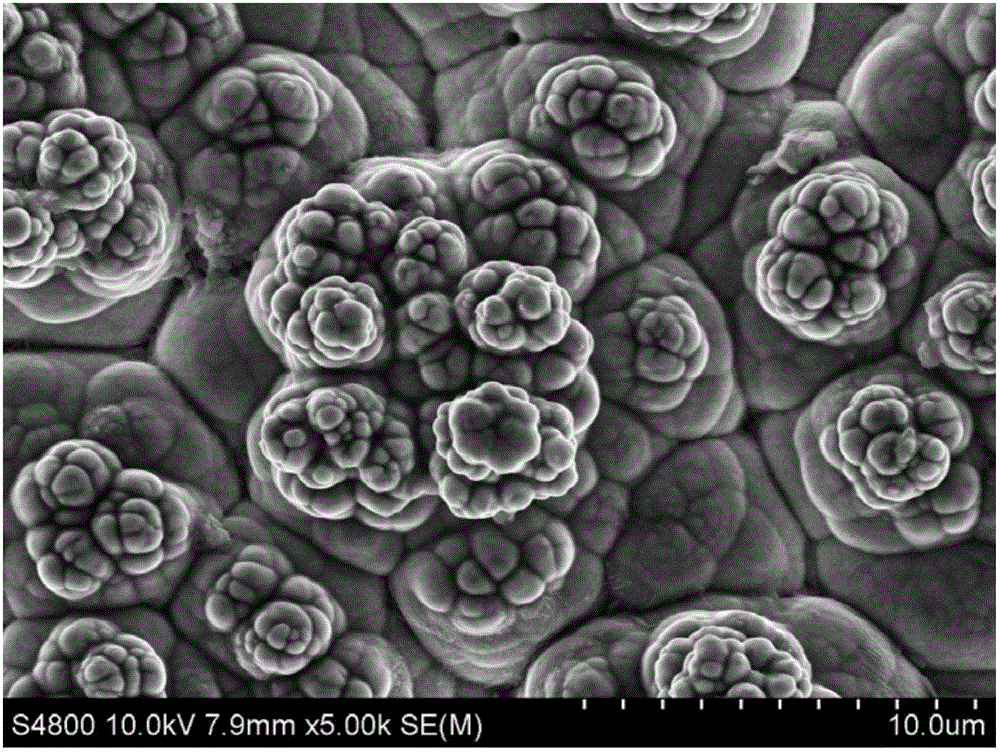

Ce-Ni-B/GO chemical composite deposition layer and ultrasonic-assisted preparation method thereof

A deposition layer and ultrasonic technology, applied in the field of Ce-Ni-B/GO chemical composite deposition layer and its ultrasonic-assisted preparation, can solve the problems of corrosion resistance, friction resistance and low hardness, and increase the brightness and wear resistance of the coating Reinforcement, hardness and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of Ce-Ni-B / GO composite deposition solution, calculated by every liter of solution, its composition and content are as follows:

[0025] Ce 0.1g

[0026] Nickel chloride hexahydrate 20g

[0027] Sodium borohydride 0.5g

[0029] Ethylenediamine 30g

[0030] Sodium lauryl sulfate 0.2g

[0032] The balance is water.

[0033] Add cerium, nickel chloride hexahydrate, sodium borohydride, sodium hydroxide, ethylenediamine, and sodium lauryl sulfate to distilled water to dissolve in turn, and then add surface-modified graphene oxide GO to the above deposition solution , and finally adjust the pH value to 14 to obtain the Ce-Ni-B / GO composite deposition solution.

Embodiment 2

[0035] Apply the multifunctional chemical composite deposition solution obtained in Example 1 to the surface of low carbon steel to form a Ce-Ni-B / GO multifunctional chemical composite deposition layer, specifically comprising the following steps:

[0036] (1) Pretreatment of the surface of the carbon steel workpiece. The surface of the low carbon steel workpiece is polished and decontaminated by 01#, 02# and 03 sandpaper in turn, and then degreased with acetone in an ultrasonic cleaner for 60s, and rinsed with deionized water for 1min ; Then pickle with 20% hydrochloric acid for 30 seconds, rinse with deionized water for 1 min; finally activate with 5% hydrochloric acid for 15 seconds, rinse with deionized water for 1 min;

[0037] (2), put the pretreated carbon steel workpiece in step (1) into the Ce-Ni-B / GO chemical composite deposition solution, the solution temperature is controlled at 85°C, the rotating speed is 200r / min, and the ultrasonic intensity is 200W. The ultraso...

Embodiment 3

[0039] A kind of Ce-Ni-B / GO composite deposition liquid, calculated by every liter of deposition liquid, its composition and content are as follows:

[0040] Ce 1g,

[0041] Nickel chloride hexahydrate 30g

[0042] Sodium borohydride 1g

[0043] Sodium hydroxide 30g

[0044] Ethylenediamine 30g

[0045] Sodium lauryl sulfate 0.2g

[0047] The balance is distilled water.

[0048]Add cerium, nickel chloride hexahydrate, sodium borohydride, sodium hydroxide, ethylenediamine, and sodium lauryl sulfate to distilled water in order to dissolve, then add surface-modified graphene oxide GO, and finally adjust the pH with ammonia water When the value reaches 14, the Ce-Ni-B / GO composite deposition solution is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com