Electric-hydraulic control type subsoiler

An electro-hydraulic control and subsoiler technology, applied in mechanical equipment, soil loosening devices, agricultural machinery and implements, etc., can solve the problems of inconsistent tillage depth, large working resistance, and high energy consumption, and reduce tillage resistance. , to ensure consistency, the effect of convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

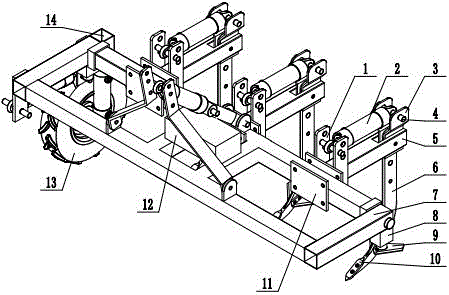

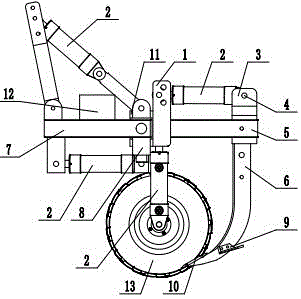

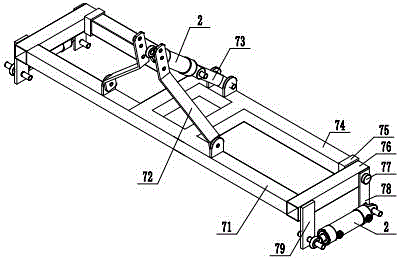

[0020] Reference attached Figure 1~5 The present invention includes a hydraulic frame 7 and a depth-sensing hydraulic control box 12. The depth-sensing hydraulic control box 12 is arranged on the hydraulic frame 7, and the hydraulic frame 7 is composed of a front beam 71, a hydraulic device 2, an upper rod 72. The rear tie rod 73, the rear beam 74, the rear beam fixing plate 75, the cross beam 76, the rear beam winding shaft 77, the rear beam winding plate 78, and the rear beam fixed plate 79 are constituted. The lower end of the upper tie rod 72 is connected to the front beam 71, and the front end of the hydraulic device 2 is connected to On the inner side of the upper end of the front beam 71, the front end of the rear tie rod 73 is connected to the rear end of the hydraulic device 2, the rear end of the rear tie rod 73 is connected to the rear beam 74, the rear beam 74 is connected to the rear beam fixing plate 75, and the rear beam fixing plate 75 is connected to the cross ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com