Animal depilating powdered soap

A soap powder and animal technology, applied in the field of depilatory agents, can solve the problems of inconvenient storage, transportation, waste, poor durability, etc., and achieve the effect of saving preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

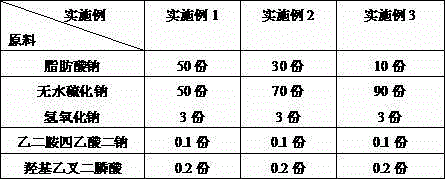

[0032] Weigh each raw material according to the data in Example 1 corresponding to Table 1.

[0033] (1) Preparation of soap base: including adding materials, saponification, separation and purification steps.

[0034] (a) adding materials

[0035] Calculated in proportion by volume, the material is composed of 1 part of lard, 3 parts of 95% ethanol and 3 parts of 40% sodium hydroxide solution, and stirred to make it evenly mixed.

[0036] (b) saponification

[0037] Slowly heat up to keep the reactant in a slightly boiling state, and the saponification reaction time is about 40 min.

[0038] (c) Separation and purification

[0039] After the saponification reaction, slowly pour the product into saturated brine while it is hot, stir while adding, and then place it in an ice-water bath to continue cooling to below room temperature. After standing still for a while, it is found that the soap salts out and floats up. After all the soap is precipitated, it is filtered and drie...

Embodiment 2

[0046] Weigh each raw material according to the data of Example 2 corresponding to Table 1, and then prepare animal depilatory soap powder according to the method of Example 1.

Embodiment 3

[0048] According to the data of Example 3 corresponding to Table 1, each raw material was weighed, and then the animal depilatory soap powder was prepared according to the method of Example 1.

[0049] Table 1 Formula of animal depilatory soap powder (by mass parts)

[0050]

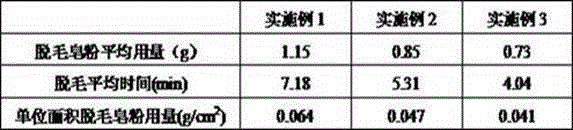

[0051] The method of use of the present invention is as follows: wet the hair on the part to be depilated with water, sprinkle depilatory soap powder on it, rub it properly to dissolve it, and wash it off with clean water after about 4 to 8 minutes.

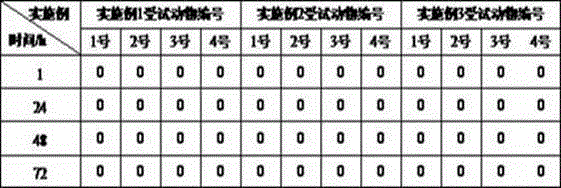

[0052] In order to evaluate the safety and efficacy of the animal depilatory soap powder product prepared in the present invention, an acute skin irritation / corrosion test and a hair removal efficacy test were carried out, and the specific contents are as follows.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com