Preparation method for silicon photocatalyst with 3D multilevel structure

A catalyst and silicon photonics technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of limiting the application of silicon materials, the inability to effectively reduce the reflection of silicon materials, and the energy efficiency is not very significant, etc. problems, to achieve the effect of short preparation period, low cost and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

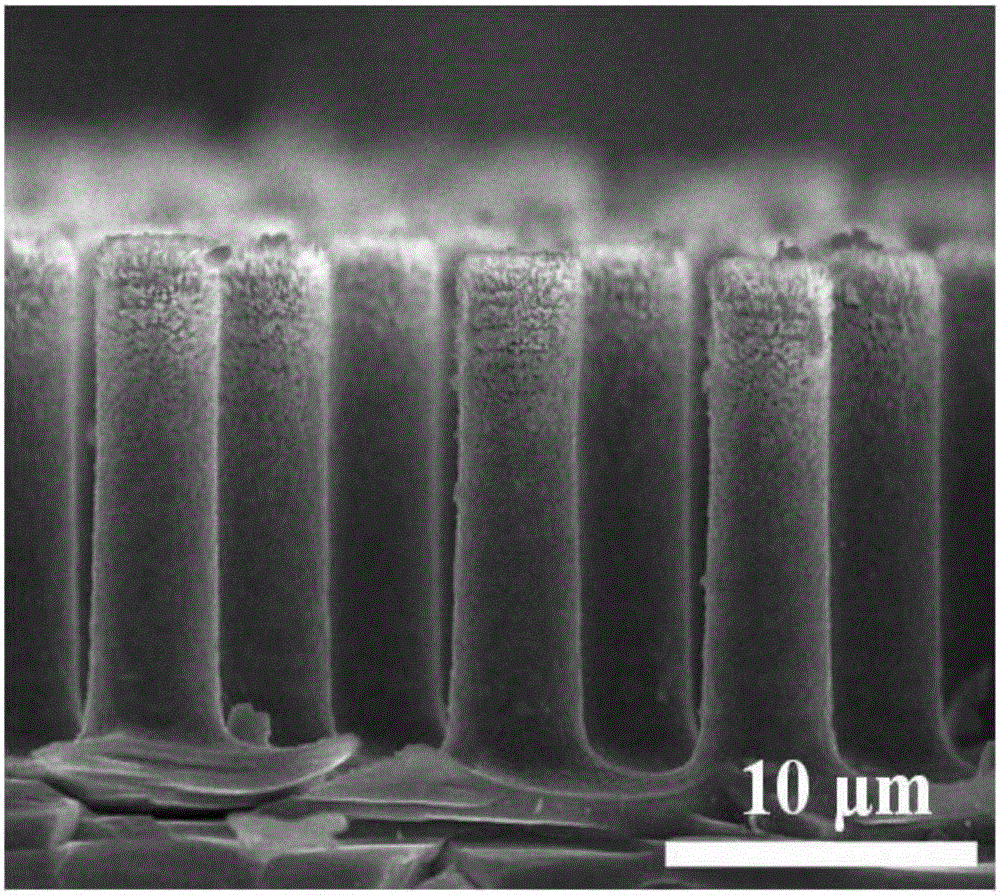

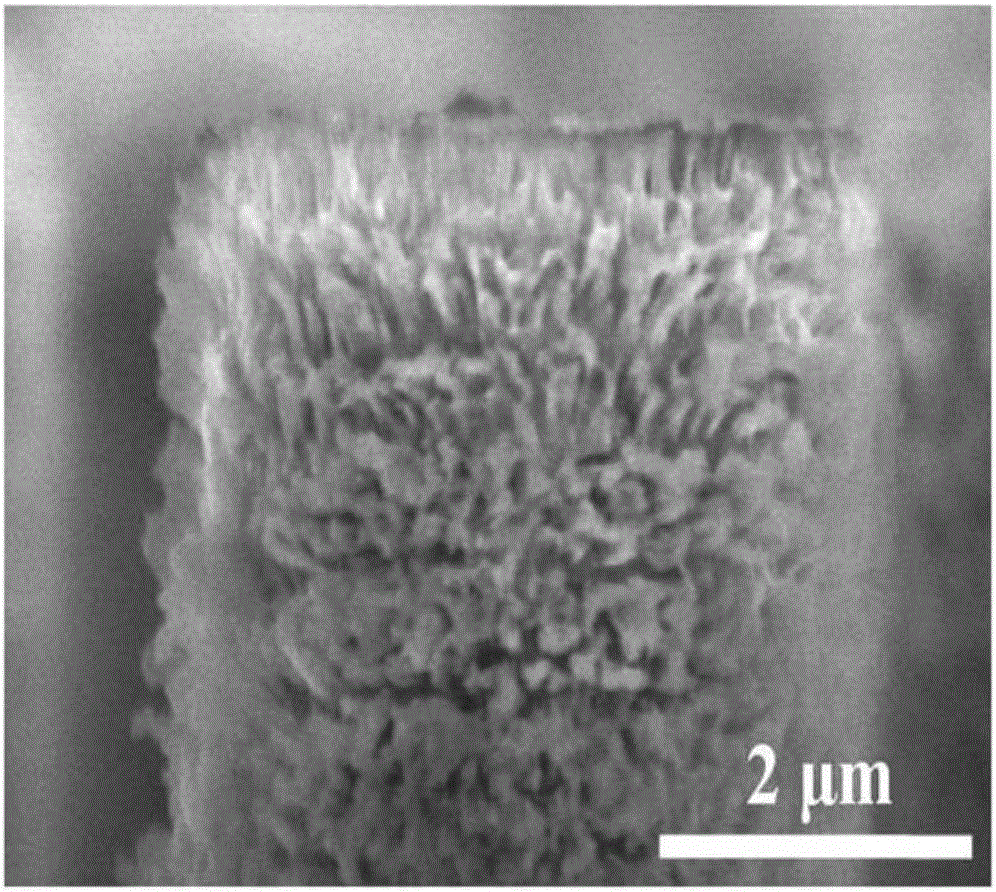

[0026] A method for preparing a silicon photocatalyst with a 3D multilevel structure, the steps are as follows:

[0027] (1) At room temperature, the silicon column array was ultrasonically cleaned in acetone, absolute ethanol and high-purity water, and then the ultrasonically cleaned silicon column array was placed in a volume ratio of 3:1 H 2 SO 4 and H 2 o 2 Soak in the mixed solution for 15 minutes, rinse the obtained silicon column array with high-purity water repeatedly, then place it in 5% HF aqueous solution at room temperature, and soak for 1 minute to remove impurities and natural oxide layer on the silicon surface;

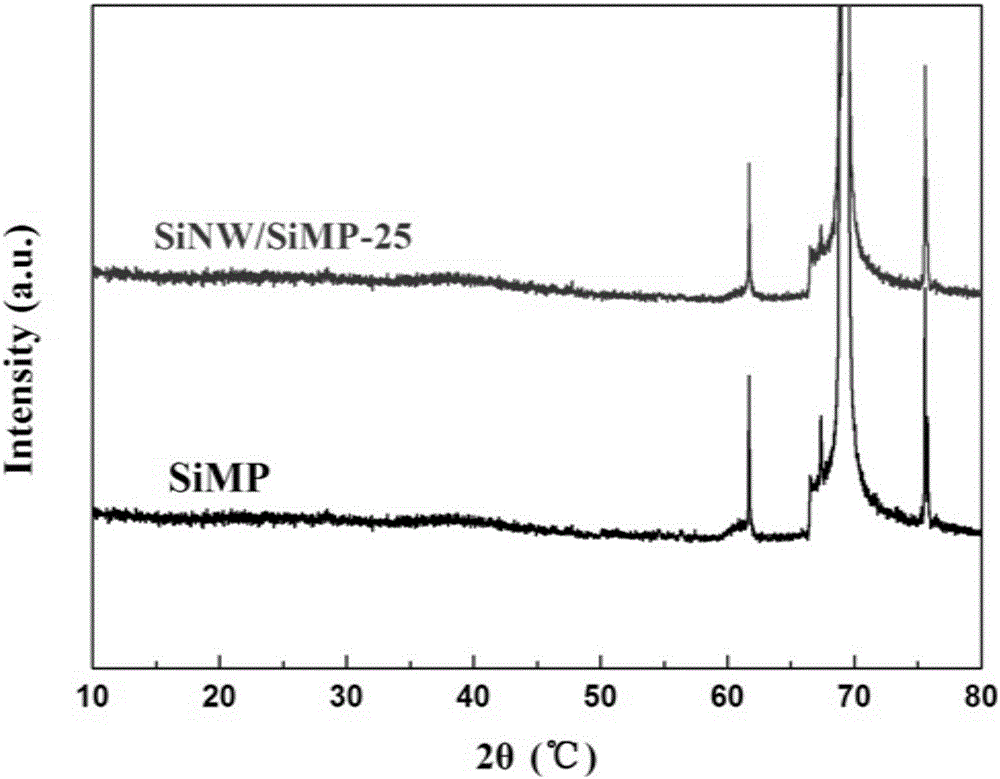

[0028] (2) Place the silicon column array obtained in step (1) into 30mL of 4.2M HF and 0.005M AgNO 3 In the mixed solution, the temperature of the water bath is 30°C, and the etching is performed for 25 minutes to obtain multi-level silicon;

[0029] (3) The multi-level silicon obtained in step (2) was washed repeatedly with high-purity water, and ...

Embodiment 2

[0036] (1) At room temperature, the silicon column array was ultrasonically cleaned in acetone, absolute ethanol and high-purity water, and then the ultrasonically cleaned silicon column array was placed in a volume ratio of 3:1 H 2 SO 4 and H 2 o 2 Soak in the mixed solution for 15 minutes, rinse the obtained silicon column array with high-purity water repeatedly, and then place it in an aqueous HF solution with a volume fraction of 5% at room temperature, and soak for 1 minute to remove impurities and natural oxide layers on the silicon surface;

[0037](2) Place the silicon column array obtained in step (1) into 30mL of 4.2M HF and 0.005M AgNO 3 In the mixed solution, the temperature of the water bath is 30°C, and the etching is performed for 10 minutes to obtain multi-level silicon;

[0038] (3) The multi-level silicon obtained in step (2) was washed repeatedly with high-purity water, and then placed in 20 mL of HNO with a molar concentration of 7.66M 3 In the aqueous ...

Embodiment 3

[0041] (1) At room temperature, the silicon column array was ultrasonically cleaned in acetone, absolute ethanol and high-purity water, and then the ultrasonically cleaned silicon column array was placed in a volume ratio of 3:1 H 2 SO 4 and H 2 o 2 Soak in the mixed solution for 15 minutes, rinse the obtained silicon column array with high-purity water repeatedly, and then place it in an aqueous HF solution with a volume fraction of 5% at room temperature, and soak for 1 minute to remove impurities and natural oxide layers on the silicon surface;

[0042] (2) Place the silicon column array obtained in step (1) into 30mL of 4.2M HF and 0.005M AgNO 3 In the mixed solution, the temperature of the water bath is 30°C, and the etching is carried out for 20 minutes to obtain multi-level silicon;

[0043] (3) The multi-level silicon obtained in step (2) was washed repeatedly with high-purity water, and then placed in 20 mL of HNO with a molar concentration of 7.66M 3 In the aqueo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com